High-strength electric-conduction elastic Cu-Ti-Ni-Y alloy and preparation method thereof

A cu-ti-ni-y, high-strength technology, applied in the field of metal materials, can solve the problems of poor conductivity of Cu-Ti alloys, etc., and achieve the effect of improving the conductivity of the alloy, increasing the hardness of the alloy, and refining the crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

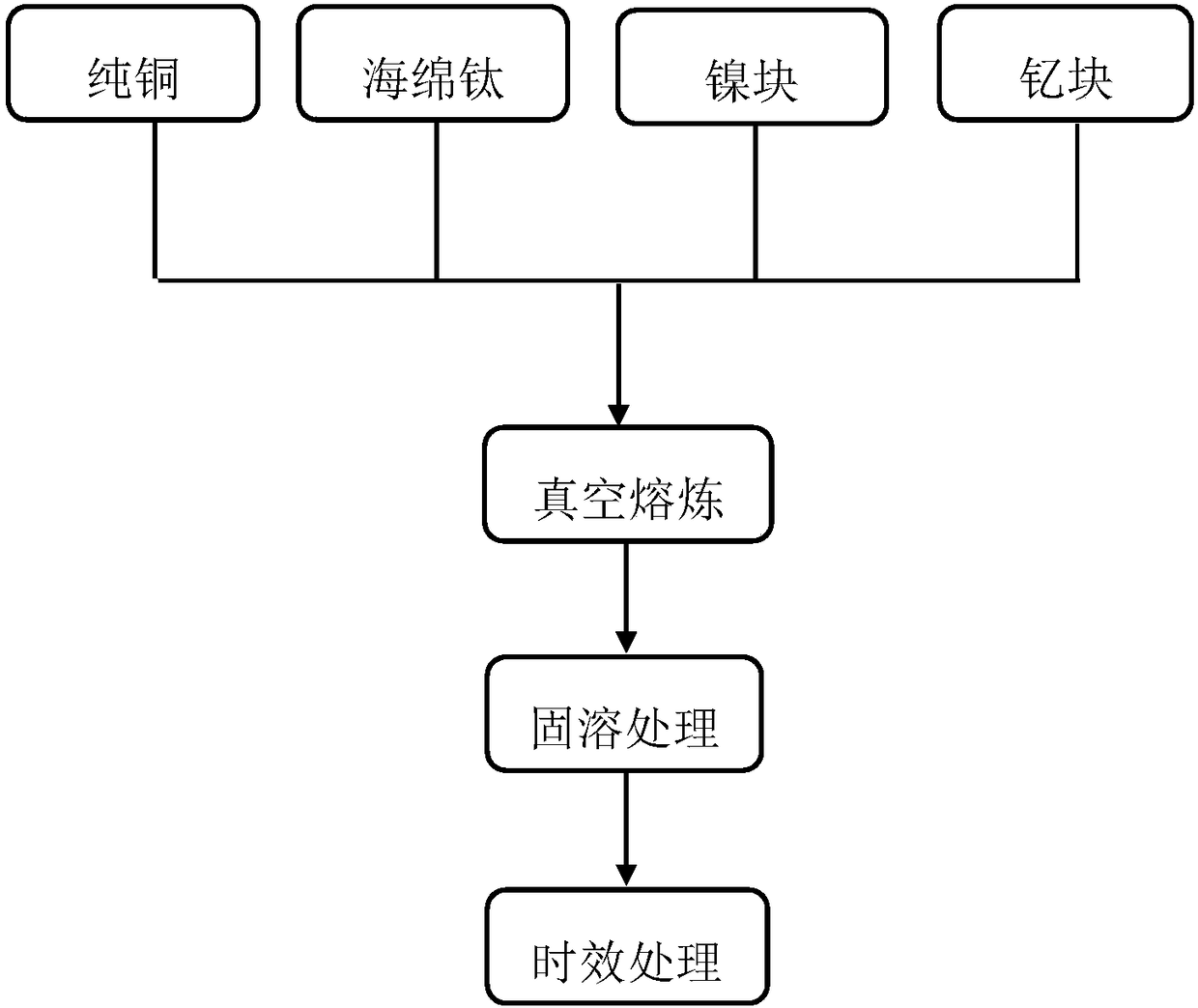

Method used

Image

Examples

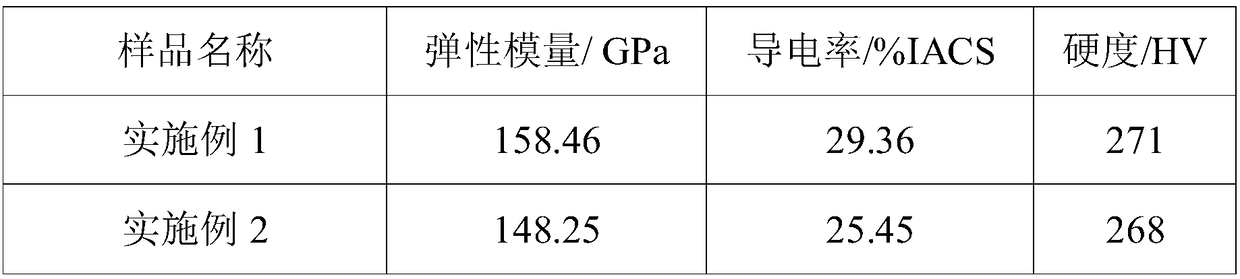

Embodiment 1

[0027] Step 1, weigh the following materials: 9.255 kg of copper block with a purity of not less than 99.9%, 0.015 kg of yttrium block with a purity of not less than 99.9%, 0.35 kg of titanium sponge with a purity of not less than 99.9%, and 0.38 kg of a nickel block with a purity of not less than 99.9%. kg;

[0028] Step 2, put the copper block, titanium sponge, nickel block and yttrium block into a magnesia crucible, and melt in a vacuum induction melting furnace with a vacuum degree of not less than 10 -3 Pa, put into water-cooled copper crucible pouring after smelting is finished, obtain alloy ingot;

[0029] Step 3, put the alloy ingot into an open-type vacuum-atmosphere tube furnace, pass in protective gas argon, and carry out solution treatment. The solution treatment temperature is 780-980° C. Carry out water quenching treatment, the temperature of the water quenching water is 20-30°C, and obtain the alloy ingot after solid solution treatment;

[0030] Step 4, put th...

Embodiment 2

[0032] Step 1, weigh the following materials: 9.549 kg of copper block with a purity of not less than 99.9%, 0.001 kg of yttrium block with a purity of not less than 99.9%, 0.2 kg of titanium sponge with a purity of not less than 99.9%, and 0.25 kg of a nickel block with a purity of not less than 99.9%. kg;

