A kind of plasmon resonance electromagnetic enhanced bimetallic-dielectric heterogeneous material and its preparation and application

A plasmon resonance, heterogeneous material technology, applied in metal material coating process, metal processing equipment, transportation and packaging, etc., to achieve the effect of easy industrial application and popularization, cheap and easily available raw materials, and significant microwave electromagnetic enhancement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 2.67g (225mM) CoCl 2 ·6H 2 O and 2g (1M) NaOH were dissolved in 50 mL distilled water. Then 15mL of 85% hydrazine hydrate (N 2 H 4 ·H 2 O) Add to the solution as a reducing agent. After stirring vigorously for 20 minutes, it was transferred to a stainless steel autoclave, kept at 120°C for 4 hours, and then cooled to room temperature. The final product collected by the magnet was washed three times with distilled water and ethanol, and dried under vacuum at 35°C for 12 hours to obtain a precursor of graded flower-like Co.

[0029] Add 3mL Fe(CO) to the Ark 5 Place it at the air inlet, divide 0.5 g of flower-shaped Co into two parts and spread them on the bottom of the ark, and place the two arks in the heating zone of the tube furnace. Incubate at 250℃ for 2 hours under the protection of argon, heating rate 5℃·min -1 . Finally, the Co-Fe heterostructure is obtained, which is a plasmon resonance electromagnetic enhanced bimetal material.

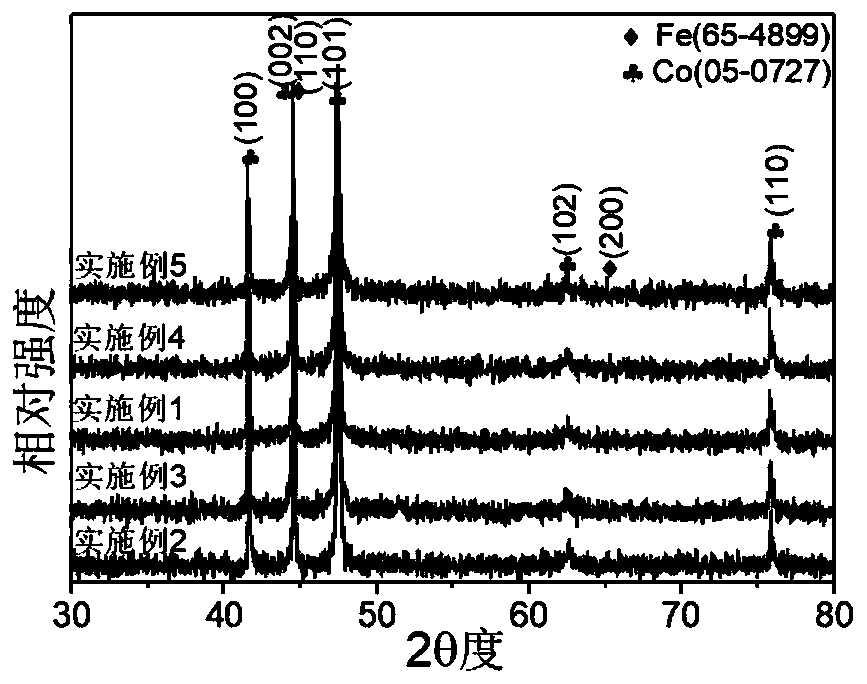

[0030] The phase of the plasmon r...

Embodiment 2

[0032] 2.67g (225mM) CoCl 2 ·6H 2 O and 2g (1M) NaOH were dissolved in 50 mL distilled water. Subsequently, 15 mL of 85% hydrazine hydrate (N 2 H 4 ·H 2 O) Add to the solution as a reducing agent. Stir vigorously, then transfer to a stainless steel autoclave at 120°C for 4 hours, and then cool to room temperature. The final product was collected by the magnet and washed several times with distilled water and ethanol, and then vacuum dried at 35°C for 12 hours. A precursor of graded flower-shaped Co is obtained.

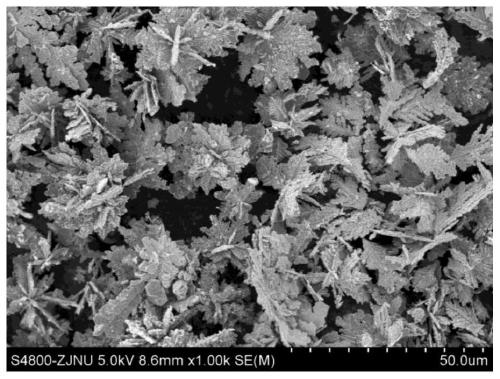

[0033] The morphology observed under the scanning electron microscope is like Picture 10 As shown, the product is flower-like Co, and the flower-like Co is 6.96-14.53 μm long. Its magnetostatic properties such as Image 6 As shown, the saturation magnetization is 154.31emu·g -1 , The coercivity is 215.56G; its electromagnetic parameters such as Figure 7~8 As shown, the real part and imaginary part of the dielectric constant are 9.2~9.6 and -0.005~0.06 respectively in...

Embodiment 3

[0035] Same steps as in Example 1, but add 1mL Fe(CO) 5 .

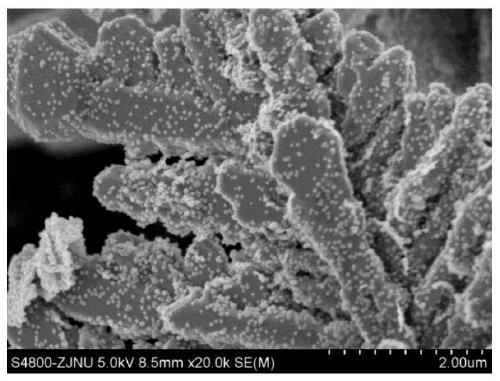

[0036] The morphology observed under the scanning electron microscope is like Picture 12 As shown, the product is a Co-Fe heterostructure, the flower-like Co is 7.85-16.33 μm long, and Fe nanocrystals are evenly distributed on the surface. Its energy spectrum is like Figure 5 As shown, the cobalt-iron atomic ratio is 21.08; the C atomic percentage is 11.0%. Its magnetostatic properties such as Image 6 As shown, the saturation magnetization is 149.09emu·g -1 , The coercivity is 213.82G. Its electromagnetic parameters such as Figure 7~8 As shown, in the frequency range of 2-18 GHz, the real and imaginary parts of the dielectric constant are increased by 0.95-2 and 40-125 times relative to the graded flower precursor Co, respectively, and the real and imaginary parts of the permeability are relative to the graded flower The shape precursor Co increased by 0.4-1 and 1.5-8.8 times, respectively. Its two-dimensional refl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com