Two-component fabric with color spinning style and processing method thereof

A processing method and two-component technology, which can be used in textiles, textiles, papermaking, fabrics, etc., can solve the problems of inconspicuous color layers and unsatisfactory color spinning effects, and achieve the effect of rich color layers and increased randomness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

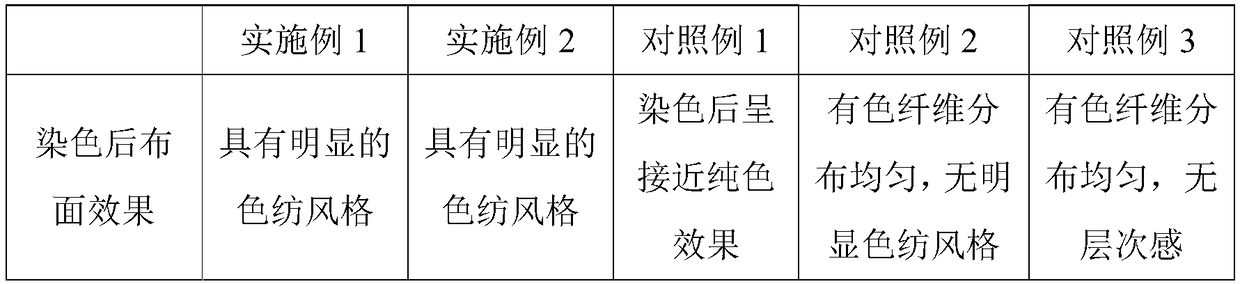

Examples

Embodiment 1

[0022] Size: 106.5” / 32s*32s / 133*72, weave is 3 / 1 left twill.

[0023] The first fiber is viscose fiber, and the second fiber is polyester fiber. The blend ratio of warp and weft is viscose / polyester 80 / 20.

[0024] The production process specifically includes the following procedures: fiber selection - pretreatment - viscose fiber opening and cleaning, carding - polyester fiber opening and cleaning, carding - pre-drawing - drawing - eddy current spinning - warping - sizing - Weaving - pre-treatment of gray fabric cold stacking - pre-setting - disperse dyeing - soft setting - pre-shrinking.

[0025] In the pretreatment process, the viscose fiber is cut to a length of 38mm, and the polyester fiber has two lengths after cutting: the length of the longer fiber is 50mm, and the length of the shorter fiber is 30mm, and the polyester fiber is sprayed with antistatic agent .

[0026] The viscose fiber opening and cleaning and carding process and the polyester fiber opening and clea...

Embodiment 2

[0030] Specification: 106” / 40s*40s / 144*75, the weave is 2 / 2 left twill weave.

[0031] The first fiber is cotton fiber, and the second fiber is polyester fiber. The blend ratio of warp and weft is cotton / polyester 80 / 20.

[0032] The production process specifically includes the following procedures: fiber selection - pretreatment - cotton fiber opening and cleaning, carding - combing - polyester fiber opening and cleaning, carding - pre-drawing - drawing - vortex spinning - warping - Sizing - weaving - gray fabric descouring and bleaching - presetting - light sanding - disperse dyeing - soft setting - preshrinking.

[0033] In the pretreatment process, there are two lengths of cut polyester fiber: the length of the longer fiber is 50 mm, and the length of the shorter fiber is 30 mm, and the polyester fiber is sprayed with an antistatic agent. The first fiber is cotton fiber, which is a natural fiber and does not need to be cut.

[0034] Cotton fiber opening and cleaning, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com