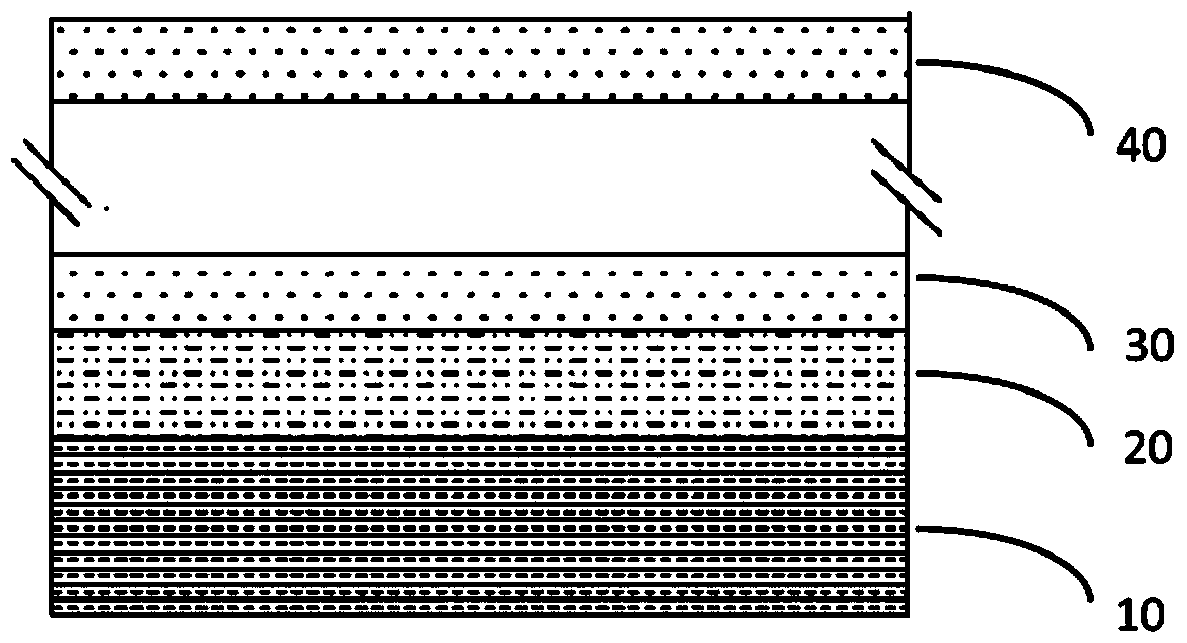

A kind of diamond/diamond-like carbon multilayer composite coating and preparation method thereof

A diamond coating, multi-layer composite technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of coating stress and coating toughness, etc. , Solve the effect of high stress and poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] Specifically, the embodiment of the present invention provides a method for preparing a diamond / diamond-like carbon multilayer composite coating, which includes the following steps:

[0018] S01. Provide a substrate, perform surface pretreatment on the substrate and then load the furnace;

[0019] S02. Under vacuum conditions, pass in methane and perform the first coating process, depositing a diamond coating on the surface of the substrate, wherein the heating temperature of the first coating process is 2000-2500°C, and the substrate temperature is 600-1000°C, the methane concentration is 0.5-3%;

[0020] S03. Under vacuum conditions, adjust the heating temperature and methane concentration to perform a second coating process, deposit a diamond-like coating on the surface of the diamond coating, wherein the heating temperature of the second coating process is 1500-2200°C, The substrate temperature is 400-800°C, and the methane concentration is 2-5%;

[0021] S04. Repeat the f...

Embodiment 1

[0041] In this embodiment 1, a WC-6%Co tool is used as a substrate, and the method for preparing a diamond / diamond-like carbon multilayer composite coating on the substrate includes the following steps:

[0042] S11. Provide a substrate, perform surface pretreatment on the substrate and then load the furnace; specifically,

[0043] S111. Put the WC-Co knife into the acetone solution for ultrasonic cleaning for 30 minutes, and dry it in a constant temperature drying oven at 60°C for 10 minutes;

[0044] S112. Put the cleaned carbide tool into K 3 [Fe(CN) 6 ]+KOH+H 2 O(wt%=1:1:10) alkali mixture ultrasonic for 10min, remove distilled water for cleaning, and then use H 2 SO 4 +H 2 O 2 (vol%=1:10) Soak for 10s, take out distilled water for cleaning, and dry at 60℃ for 20min;

[0045] S113. Put the pretreated tool into a diamond suspension with a mass fraction of 10% by ultrasonic for 30 minutes, take out distilled water for cleaning, and blow dry;

[0046] S114. Heating wire pretreatment: T...

Embodiment 2

[0052] In this embodiment 2, a TiC-Co tool is used as a substrate, and the method for preparing a diamond / diamond-like carbon multilayer composite coating on the substrate includes the following steps:

[0053] S21. Provide a substrate, perform surface pretreatment on the substrate and then load it into a furnace; specifically,

[0054] S211. Put the TiC cutter into the acetone solution for ultrasonic cleaning for 20 minutes, and dry for 10 minutes in a constant temperature drying oven at 70°C;

[0055] S212. Put the cleaned carbide tool into K 3 [Fe(CN) 6 ]+KOH+H 2 O(wt%=1:1:10) Alkali mixture was ultrasonicated for 15min, and the distilled water was removed for cleaning, and then H 2 SO 4 +H 2 O 2 (vol%=1:10) Soak for 15s, take out the distilled water for cleaning, and dry at 60°C at constant temperature for 20min;

[0056] S213. Put the pretreated tool into a diamond suspension with a mass fraction of 8% by ultrasonic for 45 minutes, remove distilled water for cleaning, and blow dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com