High-strength artificial board and manufacturing technology thereof

A wood-based panel, high-strength technology, applied in the field of high-strength wood-based panel and its manufacturing process, can solve the problems of wood-plastic composite materials such as poor mechanical properties, low impact resistance, poor interface compatibility, etc., achieve low cost, improve processing Performance and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

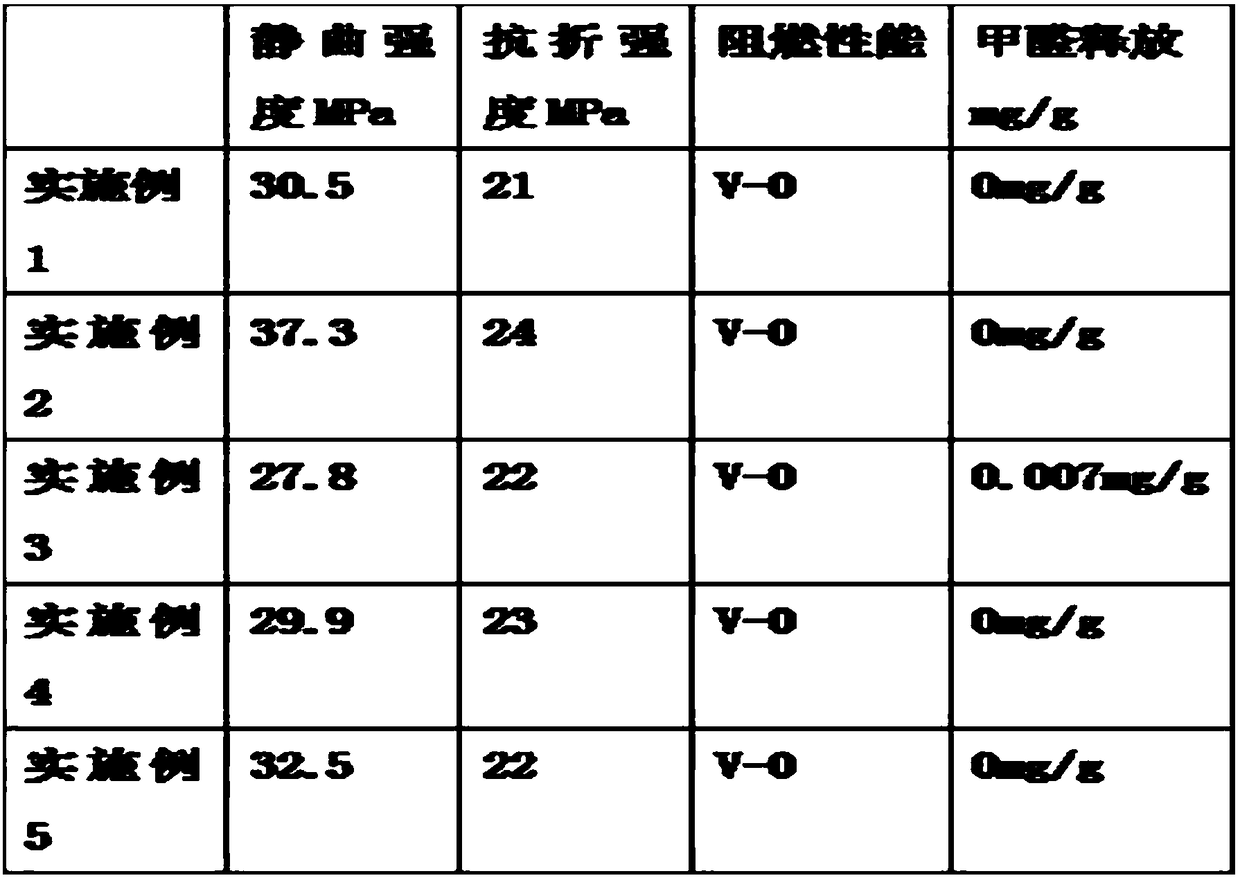

Examples

Embodiment 1

[0027] A high-strength wood-based panel, which comprises the following components by weight: 30 parts of Chinese fir powder, 20 parts of sisal slag powder, 20 parts of polyethylene, 5 parts of urea-formaldehyde resin adhesive, 3 parts of flame retardant, 3 parts of insect repellent, acrylonitrile 2 parts, 1 part of magnesium titanate, 0.8 part of formaldehyde-removing traditional Chinese medicine powder.

[0028] A preparation method for high-strength wood-based panels, comprising the steps of:

[0029] (1) Crush magnesium titanate and calcium titanate into powder, mix with Chinese fir powder, sisal slag powder and formaldehyde-removing traditional Chinese medicine powder, then stir for 12 minutes at a speed of 300r / min, and set the temperature at 40°C;

[0030] (2) Pour the remaining materials obtained from step (1) into the twin-screw extruder, and set the extrusion temperature: 90°C for zone I, 110°C for zone II, 140°C for zone III, and 150°C for zone IV. The temperature i...

Embodiment 2

[0038] A high-strength wood-based panel, which comprises the following components by weight: 50 parts of fir powder, 30 parts of sisal slag powder, 30 parts of polyethylene, 10 parts of urea-formaldehyde resin adhesive, 5 parts of flame retardant, 6 parts of insect repellent, acrylonitrile 4 parts, 3 parts of magnesium titanate, 1 part of formaldehyde-removing traditional Chinese medicine powder.

[0039] A preparation method for high-strength wood-based panels, comprising the steps of:

[0040] (1) Crush magnesium titanate and calcium titanate into powder, mix with fir powder, sisal residue powder and formaldehyde-removing traditional Chinese medicine powder, then stir for 18 minutes at a speed of 500r / min, and set the temperature at 60°C;

[0041] (2) Pour the remaining materials obtained in step (1) into the twin-screw extruder, and set the extrusion temperature: 100°C for zone I, 120°C for zone II, 150°C for zone III, and 160°C for zone IV. The temperature is 180°C, the h...

Embodiment 3

[0049] A high-strength wood-based panel, which comprises the following components by weight: 35 parts of fir powder, 24 parts of sisal slag powder, 24 parts of polyethylene, 6 parts of urea-formaldehyde resin adhesive, 4 parts of flame retardant, 4 parts of insect repellent, acrylonitrile 3 parts, magnesium titanate 2 parts, formaldehyde-removing traditional Chinese medicine powder 0.9 parts.

[0050] A preparation method for high-strength wood-based panels, comprising the steps of:

[0051] (1) Grind magnesium titanate and calcium titanate into powder, mix with fir powder, sisal residue powder and formaldehyde-removing traditional Chinese medicine powder, then stir for 14 minutes at a speed of 350r / min, and set the temperature at 45°C;

[0052] (2) Pour the remaining materials obtained in step (1) into the twin-screw extruder, set the extrusion temperature: 93°C for zone I, 114°C for zone II, 144°C for zone III, 154°C for zone IV, and the extrusion head The temperature is 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com