A method for anti-seizure of ti alloy workpiece

A workpiece and alloy technology, applied in the field of ionic material surface treatment, can solve the problems of reducing equipment stability and service life, strain on the surface of threaded fasteners, difficulty in maintenance and disassembly, etc., to improve the overall use stability and service life, titanium The effect of improving the surface properties of the alloy and the good bonding performance of the film base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of the coating of embodiment 1;

[0029] Gasoline for parts cleaning conforms to GB 17930-2011 / XG1-2012 standard;

[0030] The organic solvent used for parts cleaning conforms to the GB / T 6026-1998 standard;

[0031] High-purity argon gas (purity ≥99.99%) for ion beam cleaning for plating conforms to GB / T4842-1995 standard;

[0032] High-purity nitrogen (purity ≥99.99%) for coating reaction gas conforms to GB / T 8980-1996 standard;

[0033] Industrial pure titanium (Ti) used for coating targets conforms to GB / T 6611-1996 standard;

[0034] The workpiece to be processed is a Ti alloy workpiece.

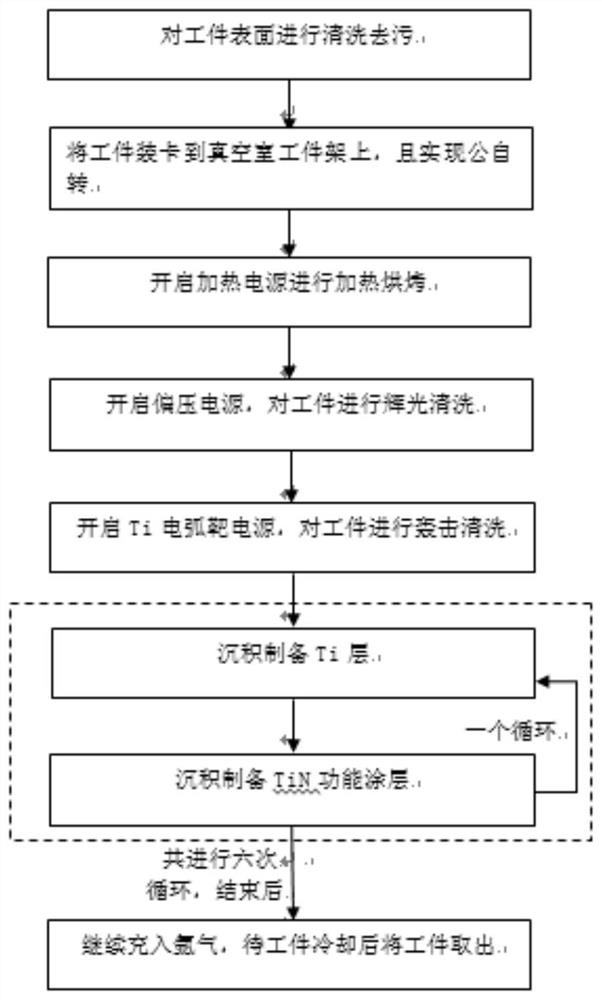

[0035] like figure 1 As shown, a method for preventing seizure of a Ti alloy workpiece includes the following steps:

[0036] Step 1. Ultrasonic degreasing and cleaning of Ti alloy workpieces with gasoline and organic solvents, and then drying with argon; all parts inside the vacuum chamber are scrubbed with absolute ethanol, and then dried.

[0037] Step 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com