Two-stage dry-type gas filtering tank body respirator device and cleaning method thereof

A respirator, dry technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as difficult to find, time-consuming, tank inward depression, etc., to improve air filtration efficiency and operational safety Reliable, the effect of increasing the membrane filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

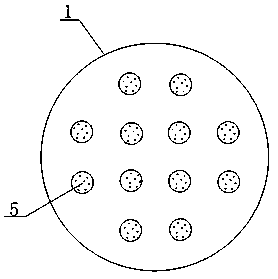

[0045] Such as Figure 1~2 As shown, a two-stage dry gas filter tank respirator device includes a housing 1, a coarse filter disc 2 positioned at the top of the housing 1, a tank connecting pipe 3 positioned at the bottom end of the housing 1, and the coarse filter disc 2 Breathing holes 4 are arranged on the top, and microporous membrane filter element 5, steam heating coil 6, vacuum breaking tube 71 and vacuum breaking respirator 7 are also included. Microporous membrane filter element 5 and microporous membrane filter element 5 The upper end of the filter element is provided with a fixed net plate 51, and the lower end is provided with a lower fixed plate 52 of the filter element, and the upper fixed net plate 51 of the filter element and the lower fixed plate 52 of the filter element are respectively connected on the inner side wall of the housing 1; the steam heating coil 6 is provided with In the housing 1 and above the fixed mesh plate 51 on the filter element; a vacuum...

Embodiment 2

[0058] Such as Figure 3-4 As shown, a two-stage dry gas filter tank respirator device includes a housing 1, a coarse filter disc 2 positioned at the top of the housing 1, a tank connecting pipe 3 positioned at the bottom end of the housing 1, and the coarse filter disc 2 Breathing holes 4 are arranged on the top, and microporous membrane filter element 5, steam heating coil 6, vacuum breaking tube 71 and vacuum breaking respirator 7 are also included. Microporous membrane filter element 5 and microporous membrane filter element 5 The upper end of the filter element is provided with a fixed net plate 51, and the lower end is provided with a lower fixed plate 52 of the filter element, and the upper fixed net plate 51 of the filter element and the lower fixed plate 52 of the filter element are respectively connected on the inner side wall of the housing 1; the steam heating coil 6 is provided with In the housing 1 and above the fixed mesh plate 51 on the filter element; a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com