A kind of electromagnetic reinforced carbon magnetic composite material and its preparation method and application

A composite material, electromagnetic technology, applied in the fields of carbon compounds, chemical instruments and methods, nanotechnology for materials and surface science, etc. Novel, easy composition, and novel effect of formation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add expanded graphite (500mg), PVP (2g), and water (150mL) obtained by expanding at 700°C to a 250mL beaker and stir for 12 hours to obtain modified expanded graphite, then mix the modified expanded graphite with iron glycolate Nanosheets (200mg) and water (100mL) were mixed and stirred in a beaker for 2h. The product obtained after suction filtration was baked in a vacuum oven at 60°C for 5 hours, and finally the sample was placed in N 2 Sintering at 400°C for 2 hours under protection to obtain an electromagnetically reinforced carbon-magnetic composite material.

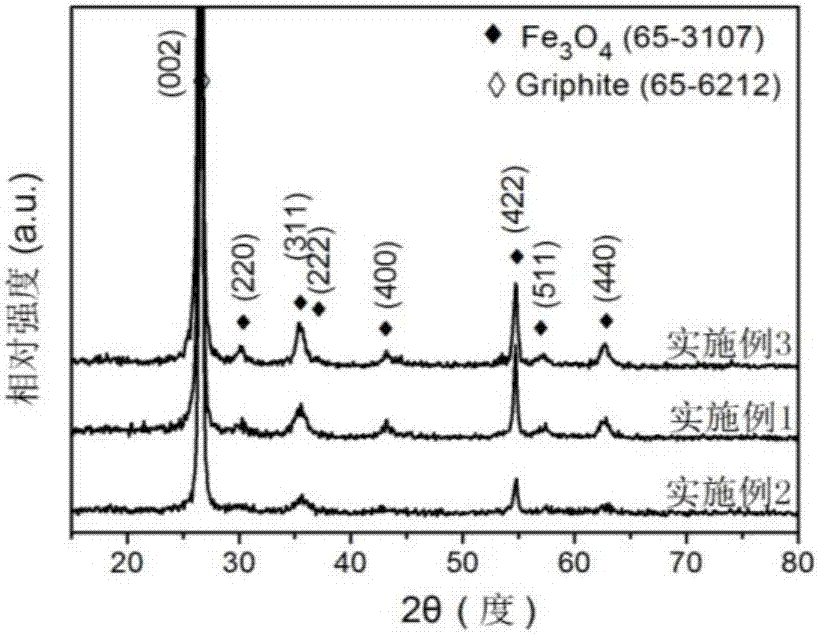

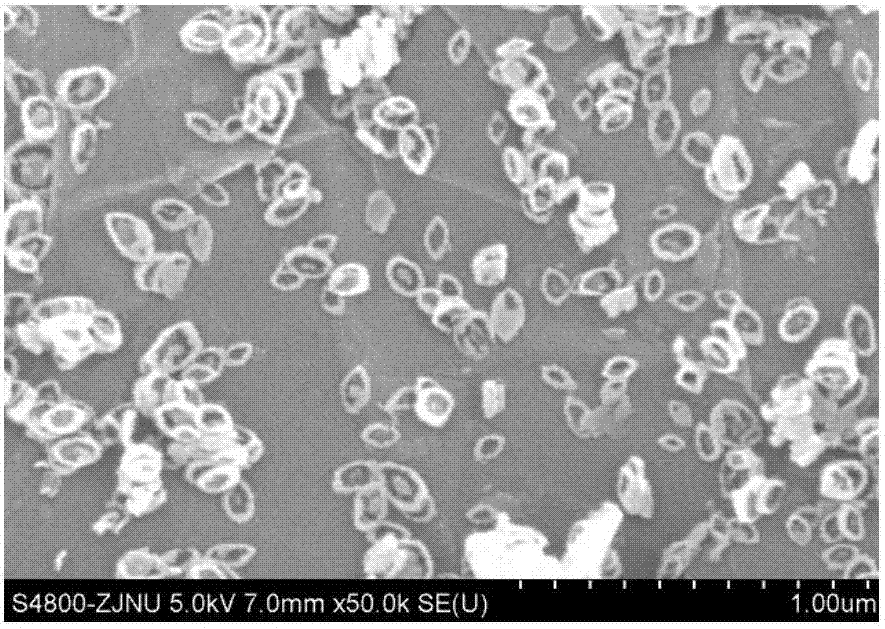

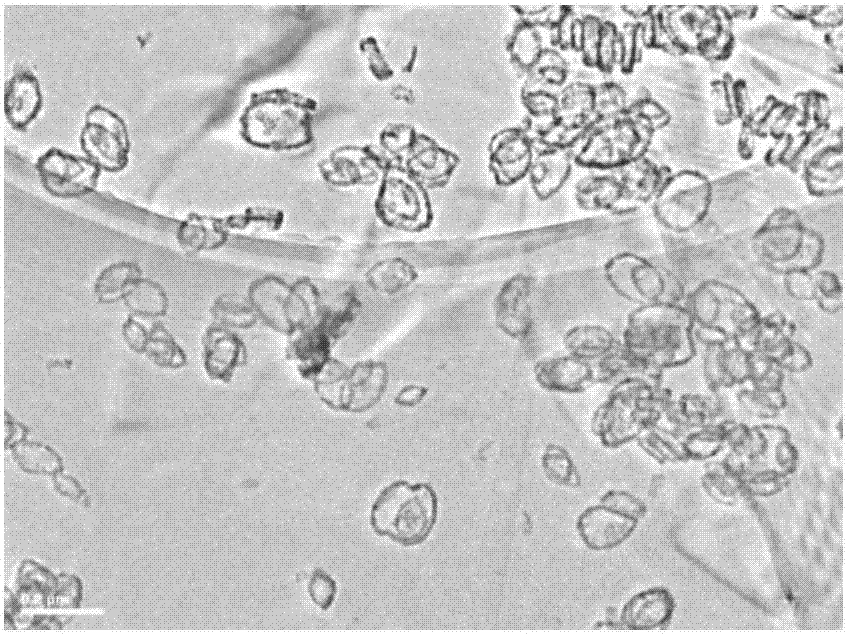

[0043] The obtained electromagnetically reinforced carbon-magnetic composite material, its phase, morphology and structure observed under scanning electron microscope and transmission electron microscope are as follows Figure 1~3 As shown, the product is Fe 3 o 4 Composite with expanded graphite, the expanded graphite is 120-850 μm long and 60-260 μm wide, and its surface is evenly distributed with ellip...

Embodiment 2

