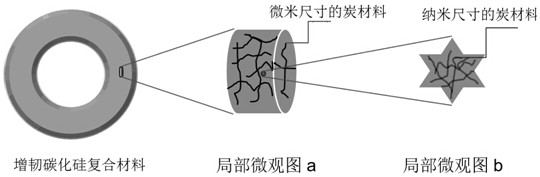

Carbon material 3D toughened silicon carbide composite material and its preparation method and application

A technology for toughening silicon carbide and composite materials, which is applied in the field of carbon material 3D toughening silicon carbide composite materials and its preparation, can solve the problems of large amount of carbon material, poor interface bonding, complicated preparation process, etc., and achieves high bending strength, improved Bending strength, effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] This embodiment provides a carbon material 3D toughened silicon carbide composite material, including 5wt% of carbon fibers with a length of 1.0 mm, 3wt% of carbon nanotubes and 92wt% of silicon carbide (D50=0.6 um).

[0024] The preparation method of the above carbon material 3D toughened silicon carbide composite material is as follows:

[0025] Take 5 parts by mass of carbon fiber pretreated by wetting, 3 parts of carbon nanotubes and 92 parts of silicon carbide micropowder through wetting pretreatment and add them to the ball mill tank, and add silicon carbide grinding balls according to the ball-to-material ratio of 4:1, and the material The ratio accounts for 2 / 3 of the volume of the ball milling tank, the ball milling rate is 400 r / min, and the ball milling time is 0.5 h. After the ball milling, the carbon material 3D toughened silicon carbide composite material is obtained.

[0026] The method for the above-mentioned wetting pretreatment of carbon fibers and car...

Embodiment approach 2

[0030] This embodiment provides a carbon material 3D toughened silicon carbide composite material, which contains 1 wt% of carbon fibers with a length of 0.5 mm, 0.5 wt% of carbon nanotubes and 98.5 wt% of silicon carbide (D50=1.2 um).

[0031] The preparation method of the above carbon material 3D toughened silicon carbide composite material is as follows:

[0032] Take 1 mass part of carbon fiber pretreated by wetting, 0.5 part of carbon nanotubes and 98.5 parts of silicon carbide micropowder through wetting pretreatment and add them to the ball mill jar, and add silicon carbide grinding balls according to the ball-to-material ratio of 2:1 to Absolute ethanol was used as the dispersion medium, the material ratio accounted for 2 / 3 of the volume of the ball milling tank, the ball milling speed was 500 r / min, and the ball milling time was 6 h. After the ball milling, a carbon material 3D toughened silicon carbide composite material was obtained.

[0033] The method for the abov...

Embodiment approach 3

[0037] This embodiment provides a carbon material 3D toughened silicon carbide composite material, including 3wt% of carbon nanotubes with a length of 100 um, 10wt% of mesoporous porous carbon, and 87wt% of silicon carbide (D50=0.9 um).

[0038] The preparation method of the above carbon material 3D toughened silicon carbide composite material is as follows:

[0039]Take 3 parts by mass of carbon nanotubes pretreated by wetting, 10 parts of porous carbon mainly mesoporous and pretreated by wetting, and 87 parts of silicon carbide micropowder into a ball mill tank, and add carbonization at a ball-to-material ratio of 8:1. Silicon grinding balls, using absolute ethanol as the dispersion medium, the material ratio accounts for 2 / 5 of the volume of the ball milling tank, the ball milling rate is 400 r / min, the ball milling time is 12 h, and the carbon material 3D toughened silicon carbide composite material is obtained after ball milling .

[0040] The method for the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com