Surface-modified high-nickel ternary positive material, preparation thereof, and battery prepared from surface-modified high-nickel ternary positive material

A positive electrode material and surface modification technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as hindering the diffusion of lithium ions, hindering the diffusion of electrolytes, and chemical instability, so as to suppress irreversible capacity loss and improve lithium Ion Diffusion Issues, Effect of Fast Li-Ion Migration Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The positive electrode material of this embodiment is a high-nickel ternary positive electrode material (molecular formula: LiNi 0.88 co 0.09 Al 0.03 o 2 ) The surface of the nucleus forms 0.5% (mass fraction) of the average particle size of 50nm nano-oxide YSZ (Zr 0.92 Y 0.08 o 1.96 ) and 0.5% (mass fraction) of 50nm nano-oxide alumina (MnO 2 ) surface modification layer.

[0041] Its preparation method is as follows:

[0042] Take by weighing 300.0g high-nickel ternary positive electrode material (LiNi 0.88 co 0.09 Al 0.03 o 2 ), 1.500g nano oxide YSZ (Zr 0.92 Y 0.08 o 1.96 ), 1.500g nano-oxide manganese dioxide (MnO 2 ), using a mechanical fusion machine. After mixing for 5 minutes to coat evenly, and then heat-treating at 600° C. for 4 hours in an oxygen atmosphere, a surface-modified high-nickel ternary cathode material can be obtained.

[0043] The electrochemical performance test is as follows:

[0044] Mix the target product with the conductive ...

Embodiment 2

[0047] The positive electrode material of this embodiment is a high-nickel ternary positive electrode material (molecular formula: LiNi 0.88 co 0.09 Al 0.03 o 2 ) The surface of the nucleus forms 1% (mass fraction) of nano-oxide YSZ (Zr 0.82 Y 0.18 o 1.91 ) and 0.5% (mass fraction) of 50nm nano-oxide manganese dioxide (MnO 2 ) surface modification layer.

[0048] Its preparation method is as follows:

[0049] Take by weighing 300.0g high-nickel ternary positive electrode material (LiNi 0.88 co 0.09 Al 0.03 o 2 ), 3.000g nano oxide YSZ (Zr 0.92 Y 0.08 o 1.96 ), 1.500g nano-oxide manganese dioxide (MnO 2 ), coated uniformly by mechanical fusion, and then heat-treated at 600°C for 4 hours in an oxygen atmosphere to obtain a surface-modified high-nickel ternary cathode material. The scanning electron microscope pictures of the material are shown in figure 1 .

[0050] Electrochemical performance test is the same as embodiment 1;

