Steelmaking equipment and smelting method for steelmaking by steel scrap

A smelting method and technology for scrap steel, applied in the smelting field of steel making with scrap steel, can solve the problems of high consumption of steel materials, large power grid impact, low thermal efficiency, etc., and achieve the effect of saving electricity consumption per ton of steel, small power grid impact, and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

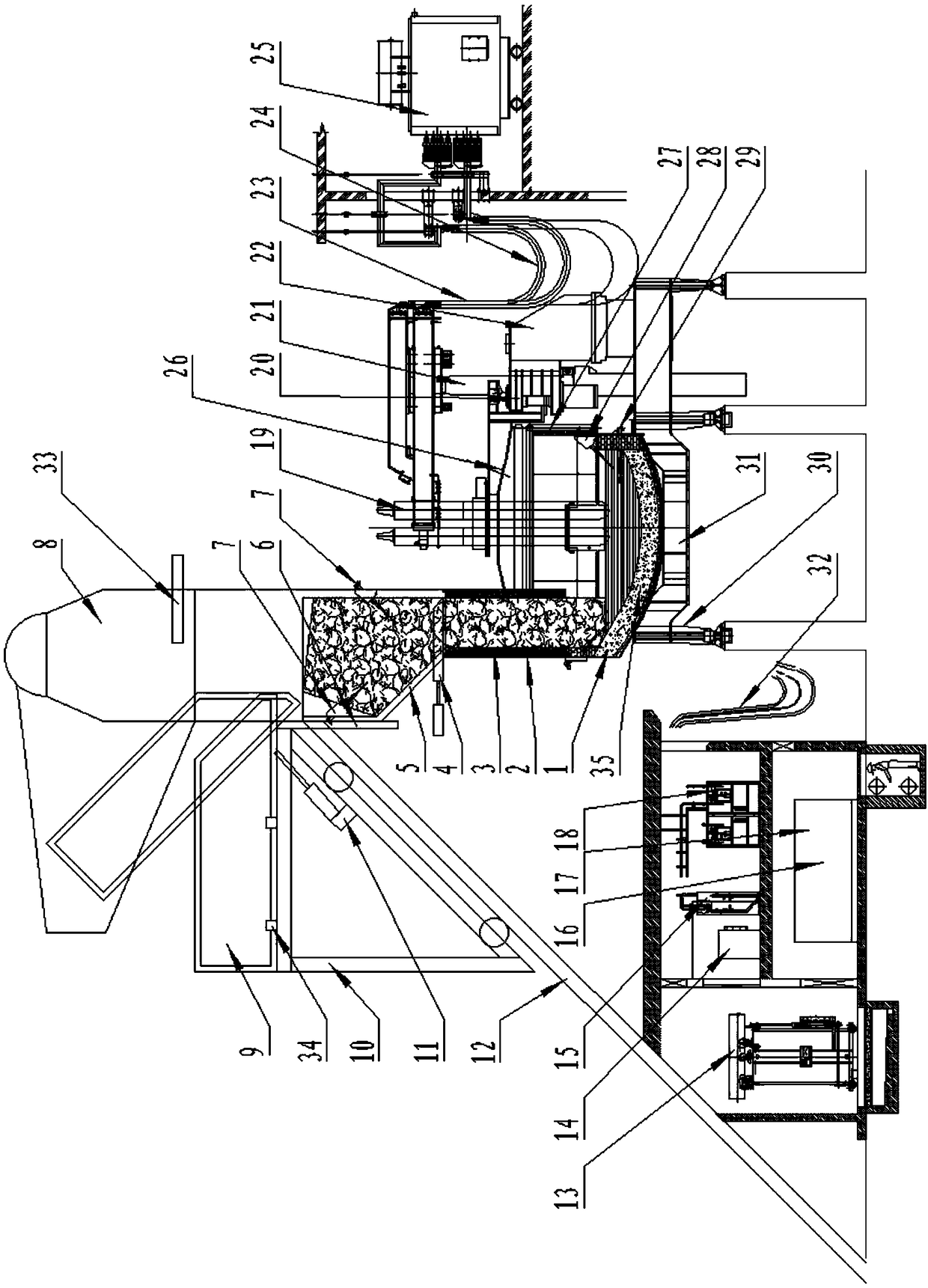

[0032] A steel-making equipment for making steel with scrap steel includes an induction heating shaft 2, an electric arc furnace 1 and a scrap preheating chamber 5. The induction heating shaft 2 is a cylindrical structure with both upper and lower ends open, and the upper end of the induction heating shaft 2 is an induction The entrance of the heating shaft 2, and the lower end of the induction heating shaft 2 is the exit of the induction heating shaft 2. The induction heating shaft 2 can perform electromagnetic induction heating on the charge in the induction heating shaft 2; the electric arc furnace 1 includes a furnace cover 26 and a furnace set up and down The furnace body contains an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com