Heat insulation mortar, preparation method of heat insulation mortar, heat insulation soft porcelain, preparation method of heat insulation soft porcelain, and building material

A heat-insulating mortar and soft porcelain technology, applied in the field of materials, can solve problems such as insufficient flexibility of building facing sheets, cracking of external wall insulation systems, cracking of building facing sheets, etc., to achieve good heat insulation effect, Good heat insulation and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides a method for preparing the above-mentioned heat-insulating mortar. The heat-insulating mortar firstly disperses airgel, adhesive, fiber, and aluminum silicate in water to prepare a mixed glue, and then mixes the mixed glue Add it to the inorganic powder while stirring, and add water while stirring to obtain a heat-insulating mortar. The preparation method has the advantages of simple process, convenient operation, low preparation energy consumption and environmental friendliness in the preparation process.

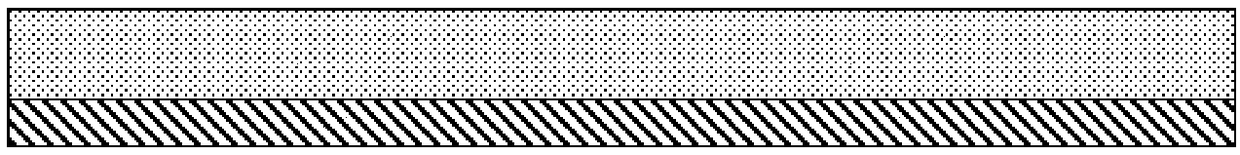

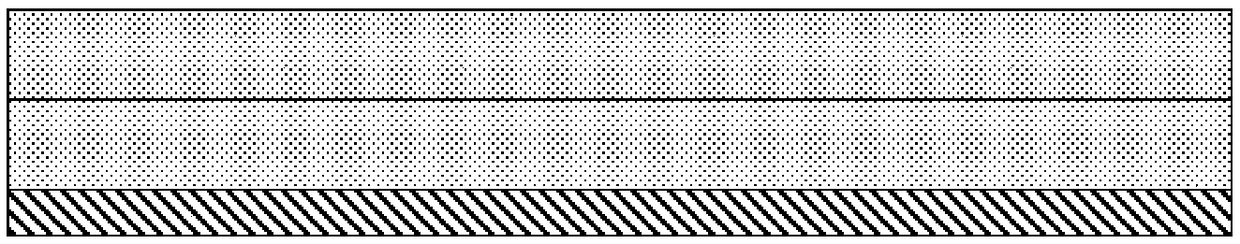

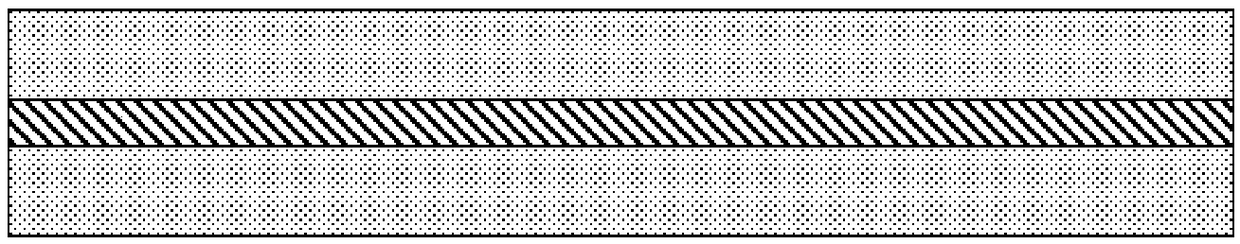

[0074] The present invention also provides a heat-insulating soft porcelain mainly prepared from the above-mentioned heat-insulating mortar. Soft porcelain is an environmentally friendly and ecological building material. In addition, soft porcelain building decoration materials are extremely expressive. Create personalized forms of expression according to the design requirements of architects and designers. The present invention...

Embodiment 1

[0090] This embodiment provides a kind of heat-insulation mortar, and this heat-insulation mortar comprises following raw material by weight percentage: Inorganic powder 65%, particle size is the nanometer SiO of 5-50nm 2 Airgel 5%, adhesive 2%, lignocellulose 1%, polypropylene fiber 0.15% and aluminum silicate 15%; the balance is water;

[0091] Wherein the inorganic powder is chernozem and meadow soil with a mass ratio of 3:1;

[0092] The adhesive includes the following raw materials in parts by weight: 20 parts of water-soluble acrylic rubber powder, 0.5 parts of polyvinyl alcohol, 5 parts of polyethylene oxide, and 2 parts of hydroxypropyl methylcellulose;

[0093] The insulating mortar is prepared as follows:

[0094] a) pulverizing the inorganic powder to 60 mesh;

[0095] b) pulverizing aluminum silicate to 120 mesh;

[0096] c) Nano-SiO 2 Airgel Airgel, adhesive, fiber and additives are stirred and dispersed evenly in the society to prepare a mixed glue;

[0097]...

Embodiment 2

[0099] This embodiment provides a kind of heat-insulation mortar, and this heat-insulation mortar comprises following raw material by weight percentage: Inorganic powder 85%, particle diameter is the nanometer SiO of 5-50nm 2 Airgel 1%, adhesive 5.5%, lignocellulose 0.5%, polypropylene fiber 0.35% and aluminum silicate 5%; the balance is water;

[0100] Wherein the inorganic powder is red soil and river sand with a mass ratio of 4:1;

[0101] The adhesive includes the following raw materials in parts by weight: 10 parts of water-soluble acrylic rubber powder, 1.5 parts of polyvinyl alcohol, 1 part of polyethylene oxide, and 7 parts of hydroxypropyl methylcellulose;

[0102] The insulating mortar is prepared as follows:

[0103] a) pulverizing the inorganic powder to 200 mesh;

[0104] b) pulverizing aluminum silicate to 80 mesh;

[0105] c) Nano-SiO 2 Airgel Airgel, adhesive, fiber and additives are stirred and dispersed evenly in the society to prepare a mixed glue;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com