Hot spray processing technique for alloy coating of AOF bidirectional protecting oil pump plunger

A technology of alloy coating and processing technology, which is applied in the field of thermal spraying processing technology, can solve the problems of reducing the normal service life of the pump barrel, and achieve the effects of convenient and reasonable control, two-way protection of the pump barrel, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

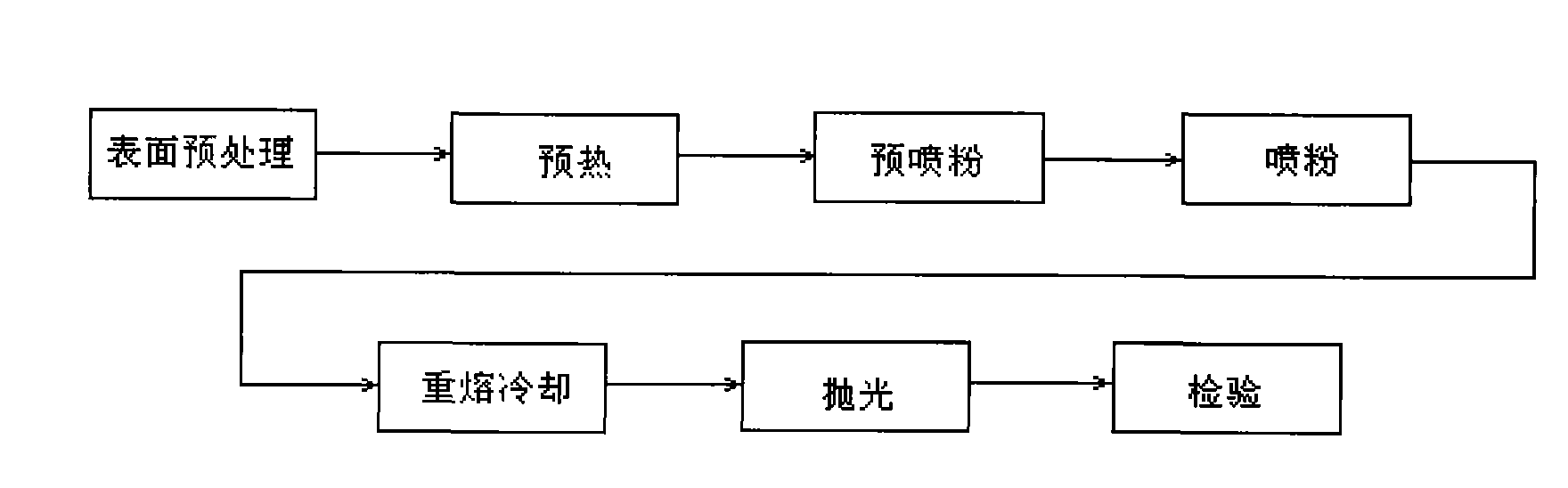

[0012] The alloy coating spraying process on the plunger surface of the AOF two-way protection oil well pump is carried out according to the following procedures:

[0013] 1. Surface pretreatment. The surface of the plunger is roughened with a 100# abrasive belt, and the surface is activated to ensure that the surface is clean and free of oil.

[0014] 2. Preheat. Remove the moisture on the surface of the plunger and increase the temperature of the surface of the plunger, increase the bonding rate of the powder, and avoid the rebound loss caused by excessive powder hitting the cold workpiece. The preheating temperature is generally around 300°C, that is, the color of the plunger surface is almost blue or just blue.

[0015] 3. Pre-spray powder. The plunger surface temperature will eventually rise to 1000°C during the spraying process. When the surface temperature gradually rises above 400°C, the surface metal will be oxidized at a high temperature. In order to prevent thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com