Modified PA66 composite material and preparation method thereof

A composite material, PA66 technology, applied in the field of modified PA66 composite material and its preparation, can solve the problems of unfavorable application and promotion of PA66, poor product dimensional stability, poor resistance to strong acid and strong alkali, etc., and achieve good hiding power and good chemical stability , good friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

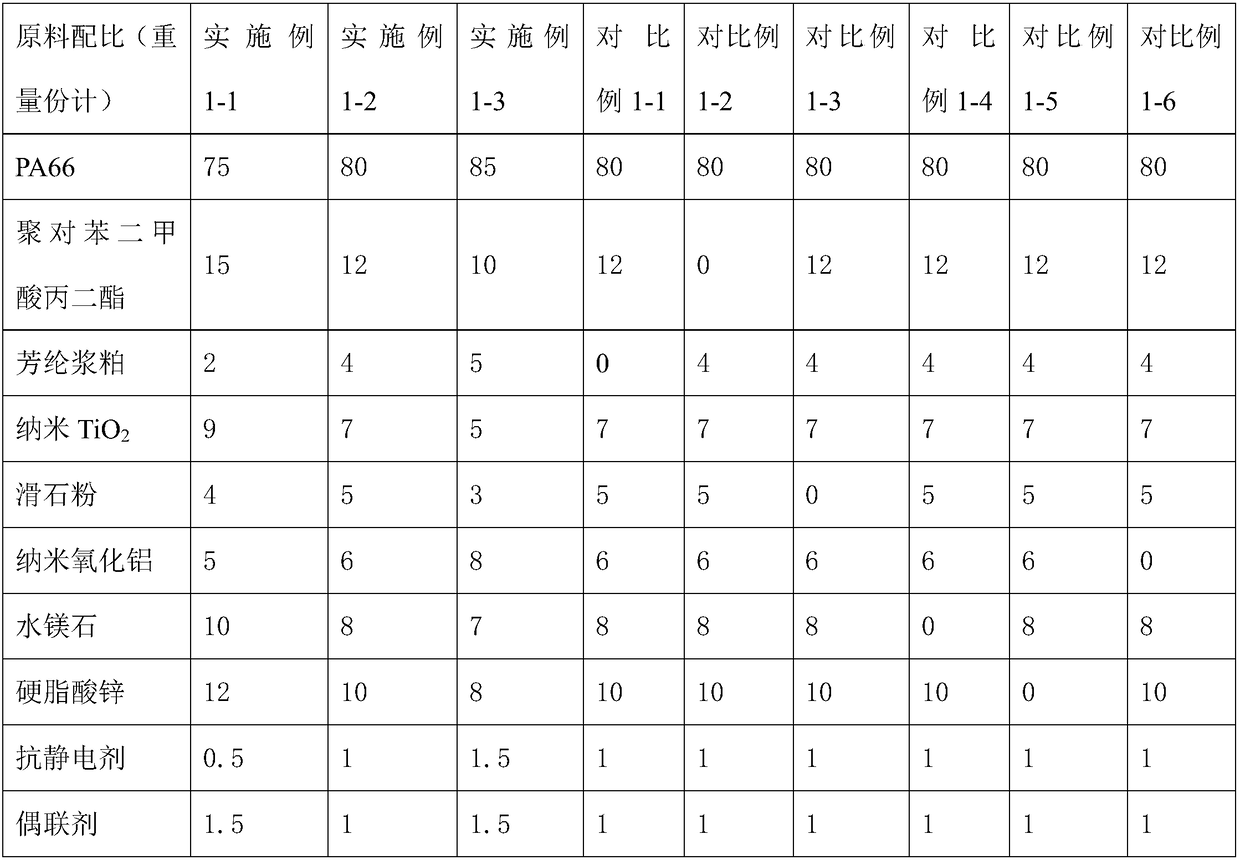

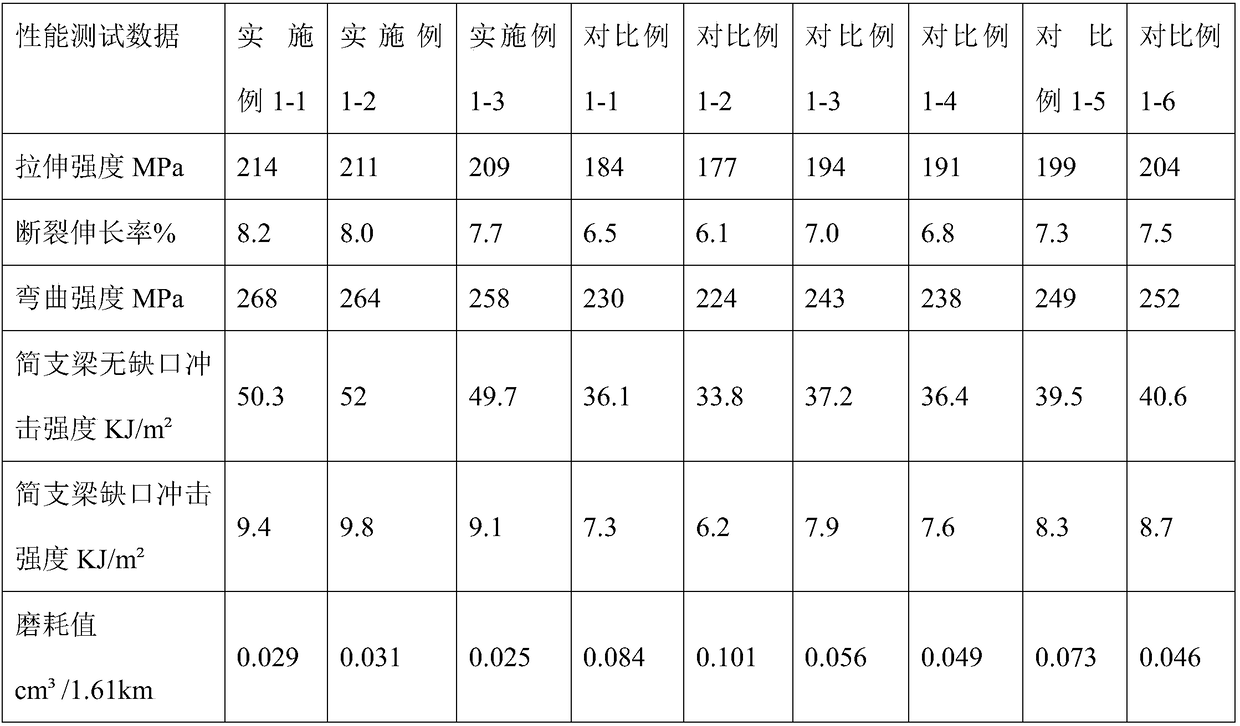

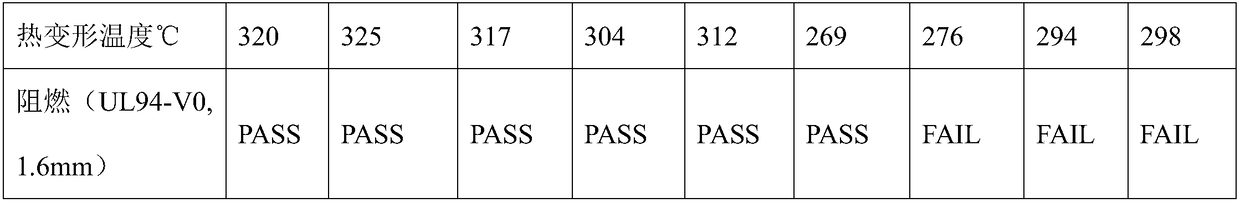

Examples

Embodiment 1

[0026] A modified PA66 composite material, comprising the following components: PA66, polytrimethylene terephthalate, aramid pulp, nano TiO 2 , talcum powder, nano alumina, brucite, zinc stearate, antistatic agent and coupling agent.

[0027] Among them, the antistatic agent is sodium dodecylbenzenesulfonate; the coupling agent is γ-(2,3-epoxypropoxy)propyltrimethoxysilane; nano-TiO 2 The particle size is 50-300nm; the nano-alumina particle size is 500-800nm.

[0028] Preparation:

[0029] (1) get each component by weight and prepare materials;

[0030] (2) PA66, polytrimethylene terephthalate, aramid pulp, antistatic agent and coupling agent are mixed to prepare premix I through high mixer;

[0031] (3) Premix I is extruded through a co-rotating twin-screw extruder, and composite material I is obtained after water cooling, air cooling, and granulation;

[0032] (4) Composite material I, nano TiO 2 , talcum powder, nano-alumina, brucite, and zinc stearate are mixed by a h...

Embodiment 2

[0053] A modified PA66 composite material, comprising the following components in parts by weight: 80 parts of PA66, 12 parts of polytrimethylene terephthalate, 4 parts of aramid pulp, nano TiO 2 7 parts, 5 parts of talcum powder, 6 parts of nano-alumina, 8 parts of brucite, 10 parts of zinc stearate, 1 part of antistatic agent and 1 part of coupling agent.

