Processing method of wet-method black silicon wafer and preparation method of wet-method black silicon wafer

A processing method and technology of silicon wafers, applied in the field of solar cells, can solve problems such as poor product quality, low production capacity, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a wet-process black silicon wafer, comprising the following steps:

[0046] a) Texturing the silicon wafer with the texturing solution to obtain the texturized silicon wafer;

[0047] b) performing demetallization treatment on the textured silicon wafers to obtain demetallized silicon wafers;

[0048] The demetallization treatment is the treatment method described in the above technical scheme;

[0049] c) post-processing the demetallized silicon wafer to obtain a silicon wafer product.

[0050] Wherein, the source, type, etc. of the texturing liquid are consistent with those described in the above technical solution, and will not be repeated here. The conditions for making texture etc. are consistent with those described in the above technical solution, and will not be repeated here. The demetallization treatment in step b) is consistent with that described in the above technical solution, and will not be re...

Embodiment 1

[0057] (1) Preparation of textured silicon wafers

[0058] Place the polysilicon wafer with a clean surface in a mixed solution of hydrofluoric acid, hydrogen peroxide and silver nitrate, wherein the concentration of hydrofluoric acid is 8%, the concentration of hydrogen peroxide is 15%, and the concentration of silver nitrate is 1%; ) after soaking for 3 minutes, take it out and wash it with deionized water to obtain a textured silicon wafer.

[0059] (2) Demetallization treatment

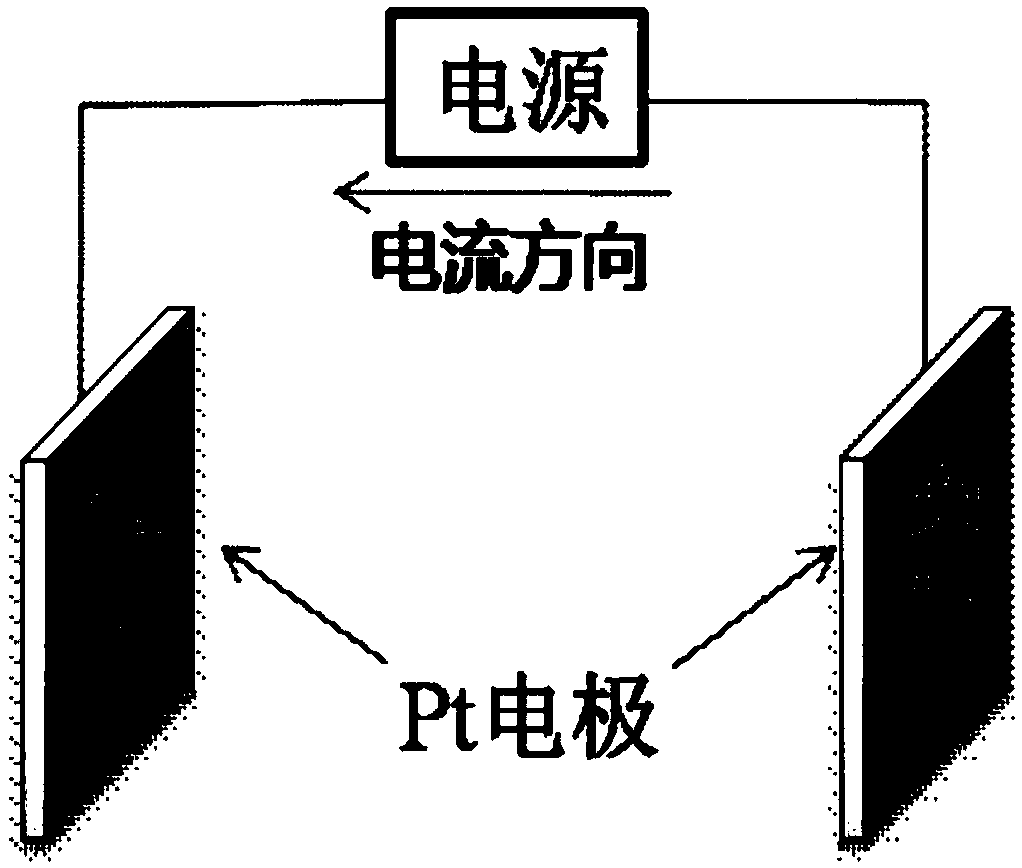

[0060] Texture silicon chip is placed in the nitric acid solution (300L) that concentration is 65%, and introduces electrochemical device, and in electrochemical device, working electrode is Pt sheet, negative electrode is Pt sheet, control voltage is 10V, under room temperature (30 °C) for an electrochemical reaction. Among them, the structure diagram of the electrochemical device is shown in figure 1 as shown, figure 1 It is the structural diagram of the electrochemical device in Example 1, ...

Embodiment 2

[0065] (1) Preparation of textured silicon wafers

[0066] The polysilicon wafer with a clean surface is placed in a mixed solution of hydrofluoric acid, hydrogen peroxide and copper nitrate, wherein the concentration of hydrofluoric acid is 10%, the concentration of hydrogen peroxide is 20%, and the concentration of copper nitrate is 2%. ) after soaking for 3 minutes, take it out and wash it with deionized water to obtain a textured silicon wafer.

[0067] (2) Demetallization treatment

[0068] Texture silicon chip is placed in the nitric acid solution (300L) that concentration is 65%, and introduces electrochemical device, and in electrochemical device, working electrode is Pt sheet, negative electrode is Pt sheet, control voltage is 10V, under room temperature (30 °C) for an electrochemical reaction. .

[0069] Blank control treatment: carried out according to the above-mentioned demetallization treatment process, the difference is that no electrochemical device is intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com