Self support high density metal oxide/nitrogen doped graphene composite electrode, and preparation method and application thereof

A technology of nitrogen-doped graphene and composite electrodes, which is applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve the problems of poor cycle performance, easy falling off of pole pieces, and easy crushing, so as to maintain stability and solve problems easily. The effect of shedding and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation

[0035] S1. Under the condition of magnetic stirring, add 0.5mg ml to 200ml -1 Add 8ml of cyanamide aqueous solution dropwise to the graphene oxide aqueous solution. After the dispersion is uniform, transfer it to a 250ml three-neck flask, react in a water bath at 90°C for 24 hours, and continue mechanical stirring, then vacuum filter and dry to obtain nitrogen-doped graphene. ;

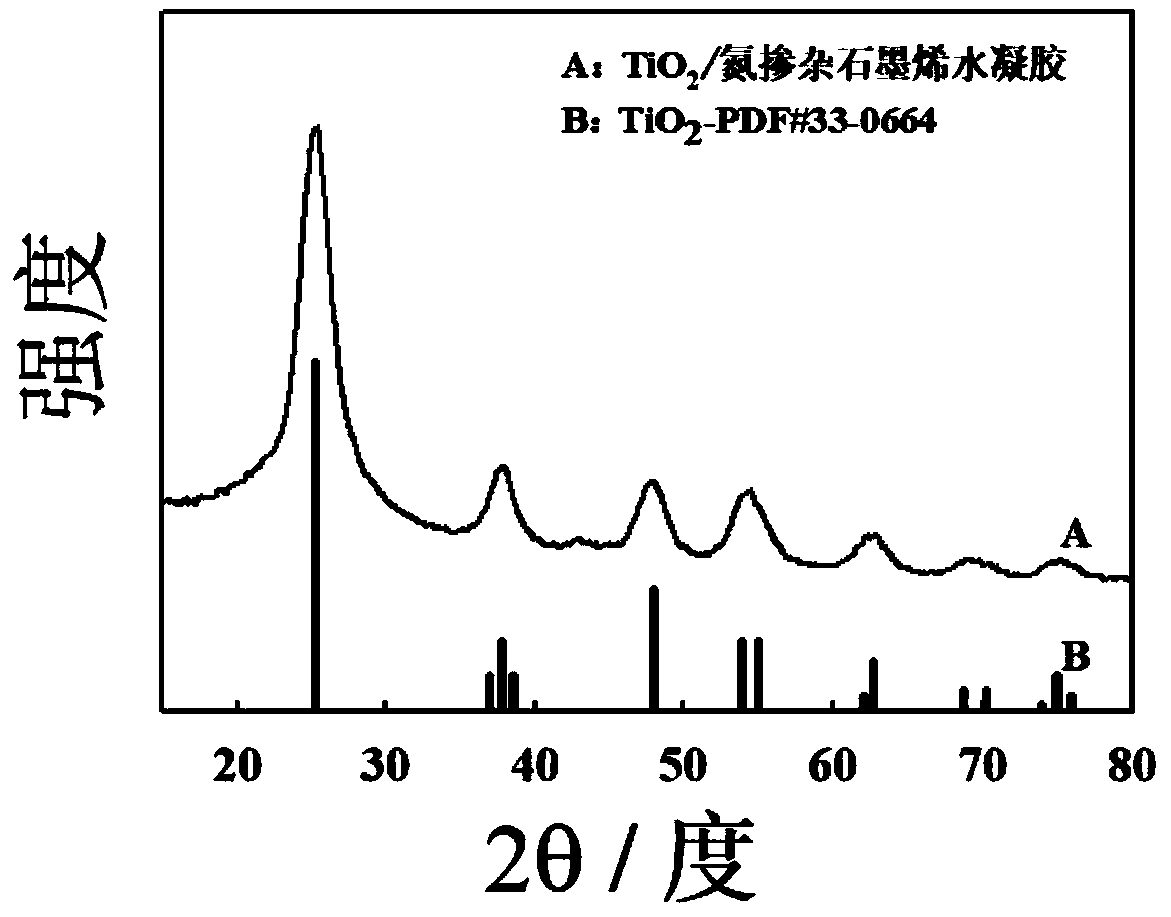

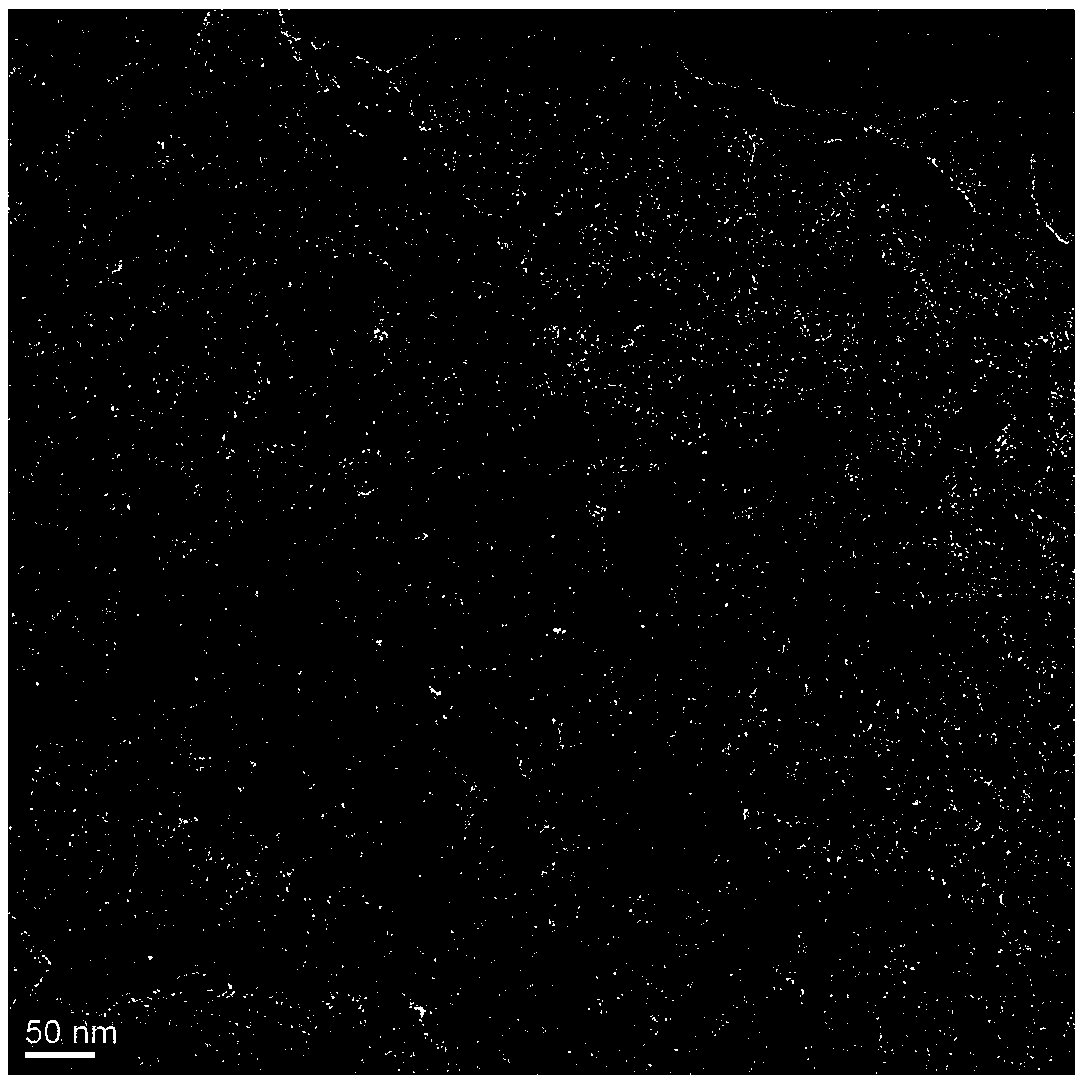

[0036] S2. Weigh 30mg of nitrogen-doped graphene and stir or ultrasonically disperse evenly in 185ml of absolute ethanol, then add 3.3ml of 0.55mol l -1 Dissolved TiCl 4 Add 4ml of deionized water dropwise, stir for a period of time, and then conduct a hydrothermal reaction in a 200ml hydrothermal kettle at 120°C for 2 hours, then filter, dry, and wash to obtain TiO 2 / Nitrogen-doped graphene powder material;

[0037] S3. 28ml 4.5mg ml -1 Graphene oxide is dispersed in 25ml of aqueous solution, weigh 714mg of the product in S2 and disperse in 20ml of absolute ethanol solut...

Embodiment 2

[0042] 1. Preparation

[0043] S1. Under the condition of magnetic stirring, add 8ml of triethylamine aqueous solution dropwise to 100mg of graphene oxide aqueous solution. After the dispersion is uniform, transfer it to a 250ml three-necked flask, react in a water bath at 110°C for 6h, and continue to stir mechanically, and then filter through vacuum , dry to obtain nitrogen-doped graphene;

