Passivation solution suitable for processing aluminum foil of aluminum-plastic film

A technology of aluminum-plastic film and passivation solution, which is applied in the coating process of metal materials, can solve problems such as environmental pollution, harm to human health, and weak bonding force, and achieve simple processing technology, high lamination strength, and material economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

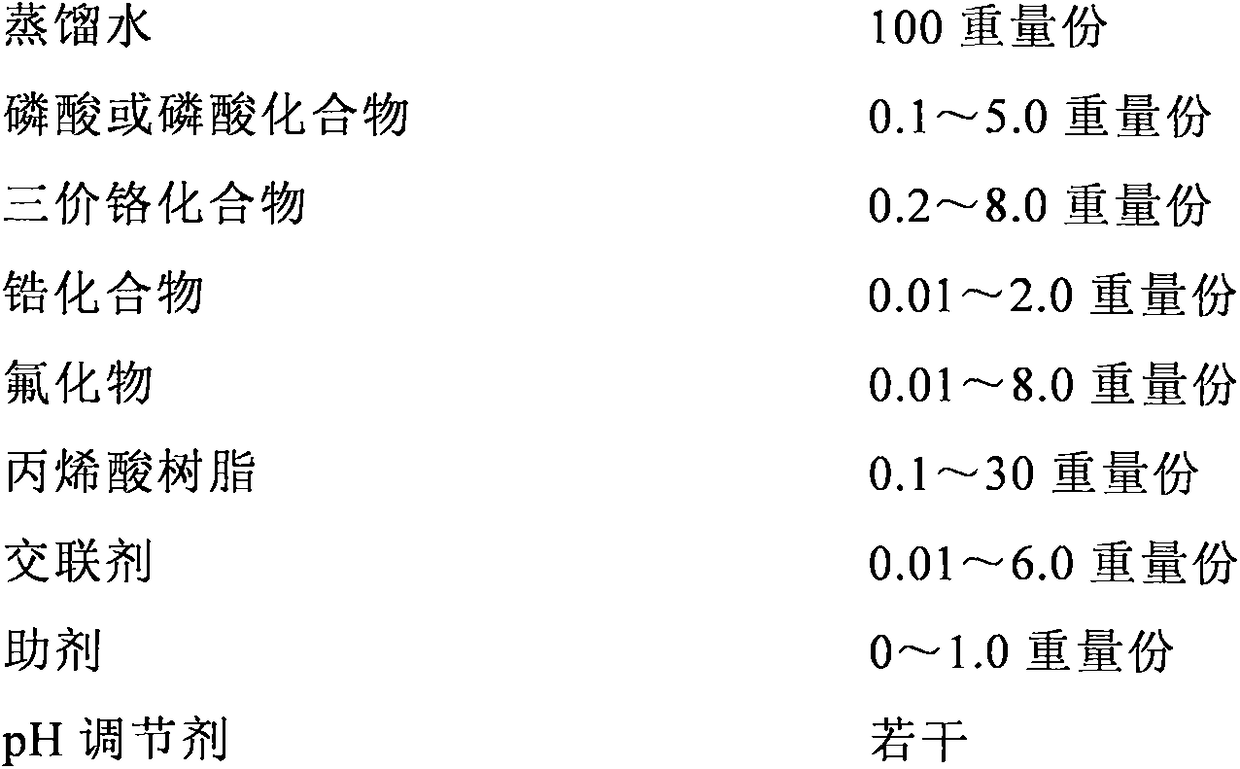

[0038] Composition of passivation solution:

[0039]

[0040] After the passivation solution is prepared, 9 g of ethanol is added to it, and the mixture is evenly mixed for later use.

[0041] Take the degreased 8021 aluminum foil (thickness 40um), apply the mixed solution on the bright surface of the aluminum foil with a 6um wire rod, the baking temperature is 160 degrees, and the baking time is 2min. Then, the treated aluminum foil was laminated with CPP (40um) with modified polyolefin-based glue and cured by dry lamination method, and then the peeling force, water resistance and electrolyte resistance were measured. Salt spray resistance of aluminum foil.

