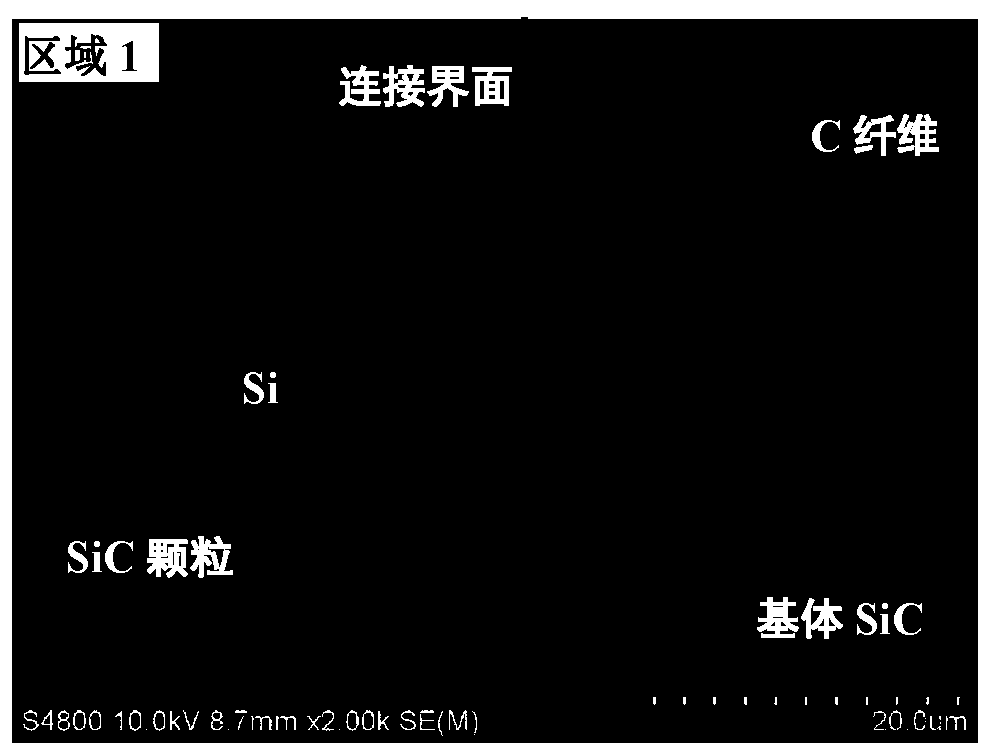

Reactive sintering Cf/SiC composite material and synchronous reaction connection method

A composite material and connecting layer technology, which is applied in the field of organic resin carbon source and online connection process to realize Cf/SiC composite material connection, can solve the problems of material deformation, adverse effect of composite material connection performance, cracking, etc. Excellent high temperature performance and good thermal property matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A reaction sintering C f / SiC composite material synchronous reaction connection method, comprising the following steps:

[0033] 1) Preparation of resin-based slurry:

[0034] a. Prepare raw materials according to the following ratio:

[0035] 35% of phenolic resin, 35% of ethanol, 30% of silicon carbide micropowder; The particle size is 0.5 μm.

[0036] b. Add ethanol to the phenolic resin, stir to fully dissolve it, and configure the phenolic resin solution;

[0037] c. adding silicon carbide micropowder to the phenolic resin solution to form a slurry;

[0038] d. Add polyvinylpyrrolidone as a dispersant, then ball mill the slurry for 12 hours, and vacuum degass it for 2 hours to obtain a binder.

[0039] 2) Preparation of parts to be connected: prepare at least two reaction sintering C f / SiC process without SiC f / C material is used as the part to be connected, and the surface to be connected is ground with a grinder to remove impurities on the surface to be...

Embodiment 2

[0043] In this embodiment, it is basically the same as Example 1, the difference is:

[0044] Prepare resin-based slurry in step 1):

[0045] a. 30% phenolic resin, 30% ethanol, 40% silicon carbide micropowder; and, the dispersant polyvinylpyrrolidone with 4% of the main component by weight, and the curing agent with 4% of the main component by weight; wherein, silicon carbide The particle size of the fine powder is 1 μm.

Embodiment 3

[0047] In this embodiment, it is basically the same as Example 1, the difference is:

[0048] Preparation of resin-based slurry in step 1): as a carbon source in the binder and reactive siliconizing process:

[0049] a. Prepare raw materials according to the following ratio:

[0050] 25% of phenolic resin, 25% of ethanol, 50% of silicon carbide micropowder; and, the dispersant polyvinylpyrrolidone of 4% of the main component by weight, and the curing agent of 4% of the main component by weight; wherein, silicon carbide micropowder The particle size is 0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com