[0054] Among them, the antistatic agent is sodium dodecylbenzenesulfonate; the coupling agent is γ-(2,3-epoxypropoxy)propyltrimethoxysilane; nano-TiO 2 The particle size is 50-300nm; the nano-alumina particle size is 500-800nm.

[0055] Preparation method 1:

[0056] (1) get each component by weight and prepare materials;

[0057] (2) PA66, polytrimethylene terephthalate, aramid pulp, antistatic agent and coupling agent are mixed to prepare premix I through high mixer;

[0058] (3) Premix I is extruded through a co-rotating twin-screw extruder, and composite material I is obtained after water cooling, air cooling, and ...

Embodiment 3

[0076] A modified PA66 composite material, comprising the following components in parts by weight: 77 parts of PA66, 16 parts of polytrimethylene terephthalate, 5 parts of aramid pulp, nano TiO 2 5 parts, 7 parts of talcum powder, 5 parts of nano-alumina, 10 parts of brucite, 12 parts of zinc stearate, 0.5 parts of antistatic agent and 2 parts of coupling agent.

[0077] Among them, the antistatic agent is sodium dodecylbenzenesulfonate; the coupling agent is γ-(2,3-epoxypropoxy)propyltrimethoxysilane; the particle size of nano-TiO2 is 50-300nm; nano-alumina The particle size is 500-800nm.

[0078] Preparation method 1:

[0079] (1) get each component by weight and prepare materials;

[0080] (2) PA66, polytrimethylene terephthalate, aramid pulp, antistatic agent and coupling agent are mixed to prepare premix I through high mixer;

[0081] (3) Premix I is extruded through a co-rotating twin-screw extruder, and composite material I is obtained after water cooling, air cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com