A kind of high thermal conductivity silicone grease interface material and preparation method thereof

An interface material and high thermal conductivity technology, which is applied in the field of thermal conductivity materials, can solve the problems of not meeting the thermal control requirements of high-density stand-alone machines, the separation of base materials and thermal conductivity fillers, and the ineffective conduction of heat, so as to inhibit the possibility of degradation and reduce the content , Reduce the effect of oil separation and evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

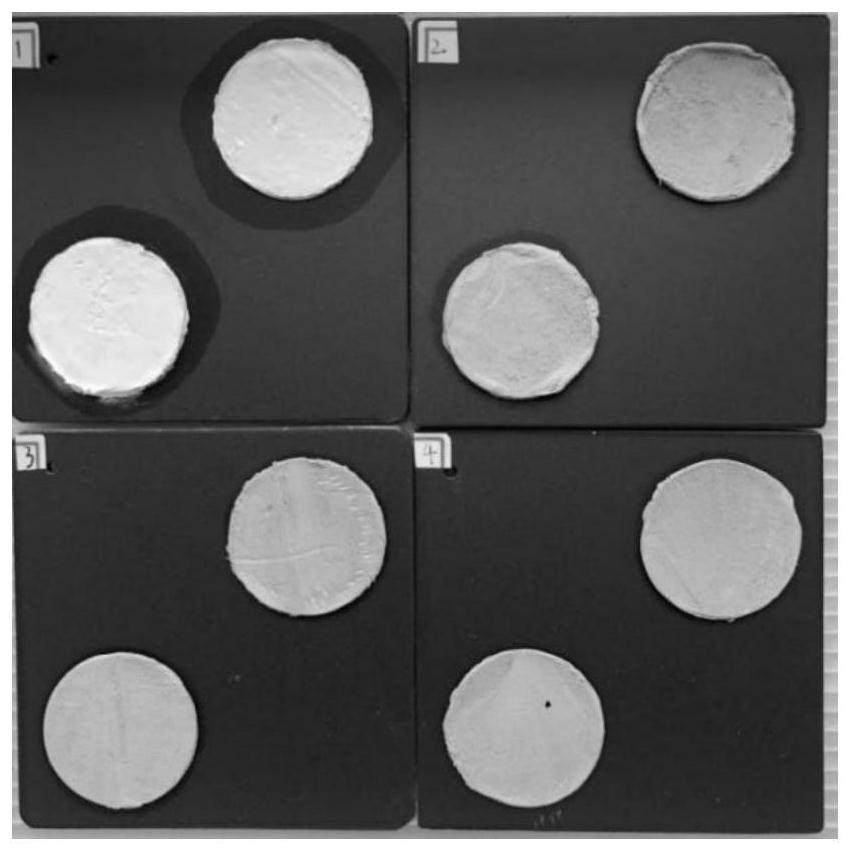

[0039] Example 1: High thermal conductivity silicone grease GDZ-1

[0040] ① Coat the thermally conductive filler aluminum powder and silver powder with a layer of silane coupling agent: surface-treat thermally conductive aluminum powder and silver powder with different particle sizes, and silane coupling equivalent to 1% to 2% of the mass of the filler aluminum powder and silver powder Dissolve the agent KH570 in absolute ethanol, stir to dissolve it, weigh the preset mass of filler aluminum powder and silver powder, put them into the silane coupling agent solution respectively, use the powder coating equipment, stir at 60°C for 3 hours, take it out and let it stand , after suction filtration, take the filter and wash with absolute ethanol for 3 times, and dry at 80°C for 24 hours to obtain thermally conductive aluminum powder and silver powder coated with a layer of silane coupling agent on the surface;

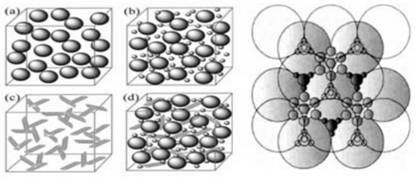

[0041] ② Match the particle size of the heat-conducting aluminum powde...

Embodiment 2~6

[0044]Examples 2~6: High thermal conductivity silicone grease GDZ-2~GDZ-6

[0045] For the experimental procedures of Examples 2-6, refer to Example 1. In terms of parts by weight, refer to the composition of the high-thermal-conductivity silicone grease interface material in Table 1 to prepare Examples 2-6 of the high-thermal-conductivity silicone grease interface material.

[0046] Table 1 Composition of High Thermal Conductivity Silicone Grease Interface Materials in Examples 2-6

[0047]

[0048] Note: The description of raw material components is as follows:

[0049] (B) Silicone oil

[0050] A1: Simethicone

[0051] A2: Methylphenyl silicone oil

[0052] A3: Hydroxyl-terminated simethicone

[0053] (C) Silane coupling agent

[0054] B1: KH550

[0055] B2: KH560

[0056] B3: KH570

[0057] (D) Thermally conductive filler

[0058] C1: Aluminum powder (spherical, average particle size 30um)

[0059] C2: Aluminum powder (spherical, average particle size 15um)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com