[0033] Step 2, put the copper block, titanium sponge, nickel block and yttrium block into a magnesia crucible, and melt in a vacuum induction melting furnace with a vacuum degree of not less than 10 -3 Pa, put into water-cooled copper crucible pouring after smelting is finished, obtain alloy ingot;

[0034] Step 3, put the alloy ingot into an open-type vacuum-atmosphere tube furnace, pass in protective gas argon, and carry out solution treatment. The solution treatment temperature is 780-980° C. Carry out water quenching treatment, the temperature of the water quenching water is 20-30°C, and obtain the alloy ingot after solid solution treatment;

[0035] Step 4, put the...

Embodiment 3

[0037] Step 1, weigh the following materials: 9.3 kg of copper block with a purity of not less than 99.9%, 0.1 kg of yttrium block with a purity of not less than 99.9%, 0.3 kg of titanium sponge with a purity of not less than 99.9%, and 0.3 kg of a nickel block with a purity of not less than 99.9%. kg;

[0038] Step 2, put the copper block, titanium sponge, nickel block and yttrium block into a magnesia crucible, and melt in a vacuum induction melting furnace with a vacuum degree of not less than 10 -3 Pa, put into water-cooled copper crucible pouring after smelting is finished, obtain alloy ingot;

[0039] Step 3, put the alloy ingot into an open-type vacuum-atmosphere tube furnace, pass through the protective gas argon, and carry out heat preservation treatment. The heat preservation temperature is 780-980 ° C, heat preservation for 3-6 hours, and then quenching treatment, the temperature of the quenching water is 20-30°C, and an alloy ingot after solid solution treatment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com