High-content buckwheat fine dried noodles and preparation method thereof

A production method and high-content technology, applied in dough processing, dough forming and cutting equipment, food ingredients as anti-microbial preservation, etc., can solve the problems of inability to roll, high broken rate, etc., to extend the shelf life, improve quality, The effect of improving the utilization rate of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of pretreated buckwheat whole flour

[0059] 1) Insecticidal sterilization of buckwheat grains

[0060] Mix clean buckwheat grains with a certain amount of slightly acidic electrolyzed water. The effective chlorine concentration of the slightly acidic electrolyzed water is 30ppm and the pH is 6.2, so that the final moisture of the buckwheat grains is 13.0wt%. Put the treated buckwheat grains into the microwave In the equipment, the temperature is 80℃ for 5min.

[0061] 2) Stone milling powder

[0062] Put the pretreated buckwheat grains into a stone mill and grind multiple times to obtain whole buckwheat flour.

[0063] 3) Superfine grinding

[0064] Put the whole buckwheat flour into an ultrafine pulverizer and pulverize for 10 minutes to obtain whole buckwheat flour of 80 mesh.

[0065] (2) Making noodles

[0066] 1) Dry powder mix

[0067] Weigh 60 kg of buckwheat flour, 30 kg of high-gluten wheat flour, 15 kg of resistant starch, 5 kg of gluten powder, 0.5 kg of ...

Embodiment 2

[0079] (1) Preparation of pretreated buckwheat whole flour

[0080] 1) Insecticidal sterilization of buckwheat grains

[0081] Mix clean buckwheat grains with ozone water with an ozone concentration of 2.53mg / L to make the final moisture of buckwheat grains 14.3wt%, and place the processed buckwheat grains on the conveyor belt in the center of the lower plate of the radio frequency processing chamber. It is 20mm, operating frequency is 27.12MHz, power is 5Kw, electrode spacing is 40mm, processing time is 180s, the conveyor belt reciprocates for radio frequency insecticide treatment, and the temperature of buckwheat grains out of the radio frequency cavity is controlled at 50°C.

[0082] 2) Stone milling powder

[0083] Put the pretreated buckwheat grains into a stone mill and grind multiple times to obtain whole buckwheat flour.

[0084] 3) Low temperature vortex crushing

[0085] Put the whole buckwheat flour into a low-temperature vortex pulverizer at 35°C for 10 minutes to obtain a u...

