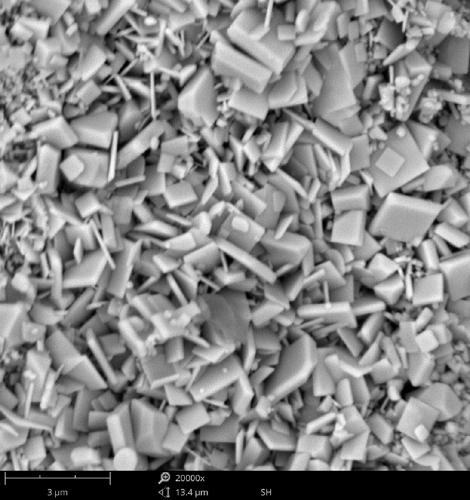

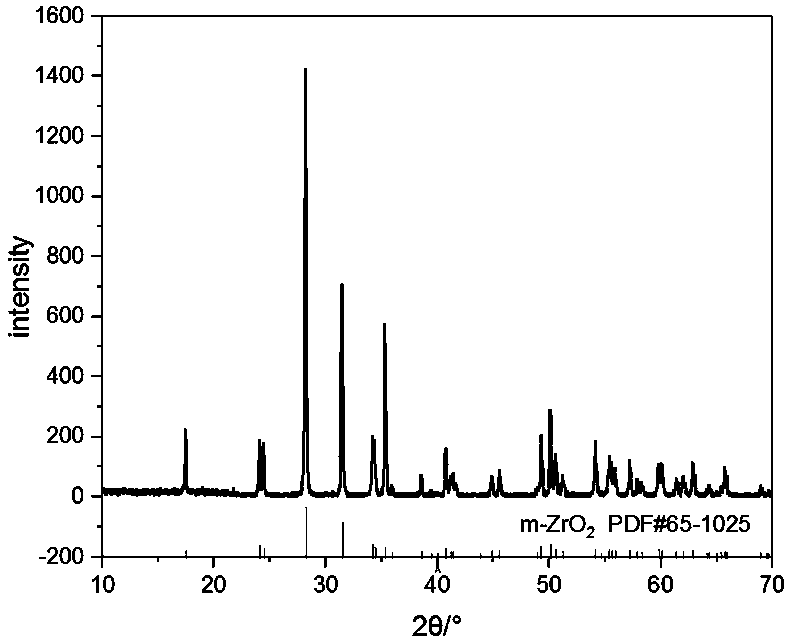

A kind of preparation method of rectangular flaky monoclinic zirconia

A zirconium oxide and flake technology, applied in the field of new inorganic materials, can solve the problems of long period, small parallel dimension of layers, irregular shape and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Zirconium oxychloride is used as the reaction precursor, sodium chloride is used as the molten salt, and sodium fluoride is used as the molten salt additive. First, zirconium oxychloride was heat-treated at 100°C for 22 h to obtain a calcined product, and then weighed 2 g of the calcined product, 2 g of sodium chloride and 0.2 g of sodium fluoride, with a mass ratio of 10:10:1, Grind after mixing. The ground mixture was placed in a corundum crucible and heated in a resistance furnace. The temperature was raised to 400°C at 5°C / min and kept for 20 minutes, and then continued to rise to 800°C for 5 hours. After it was cooled to room temperature, the obtained calcined product was washed three times with deionized water, then washed once with absolute ethanol, and finally dried at 70 °C for 6 h to obtain rectangular flaky monoclinic zirconia.

Embodiment 2

[0022] Zirconium oxychloride is used as precursor, sodium chloride is used as molten salt, and sodium fluoride is used as molten salt additive. First, zirconium oxychloride was heat-treated at 110°C for 20 h to obtain a calcined product, and then weighed 2 g of the calcined product, 1 g of sodium chloride and 0.2 g of sodium fluoride, with a mass ratio of 10:5:1, Grind after mixing. The ground mixture was placed in a corundum crucible and heated in a resistance furnace. The temperature was raised to 450°C at 5°C / min and kept for 15 minutes, and then continued to rise to 850°C for 5 hours. After it was cooled to room temperature, the obtained calcined product was washed three times with deionized water, then washed once with absolute ethanol, and finally dried at 70 °C for 6 h to obtain rectangular flaky monoclinic zirconia.

Embodiment 3

[0024] Zirconium oxychloride is used as precursor, sodium chloride is used as molten salt, and sodium fluoride is used as molten salt additive. First, zirconium oxychloride was heat-treated at 120°C for 18 h to obtain a calcined product, and then weighed 2 g of the calcined product, 2 g of sodium chloride and 0.4 g of sodium fluoride, with a mass ratio of 10:10:2, Grind after mixing. The ground mixture was placed in a corundum crucible and heated in a resistance furnace. The temperature was raised to 500°C at a rate of 5°C / min and kept for 10 minutes, and then continued to rise to 900°C for 3 hours. After it was cooled to room temperature, the obtained calcined product was washed three times with deionized water, then washed once with absolute ethanol, and finally dried at 70 °C for 6 h to obtain rectangular flaky monoclinic zirconia.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com