Preparation method of naringin dihydrochlcone

A technology for naringin dihydrochalcone and naringin, which is applied in the field of biological separation and chemical synthesis, can solve the problems of insufficiency, the influence of purifying naringin, and the long process flow, and achieves reduction of mass transfer and heat transfer. resistance, accelerated solvation effect, effect of increasing diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

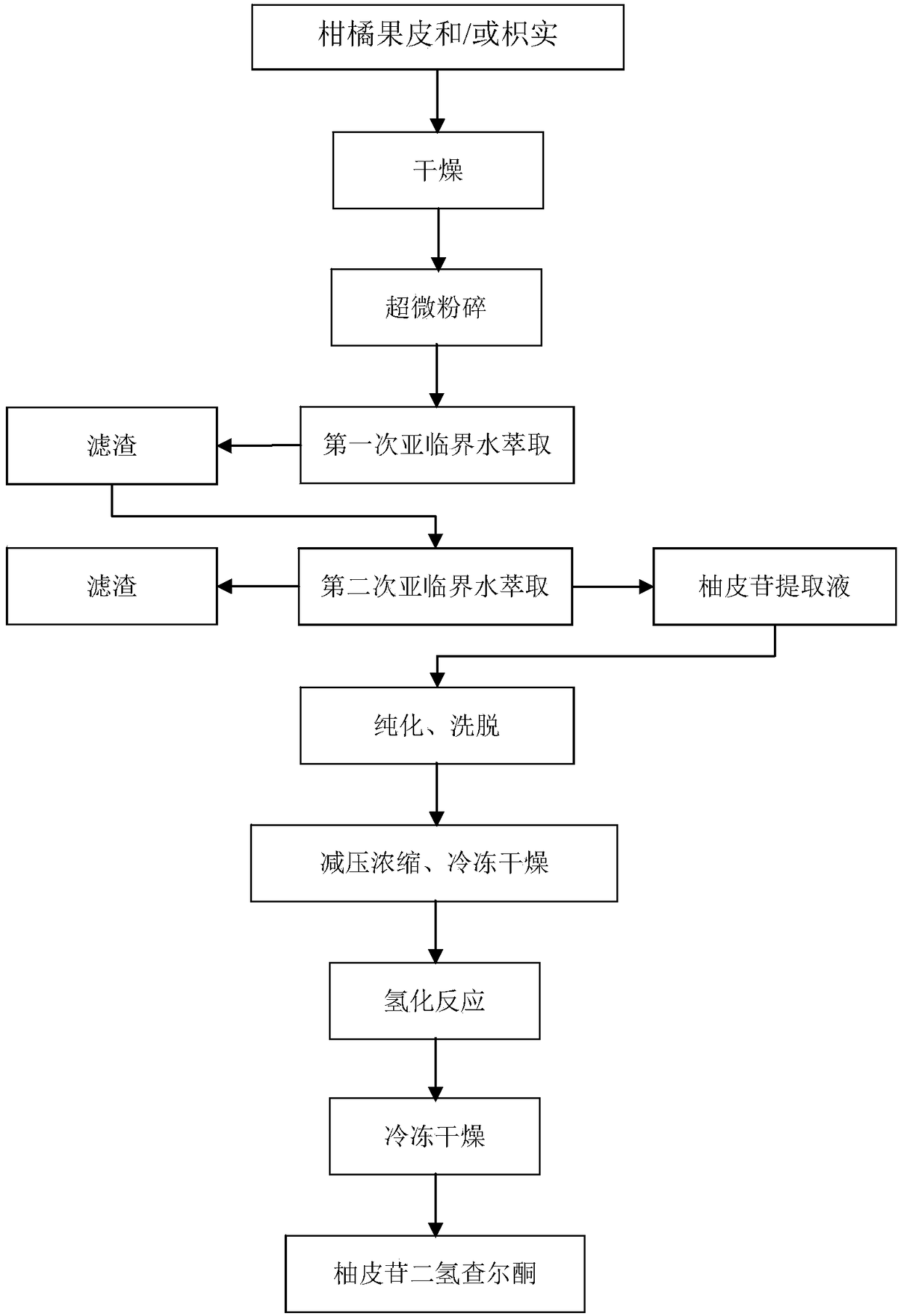

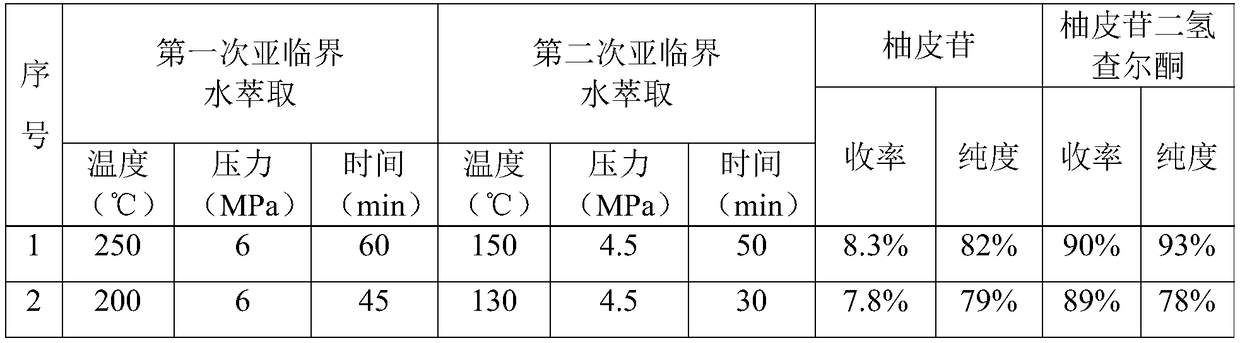

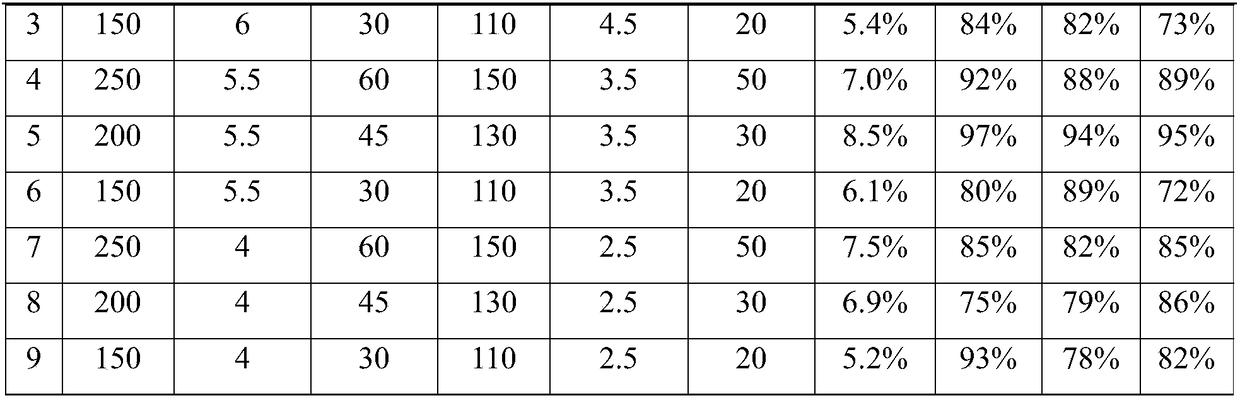

[0033] A kind of preparation method of naringin dihydrochalcone, process flow chart is as follows figure 1 shown, including the following steps:

[0034] (1) Drying and ultrafinely pulverizing the orange peel to obtain citrus peel powder, wherein the particle size of the citrus peel powder is 20 μm.

[0035] (2) Put the citrus peel powder obtained in step (1) into a subcritical extraction kettle, feed high-purity nitrogen, and simultaneously add Deoxygenated distilled water (in this embodiment, deoxygenated distilled water is obtained by injecting high-purity nitrogen gas into the distilled water to remove residual oxygen), the pressure is 6MPa, the temperature is 250 ℃ for the first subcritical water extraction for 60min, cooling , pressure filtration, and discard the filtrate obtained by pressure filtration to obtain a filter residue, which continues to be used for subcritical water extraction.

[0036] (3) According to the mass ratio of gac and filter residue is 5%, the f...

Embodiment 2

[0047] Investigate the effect of different macroporous resins on the extraction effect of naringin:

[0048] Take D101 macroporous resin, D4020 macroporous resin, AB-8 macroporous resin, D130 macroporous resin, HPD450 macroporous resin and D140 macroporous resin, each 2.0g, respectively added to 30mL of Example 1 In the supernatant liquid obtained in step (3), after standing at room temperature and fully adsorbing to reach saturation (24h), filter, measure the content of naringin in the sample liquid before and after adsorption and elute with ethanol solution with a volume concentration of 90% The content of naringin in the back eluent, the results are shown in table 2. Table 2 shows the comparative results of the adsorption capacity and resolution capacity of different macroporous resins.

[0049] Calculate the adsorption rate and desorption rate of limonin by the macroporous resin according to the following formula.

[0050] Adsorption rate (%) = (C 0 -C 1 ) / C 0 ×100

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com