[0044] S2. Weigh 30mg of nitrogen-doped graphene and stir or ultrasonically disperse evenly in 185ml of acetone, then add 4ml of 0.6mol l -1 Dissolved Fe(NO 3 ) 3 Add 4ml of deionized water dropwise, and after stirring for a period of time, react in a 200ml hydrothermal kettle at 130°C for 4 hours, then filter, dry and wash to obtain Fe 2 o 3 / Nitrogen-doped graphene powder material;

[0045] S3. Mix 30ml with 4.2mg ml -1 Graphene oxide is dispersed in 25ml of aqueous solution, weigh 504mg of the product in S2 and disperse it in 20ml of absolute ethanol solution, then add the latte...

Embodiment 3

[0050] 1. Preparation

[0051] S1. Under the condition of magnetic stirring, add 4 g of urea aqueous solution dropwise to 100 mg of graphene oxide aqueous solution. After the dispersion is uniform, transfer it to a 250ml three-necked flask, react in a water bath at 95°C for 28 hours, and continue to stir mechanically, then vacuum filter and dry , to obtain nitrogen-doped graphene;

[0052] S2. Weigh 30mg of nitrogen-doped graphene and stir or ultrasonically disperse evenly in 185ml of isopropanol, then add dropwise 2.6ml of 0.75mol l -1 Dissolved with Sn(SO 4 ) 2 Then add 4ml of deionized water dropwise, stir for a period of time, and then conduct a hydrothermal reaction at 110°C in a 200ml hydrothermal kettle for 5h, then filter, dry, and wash to obtain SnO 2 / Nitrogen-doped graphene powder material;

[0053] S3. Mix 20ml with 4.5mg ml -1 Graphene oxide is dispersed in 25ml of aqueous solution, weigh 390mg of the product in S2 and disperse in 20ml of absolute ethanol sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com