Embodiment 2

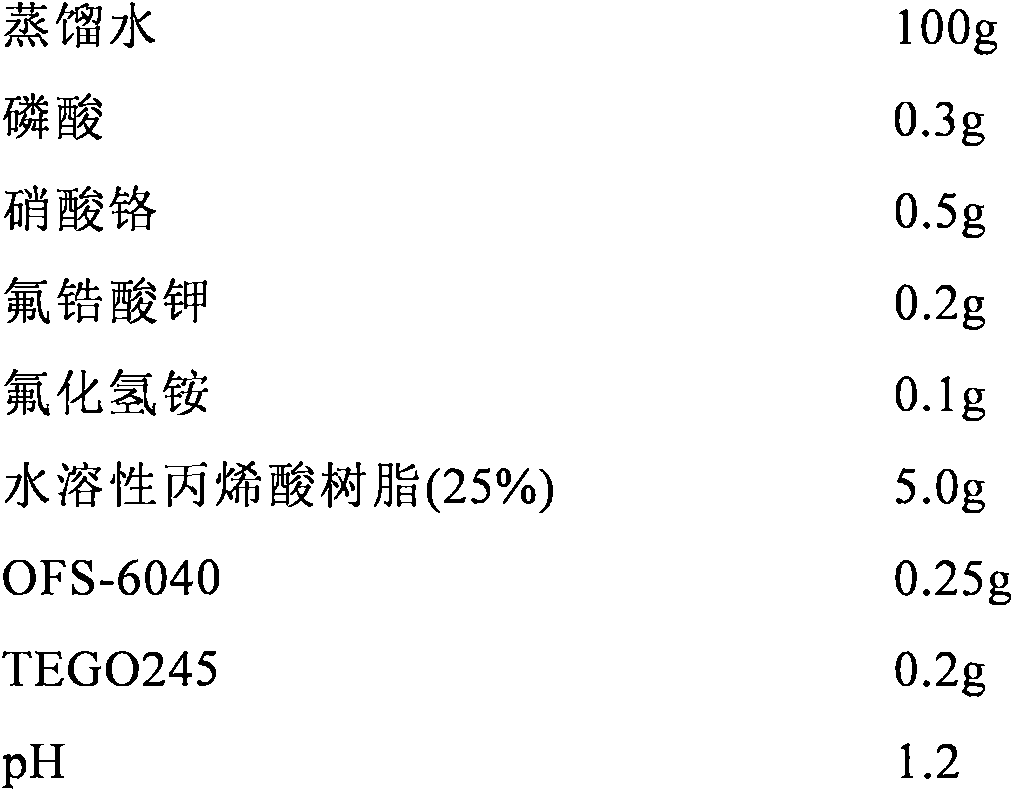

[0043] Composition of passivation solution:

[0044]

[0045]

[0046] After the passivation solution is prepared, 9 g of ethanol is added to it, and the mixture is evenly mixed for later use.

[0047] Take the degreased 8021 aluminum foil (thickness 40um), use a 6um wire rod to coat the mixture on the bright surface of the aluminum foil, the baking temperature is 180 degrees, and the baking time is 1 min. Then, the treated aluminum foil was laminated with CPP (40um) with modified polyolefin-based glue and cured by dry lamination method, and its peel force, water resistance and electrolyte resistance were measured. The salt spray resistance of aluminum foil.

Embodiment 3

[0049] Composition of passivation solution:

[0050]

[0051] After the passivation solution is prepared, 9 g of ethanol is added to it, and the mixture is evenly mixed for later use.

[0052] Take the degreased 8021 aluminum foil (thickness 40um), apply the mixed solution on the bright surface of the aluminum foil with a 6um wire rod, the baking temperature is 200 degrees, and the baking time is 40s. Then, the treated aluminum foil was laminated with CPP (40um) with modified polyolefin-based glue and cured by dry lamination method, and its peel force, water resistance and electrolyte resistance were measured. The salt spray resistance of aluminum foil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com