High-mechanical-strength aramid nanofiber hybrid thin film and preparation method thereof

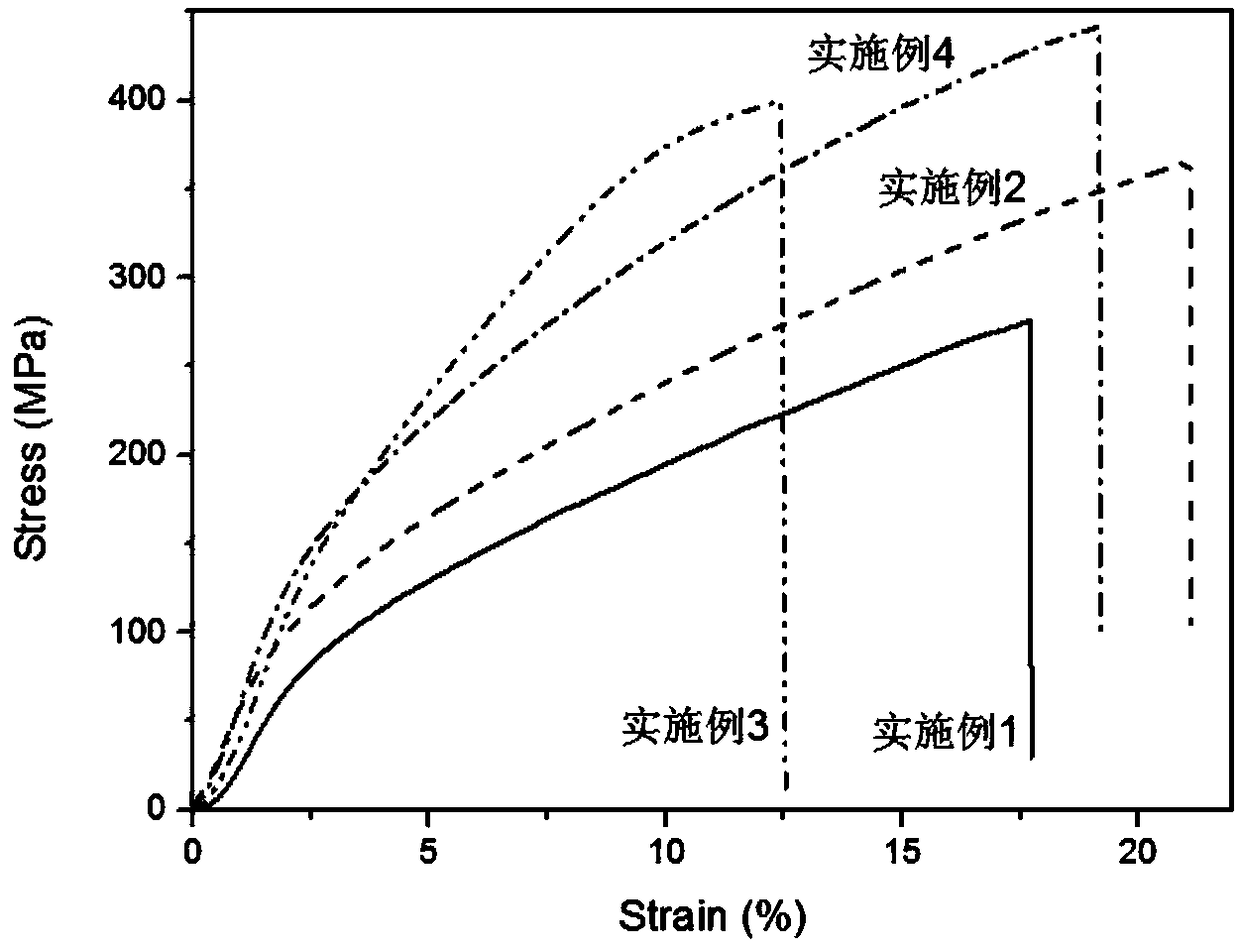

A nanofiber and aramid fiber technology, which is applied in the field of aramid fiber hybrid film and its preparation, can solve the problems such as the reduction of elongation at break, and achieve the improvement of elongation at break, the improvement of mechanical properties, and the improvement of Young's modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1 g of aramid fiber yarn and 1.5 g of potassium hydroxide were weighed and put into a reactor, DMSO solution was added, and stirred at a temperature of 25° C. for 7 days to obtain an aramid nanofiber solution.

[0027] Weigh 3g of graphite powder and 18g of potassium permanganate into the reactor, slowly add mixed acid (concentrated sulfuric acid: 360mL, concentrated phosphoric acid: 40mL), and stir until uniform. The reaction system was transferred to a water bath, and stirred at a constant temperature of 50° C. for 12 h. Subsequently, the reaction solution was poured onto 400 mL of ice, stirring was continued, and hydrogen peroxide (30 wt.%) was added dropwise until the reaction solution turned bright yellow. The reaction solution was filtered while hot and washed with 1:10 dilute hydrochloric acid. The product was subjected to high-speed centrifugation and repeated water washing until it was close to neutral, and was ultrasonically treated for more than 1 hour with ...

Embodiment 2

[0030] 1 g of aramid fiber yarn and 1.5 g of potassium hydroxide were weighed and put into a reactor, DMSO solution was added, and stirred at a temperature of 25° C. for 7 days to obtain an aramid nanofiber solution.

[0031] Weigh 3g of graphite powder and 18g of potassium permanganate into the reactor, slowly add mixed acid (concentrated sulfuric acid: 360mL, concentrated phosphoric acid: 40mL), and stir until uniform. The reaction system was transferred to a water bath, and stirred at a constant temperature of 50° C. for 12 h. Subsequently, the reaction solution was poured onto 400 mL of ice, stirring was continued, and hydrogen peroxide (30 wt.%) was added dropwise until the reaction solution turned bright yellow. The reaction solution was filtered while hot and washed with 1:10 dilute hydrochloric acid. The product was subjected to high-speed centrifugation and repeated water washing until it was close to neutral, and was ultrasonically treated for more than 1 hour with ...

Embodiment 3

[0034] 1 g of aramid fiber yarn and 1.5 g of potassium hydroxide were weighed and put into a reactor, DMSO solution was added, and stirred at a temperature of 25° C. for 7 days to obtain an aramid nanofiber solution.

[0035] Weigh 3g of graphite powder and 18g of potassium permanganate into the reactor, slowly add mixed acid (concentrated sulfuric acid: 360mL, concentrated phosphoric acid: 40mL), and stir until uniform. The reaction system was transferred to a water bath, and stirred at a constant temperature of 50° C. for 12 h. Subsequently, the reaction solution was poured onto 400 mL of ice, stirring was continued, and hydrogen peroxide (30 wt.%) was added dropwise until the reaction solution turned bright yellow. The reaction solution was filtered while hot and washed with 1:10 dilute hydrochloric acid. The product was subjected to high-speed centrifugation and repeated water washing until it was close to neutral, and was ultrasonically treated for more than 1 hour with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com