High-toughness anticorrosion CrAlN/Cr2AlC multilayer film coating and preparation method thereof

A multi-layer film and coating technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as insufficient performance, achieve excellent corrosion resistance, prevent the existence of penetrating defects, and avoid elements Effects of Interdiffusion and Structural Transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

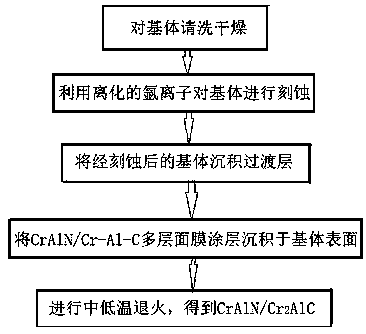

[0031] In this embodiment, a strong, tough and corrosion-resistant CrAlN / Cr 2 The preparation method of AlC multilayer film coating, the steps are as follows:

[0032] (1) Clean and dry the substrate in degreasing agent, alcohol and acetone in turn, and then put it into the vacuum coating chamber;

[0033] (2) Pass argon gas into the vacuum cavity through the anode ion source before the coating, and first utilize ionized argon ions to etch the substrate described in step (1);

[0034] (3) depositing a transition layer on the etched substrate described in step (2);

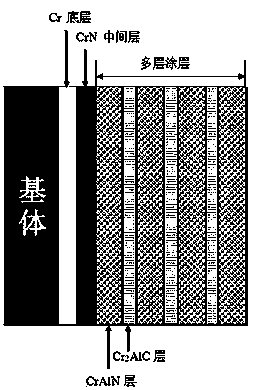

[0035] (4) Use a CrAl target with an atomic ratio of 1:1 as the deposition target, N 2 and hydrocarbon gas as the reaction gas, respectively, in N 2 The CrAlN film is deposited by arc ion plating technology in a mixed atmosphere with Ar gas, and the Cr-Al-C film is deposited by arc ion plating technology in a mixed atmosphere of hydrocarbon gas and Ar gas. The CrAlN / Cr-Al-C multilayer The film coating is deposi...

Embodiment 1

[0039] Put the substrate after cleaning and drying into the vacuum chamber, first pass argon gas 40sccm into the vacuum chamber, set the current of the linear anode ion source to 0.2A, and the negative bias voltage of the substrate to -200V, and use the ionized argon ions to Etch the substrate for 30 minutes; then use the arc ion plating technology to deposit the Ti bottom layer, the target is a Ti target, the arc current is 70A, the Ar gas pressure is 1.0Pa, and the deposition thickness is 250nm; then the reaction gas N 2 , N 2 The pressure is 4Pa, the arc current is 70A, the bias voltage is -100V, and the deposition thickness is 750nm; the fourth step is to deposit CrAlN / Cr-Al-C coating by arc ion plating technology, the target is CrAl composite target, and the current is 70A. When depositing CrAlN single layer, the reaction gas is N 2 , N 2 The pressure is 4Pa, and the reaction gases are Ar and CH when depositing a Cr-Al-C single layer 4 Mixed gas, the cavity pressure is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

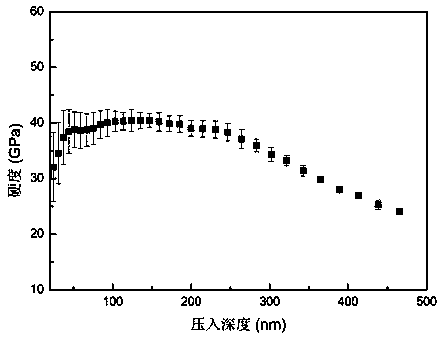

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com