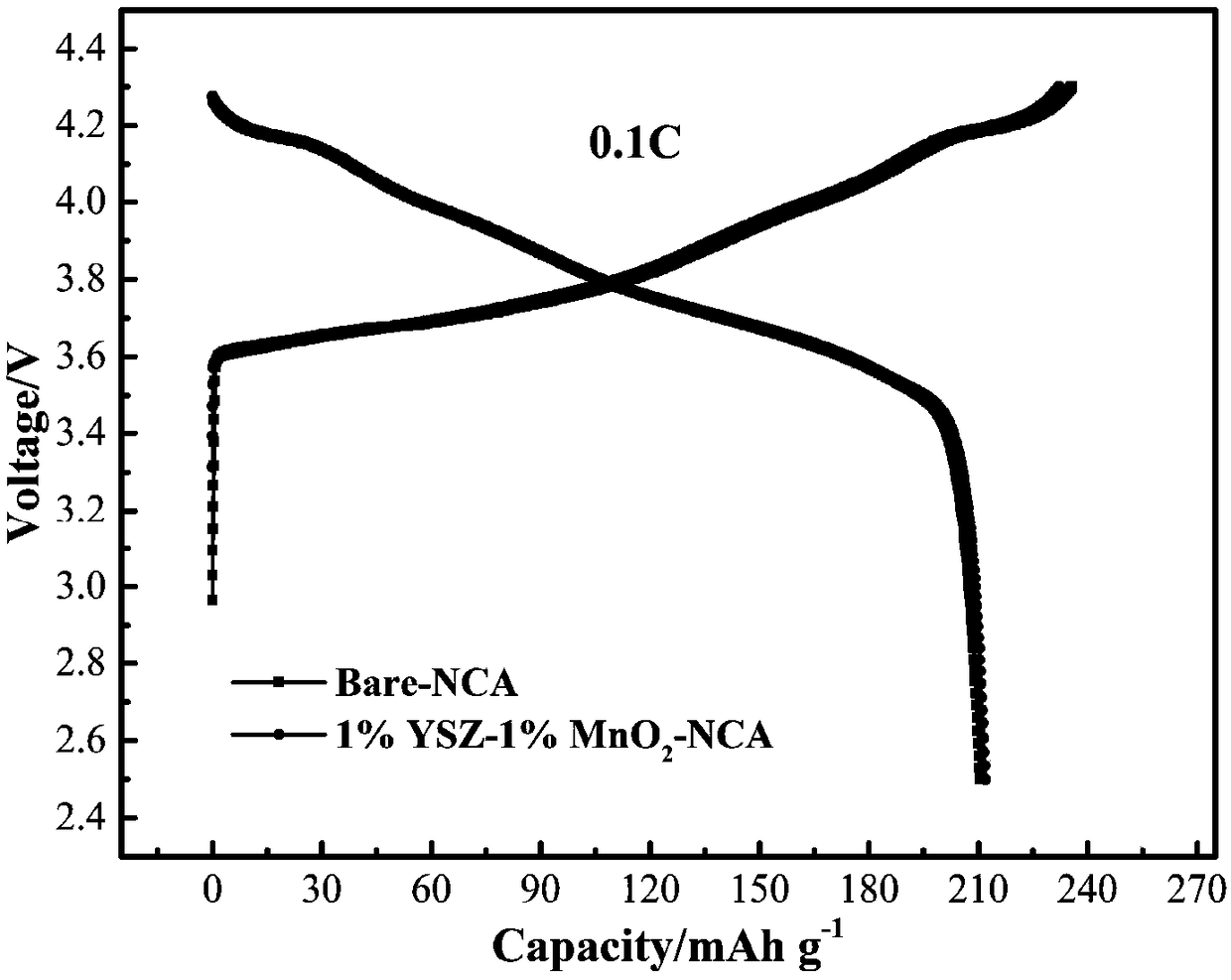

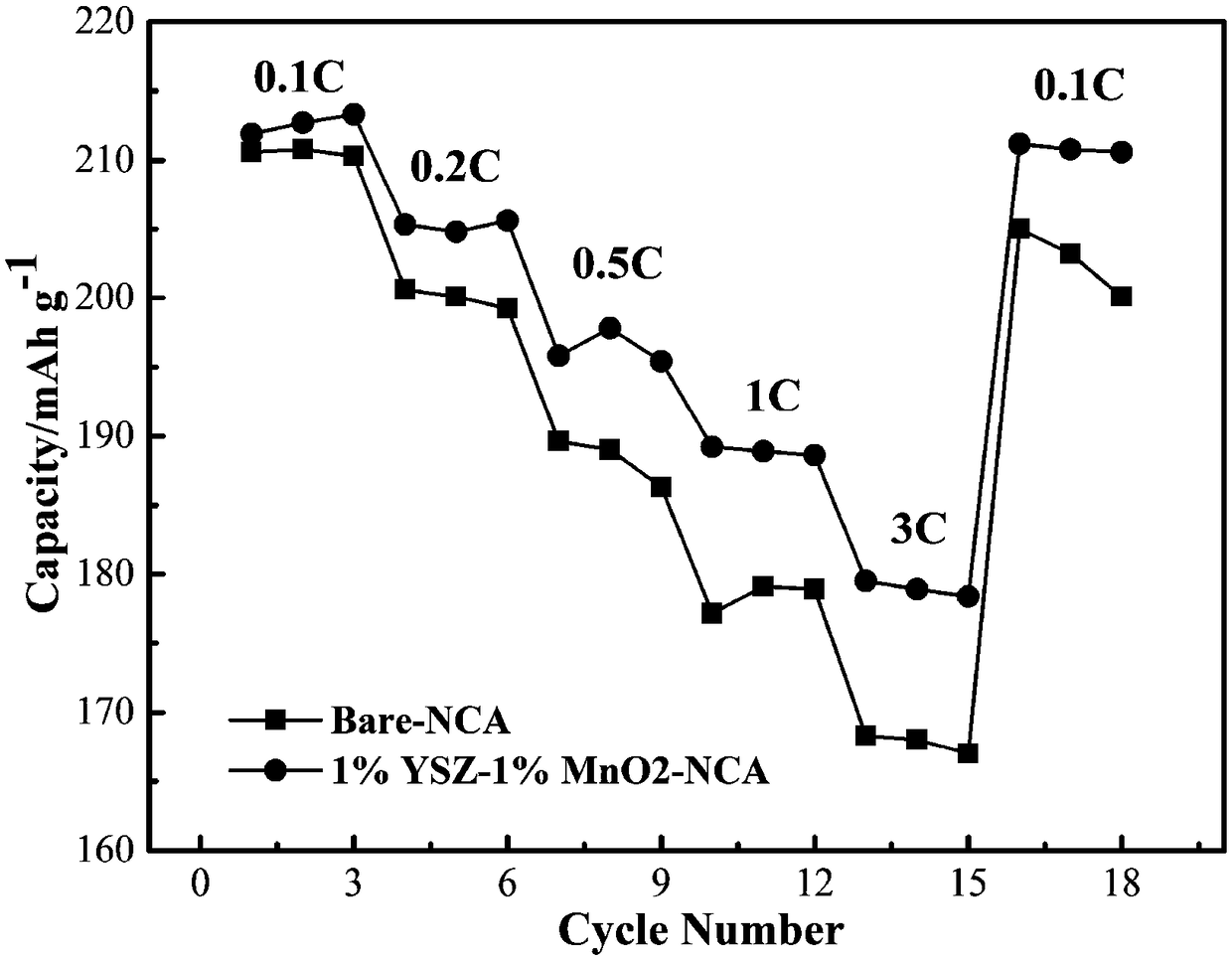

[0051] Electrochemical tests sho...

Embodiment 3

[0053] The positive electrode material of this embodiment is a high-nickel ternary positive electrode material (molecular formula: LiNi 0.88 co 0.09 Al 0.03 o 2 ) The surface of the nucleus forms 1% (mass fraction) of nano-oxide YSZ (Zr 0.92 Y 0.08 o 1.96 ) and 0.5% (mass fraction) of manganese phosphate (Mn 3 (PO 4 ) 2 ) surface modification layer.

[0054] Its preparation method is as follows:

[0055] Take by weighing 300.0g high-nickel ternary positive electrode material (LiNi 0.88 co 0.09 Al 0.03 o 2 ), 3.000g nano oxide YSZ (Zr 0.92 Y 0.08 o 1.96 ), 1.500g manganese phosphate (Mn 3 (PO 4 ) 2 ), coated uniformly by mechanical fusion, and then heat-treated at 600°C for 4 hours in an oxygen atmosphere to obtain a surface-modified high-nickel ternary cathode material.

[0056] Electrochemical performance test is the same as embodiment 1;

[0057] Electrochemical tests show that the first charge and discharge specific capacities are 234.3 and 210.9mAh g in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com