[0046] The steps are the same as in Example 1, but the calcination temperature is 300°C. Gained electromagnetically reinforced carbon-magnetic composite material, its physical phase is as figure 1 As shown, the product is Fe 3 o 4 and expanded graphite composite; its static magnetic properties such as Figure 8 As shown, the saturation magnetization is 12.01emu·g -1 , the coercive force is 40.57Oe; its electromagnetic parameters are as Figure 9-10 As shown, the real part and imaginary part of the dielectric constant increase by 0.5 to 22 and 6.5 to 90 times compared with expanded graphite in the frequency range of 2 to 18 GHz, and the real and imaginary parts of the magnetic permeability relative to Fe 3 o 4 Nanorings increased by 3-4 and 2.5-19.5 times, respectively.

Embodiment 3

[0048] The steps are the same as in Example 1, but the calcination temperature is 500°C. Gained electromagnetically reinforced carbon-magnetic composite material, its physical phase is as figure 1 As shown, the product is Fe 3 o 4 and expanded graphite composites. Its static magnetic properties are as Figure 8 As shown, the saturation magnetization is 10.88emu·g -1 , the coercive force is 63.57Oe; its electromagnetic parameters are as Figure 9-10 As shown, the real part and imaginary part of the dielectric constant increase by 0.5 to 7 and 4.5 to 160 times compared with expanded graphite in the frequency range of 2 to 18 GHz, and the real part and imaginary part of the magnetic permeability relative to Fe 3 o 4 The nanorings increased by 2-2.5 and 3-7.5 times respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com