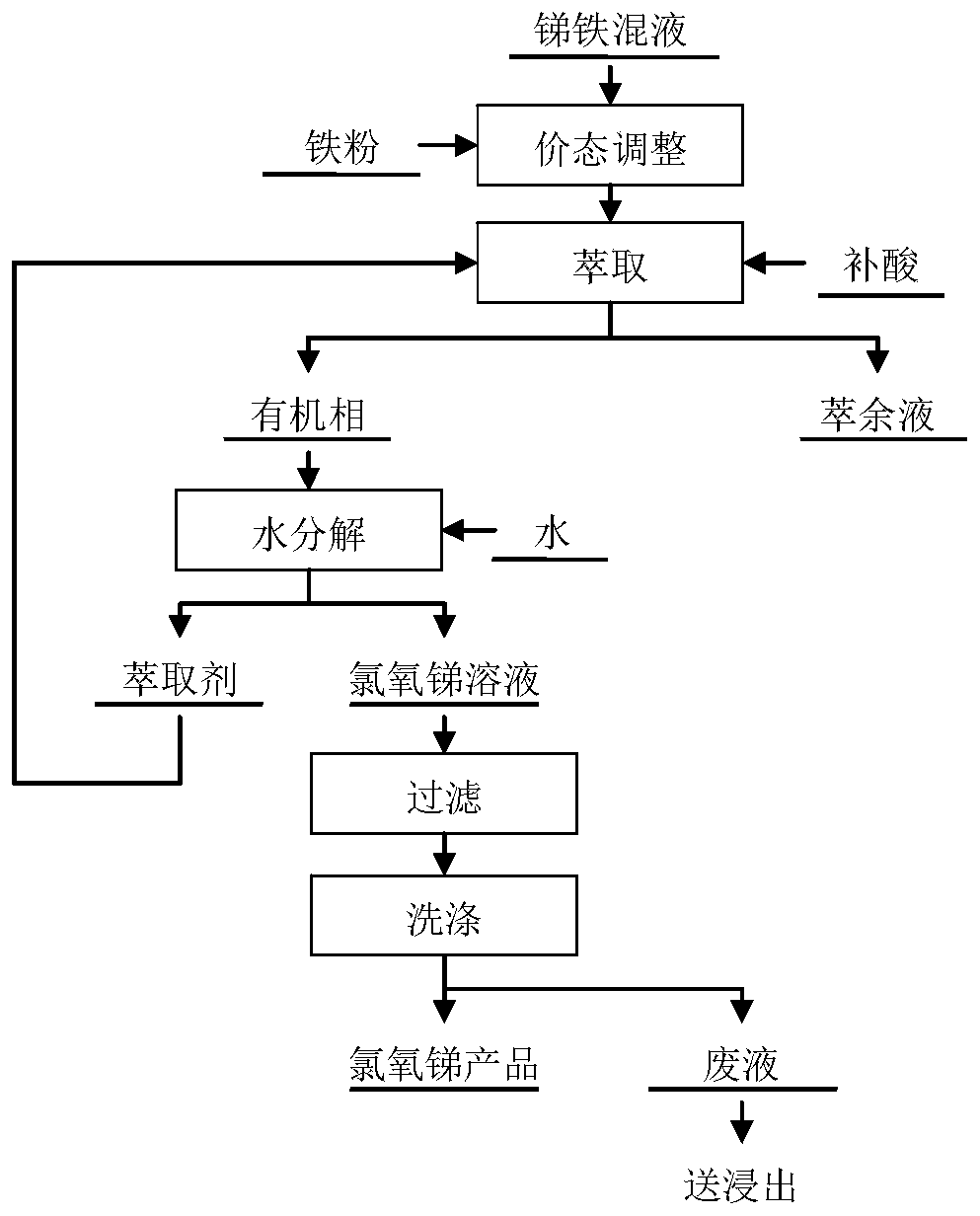

Method for separating antimony and iron by extraction-water decomposition in a mixed solution of antimony and iron

A mixed solution and extraction technology, which is applied in the field of non-ferrous metallurgy, can solve the problems of poor separation of antimony and iron, poor selectivity of P204, poor extraction selectivity, etc., achieve complete separation of antimony and iron, reduce reagents The effect of short consumption and process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

