Processing method of anti-ageing PTC heating component

A technology of heating components and processing methods, applied in chemical instruments and methods, heating element materials, ohmic resistance heating parts, etc., can solve the problems of reducing the service life of PTC heating components, easy aging of electrode sheets, etc., and reduce ineffective power consumption , avoid leakage phenomenon, and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

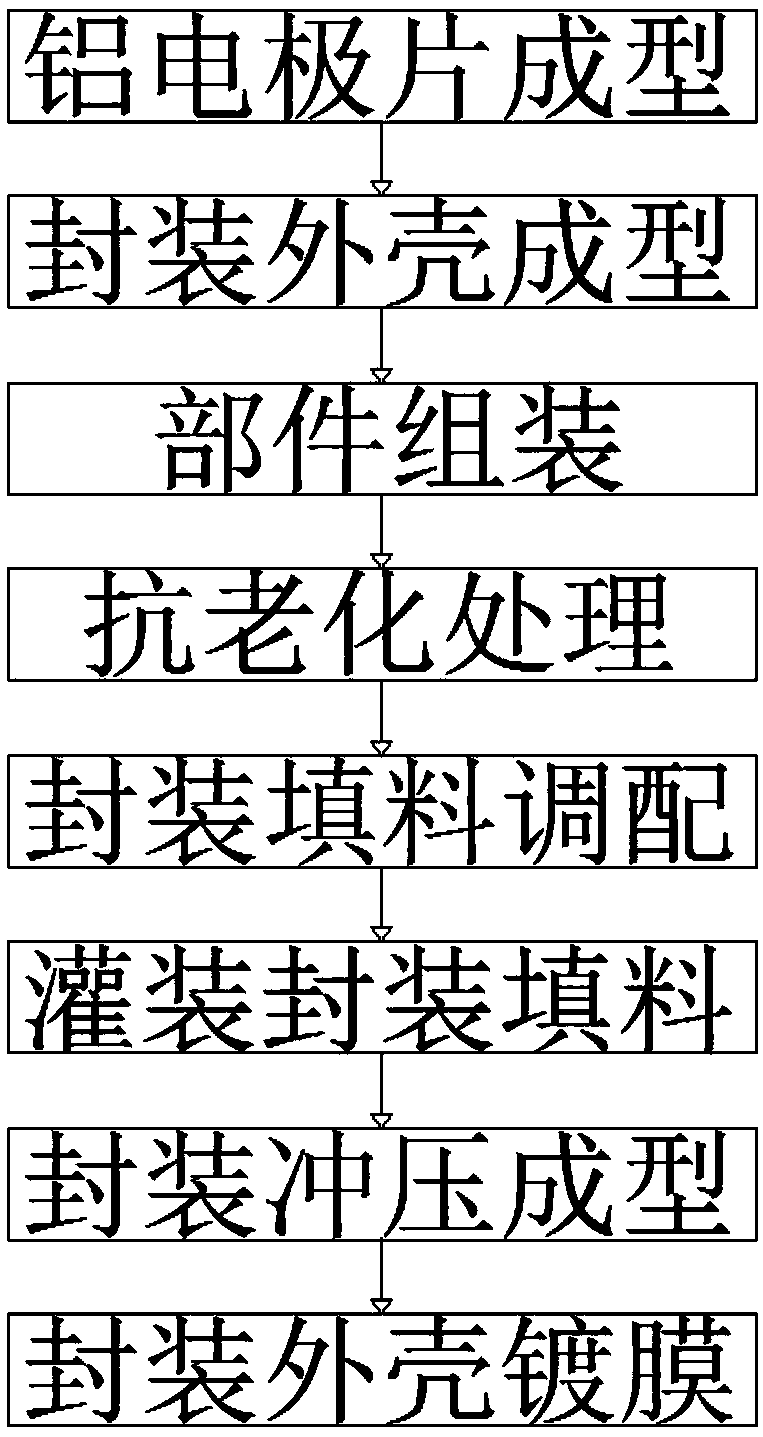

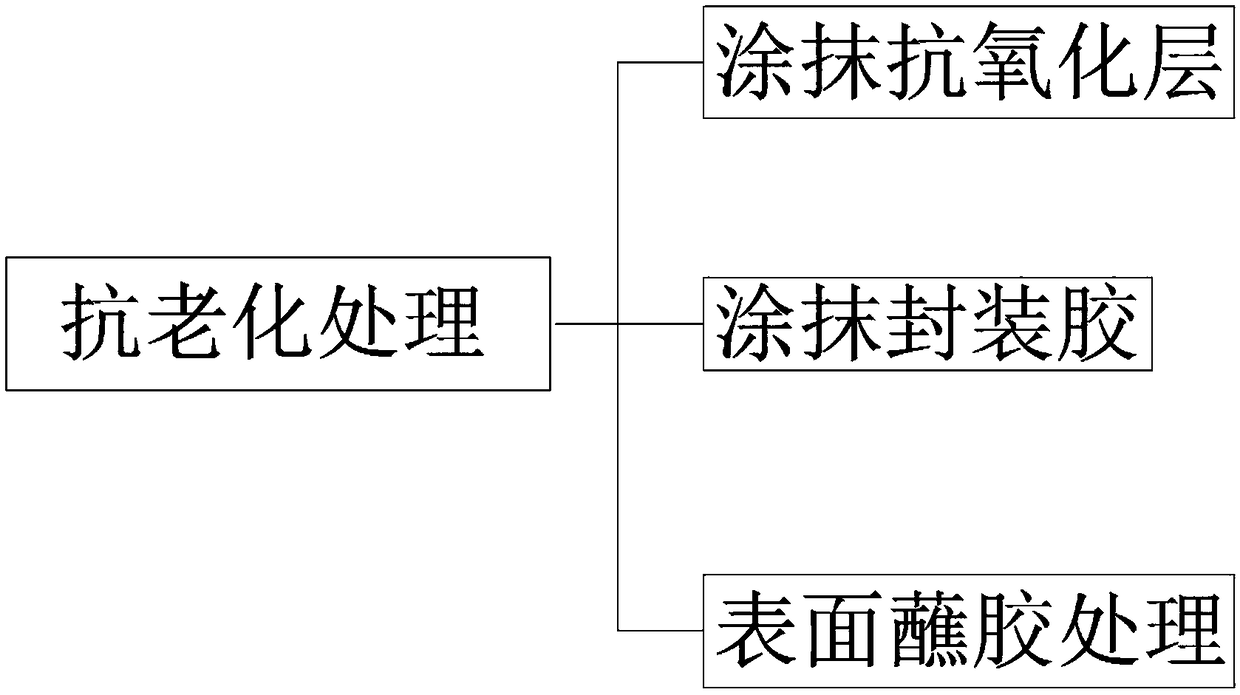

[0025] refer to Figure 1-2 , a processing method of an anti-aging PTC heating component, comprising the following steps:

[0026] S1: Forming the aluminum electrode sheet, cutting the aluminum electrode sheet into shape by cutting equipment, and nickel-plating the surface of the aluminum electrode sheet;

[0027] S2: Encapsulation and shell forming, stamping and forming metal materials into a suitable shell shape by stamping equipment, and performing surface electroplating treatment on the semi-finished shell after stamping and forming;

[0028] S3: Assembling components, attach the two aluminum electrode sheets after nickel plating to both sides of the PTC sheet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com