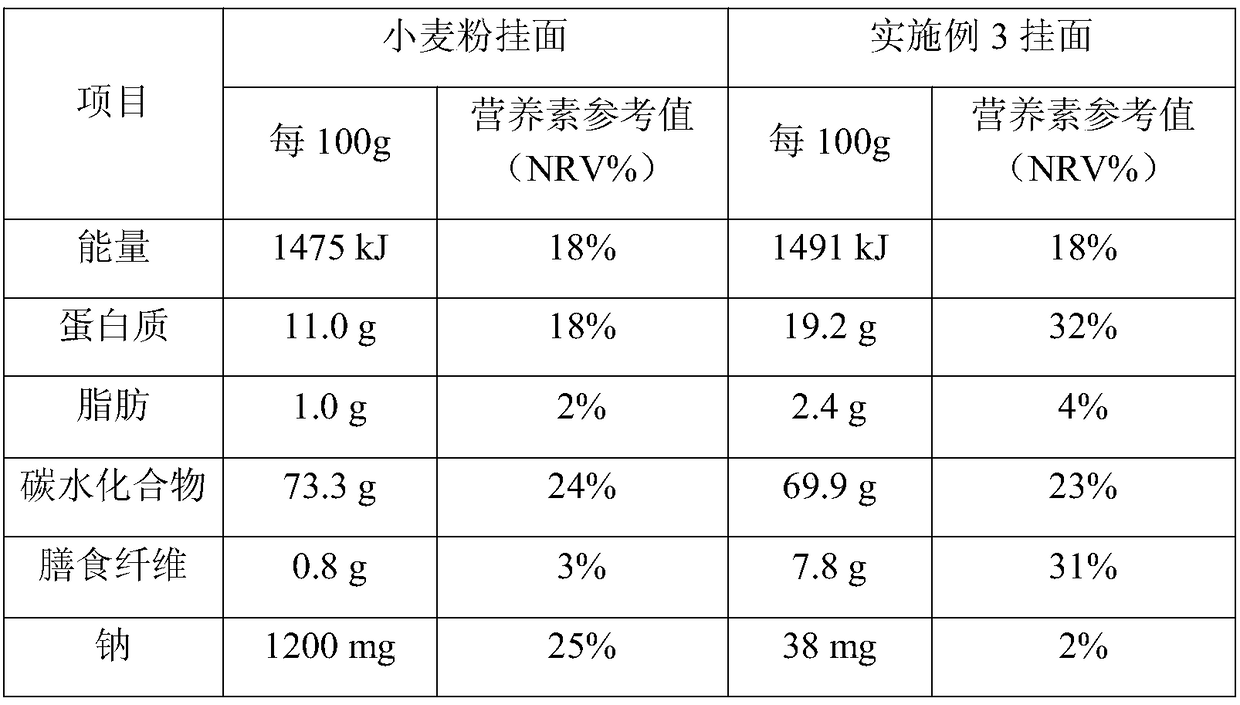

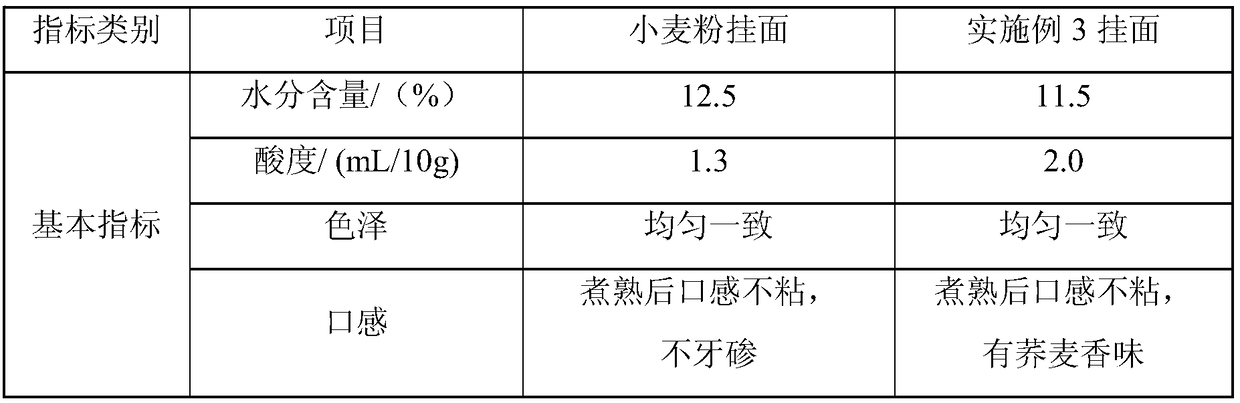

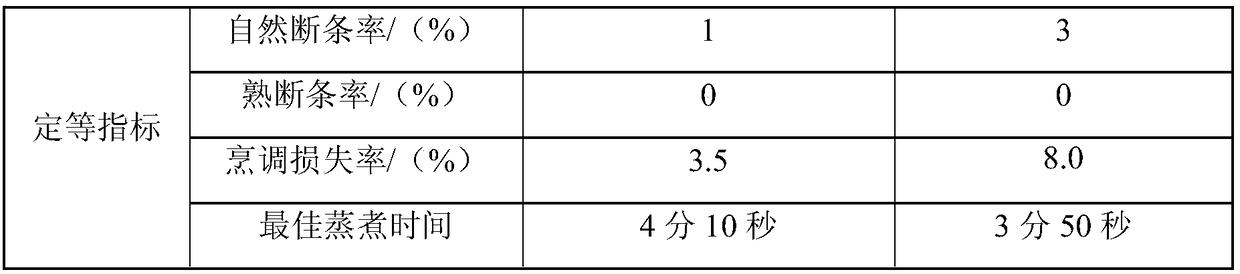

Embodiment 3

[0099] (1) Preparation of pretreated buckwheat whole flour

[0100] 1) Insecticidal sterilization of buckwheat grains

[0101] Mix clean buckwheat grains with a certain amount of slightly acidic electrolyzed water. The effective chlorine concentration of the slightly acidic electrolyzed water is 60ppm and the pH is 6.10, so that the final moisture of the buckwheat grains is 15.0wt%, and the treated buckwheat grains are placed in On the conveyor belt at the center of the electrode plate under the radio frequency processing chamber, the sample thickness is 30mm, the working frequency is 45MHz, the power is 9Kw, the electrode spacing is 80mm, and the radio frequency processing time is 300s. The conveyor belt reciprocates for radio frequency insecticide treatment, and the buckwheat grains are The temperature of the RF cavity is controlled at 65°C.

[0102] 2) Roll milling machine powder

[0103] The pretreated buckwheat grains are put into a roller mill for pulverization, and sieved to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com