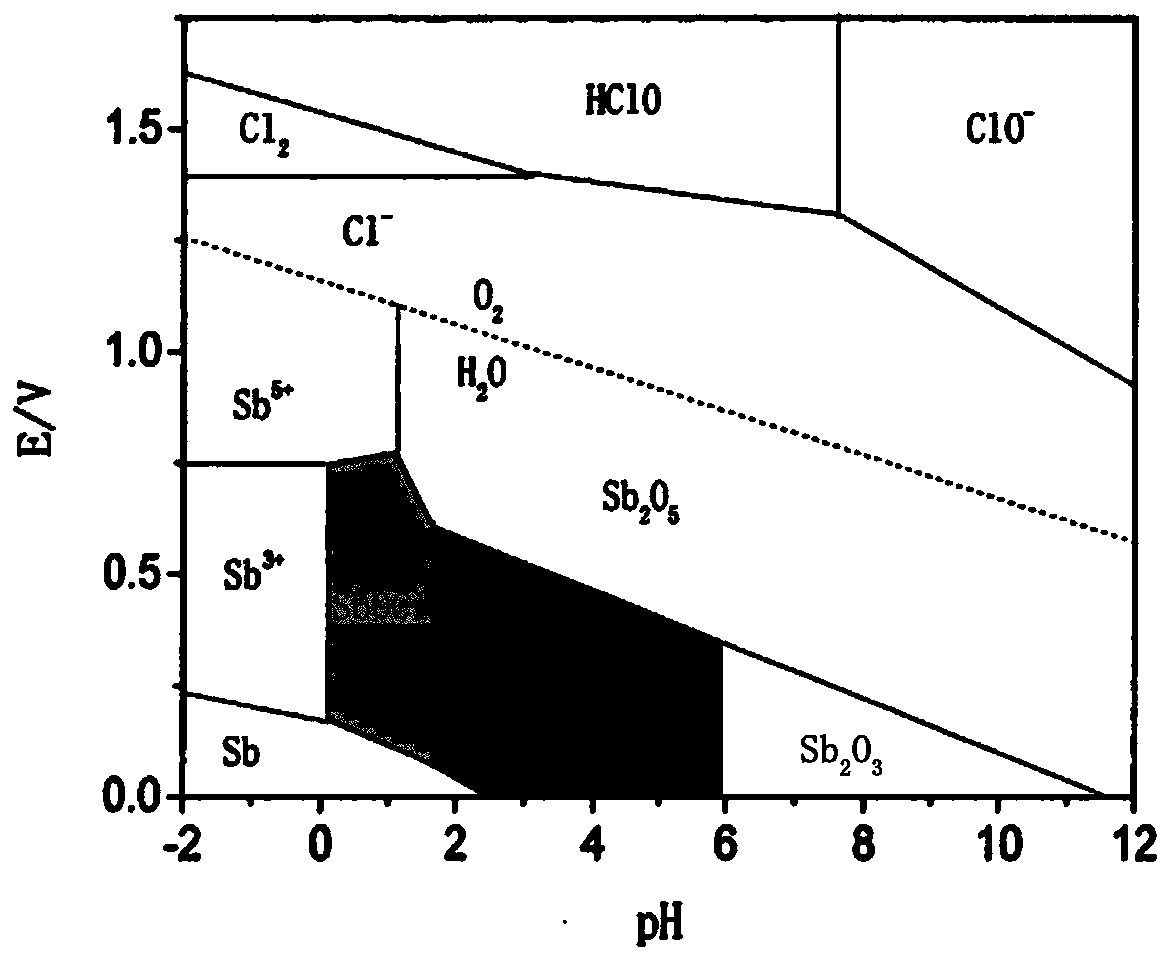

[0042] This example provides a method for separating antimony and iron by extraction-water decomposition in the mixed solution of antimony and iron.

[0043] The composition (g / L) of the antimony-iron mixed solution as the test raw material is: Sb T 35.2, Sb 5+ 1.29 Fe T 21.4 Fe 3+ 2.08. The acidity is 1.3g / L; the iron powder used for valence adjustment is reduced iron powder with a purity of Fe>98%.

[0044] Specific steps are as follows:

[0045] S1. Valence state adjustment: Weigh 500 mL of the antimony-iron mixed solution of the above ingredients, add 1.2 g of reduced iron powder (1.5 times the theoretical amount), and react at 50 ° C for 2 h; separate the supernatant and analyze the Sb in the solution 5+ and Fe 3+ The concentrations are 0.07g / L and 0.14g / L respectively, and the calculated reduction rates of antimony and iron are 94.57% and 93.27% respectively;

[0046] S2. Extraction: Take all the adjustment solution obtained in step S1, add 200mL of organic phase...

Embodiment 2

[0049] This example provides a method for separating antimony and iron by extraction-water decomposition in the mixed solution of antimony and iron.

[0050] The antimony-iron mixed solution and reduced iron powder as test raw materials are the same as in Example 1.

[0051] Specific steps are as follows:

[0052] S1. Valence state adjustment: Weigh 500mL of antimony-iron solution of the above components, add 0.96g of reduced iron powder (1.2 times the theoretical amount), and react at 70°C for 2h; separate the supernatant and analyze the Sb in the solution 5+ and Fe 3+ The concentrations are 0.09g / L and 0.10g / L respectively, and the calculated reduction rates of antimony and iron are 99.74% and 99.53% respectively;

[0053] S2. Extraction: Take all the adjustment solution obtained in step S1, add 180mL organic phase extractant, and its composition is: N235 concentration is 35.0%, TBP concentration is 17.0%, and sec-octanol concentration is 4.0%. Three countercurrent extrac...

Embodiment 3

[0056] This example provides a method for separating antimony and iron by extraction-water decomposition in the mixed solution of antimony and iron.

[0057] The iron antimony solution and reduced iron powder as test raw materials are the same as in Example 1.

[0058] Specific steps are as follows:

[0059] S1. Valence state adjustment: Weigh 1000mL of the antimony-iron solution of the above components, add 1.76g of reduced iron powder (1.1 times the theoretical amount), and react at 70°C for 1h; separate the supernatant and analyze the Sb in the solution 5+ and Fe 3+ The concentrations are 0.11g / L and 0.14g / L respectively, and the calculated reduction rates of antimony and iron are 91.47% and 93.27% respectively;

[0060] S2. Extraction: Take all the adjusted solution obtained in step S1, and add 500 mL of organic phase extractant, which is composed of: N235 concentration of 25.0%, TBP concentration of 15.0%, and sec-octanol concentration of 6.0%. Carry out four counter-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com