High-strength steel and snap ring manufacturing method

A technology of high-strength steel and manufacturing method, which is applied in the field of parts manufacturing, can solve problems such as matching and difficult super-high-strength parts, and achieve the effects of improving strength and toughness, improving drawing performance, and good elasticity and torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]The specific operation method for the preparation of the high-strength steel and wire rod in the above step 2 is as follows: a. Put the raw materials prepared in the step 1 into the electric arc furnace for smelting; b. Refining in the LF furnace; c. Vacuum degassing; d. billet continuous casting; e. billet rolling; f. high-speed wire rod rolling; when performing the step f. The rolling temperature is 910-980°C, and the spinning temperature is 780-880°C, so as to ensure that the rolled wire structure is a fine and uniform sorbite structure, which is beneficial to the drawing performance of the wire rod. In the preferred solution of the present invention, step d is continuous casting of a round billet with a diameter of 380mm, said step e is rolling a 150mm×150mm square billet, and said step f rolls a wire rod with a diameter of 10mm.

[0039] The specific operation of the above step 4: annealing is: protective atmosphere spheroidizing annealing; the specific operation of...

Embodiment 1

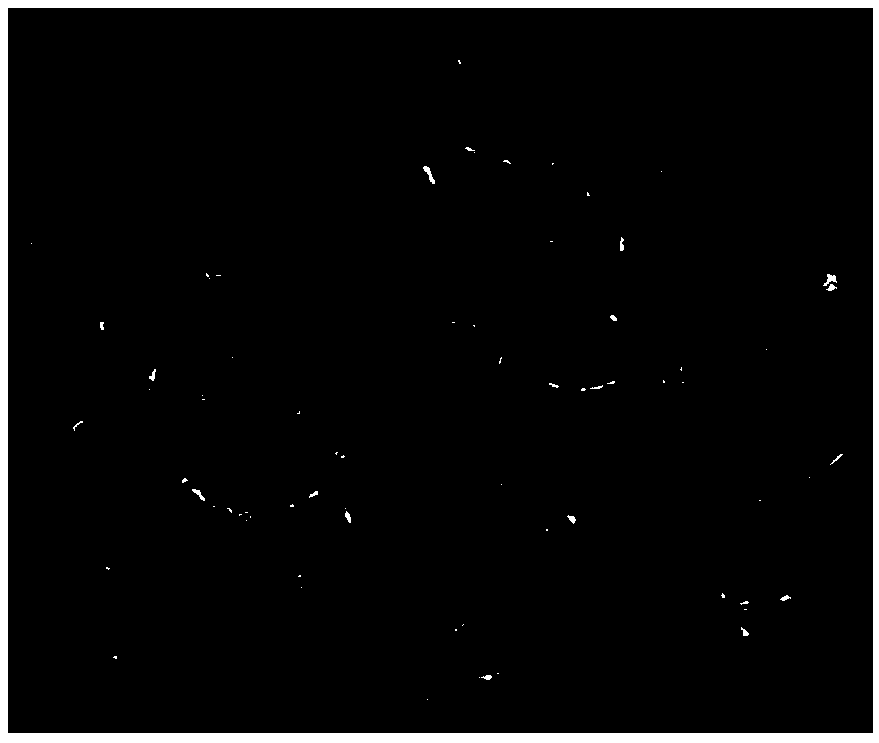

[0041] Example 1, the proportion of high-strength steel is C: 0.78%, Si: 1.03%, Mn: 0.73%, Nb: 0.040%, S: 0.002%, P: 0.008%, T.O: 13ppm, Alt: 0.005%, The rest are Fe and unavoidable impurity elements, as shown in Table 1. Manufacture the snap ring according to the above steps, wherein the diameter of the continuous casting round billet is 380mm, the size of the rolled square billet is 150mm×150mm, and the specification of the wire rod is 10mm; the heating temperature for the wire rod rolling is 1065°C, and the rolling The rolling temperature is 978°C, the final rolling temperature is 915°C, and the spinning temperature is 792°C. As shown in Table 2, the rolled wire rod has a fine and uniform sorbite structure, as shown in Table 2. figure 1 As shown; the quenching temperature is 860°C and the tempering temperature is 440°C during the heat treatment of the snap ring. Elastic snap rings with good elasticity and torsion performance and a hardness range of 52HRC to 56HRC, as shown...

Embodiment 2

[0042] Example 2, the proportion of high-strength steel is C: 0.80%, Si: 0.98%, Mn: 0.72%, Nb: 0.042%, S: 0.003%, P: 0.008%, T.O: 12ppm, Alt: 0.005%, The rest are Fe and unavoidable impurity elements, as shown in Table 1. Manufacture the snap ring according to the above steps, wherein the diameter of the continuous casting round billet is 380mm, the size of the rolled square billet is 150mm×150mm, and the specification of the wire rod is 10mm; The rolling temperature is 975°C, the final rolling temperature is 918°C, and the spinning temperature is 789°C. As shown in Table 2, the rolled wire rod has a fine and uniform sorbite structure, as shown in Table 2. figure 2 As shown; the quenching temperature is 860°C and the tempering temperature is 440°C during the post-treatment of the snap ring. The elastic clasp with good elasticity and torsional property and hardness range of 52HRC to 56HRC is obtained, as shown in Table 3 and Figure 4 shown. Among them, the microstructure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com