Preparation method of triptyl polyimide separating film

A technology of pterene-based polyimide and separation membrane, which is applied in separation methods, semi-permeable membrane separation, dispersion particle separation, etc., to achieve the effects of increasing solubility, good self-stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

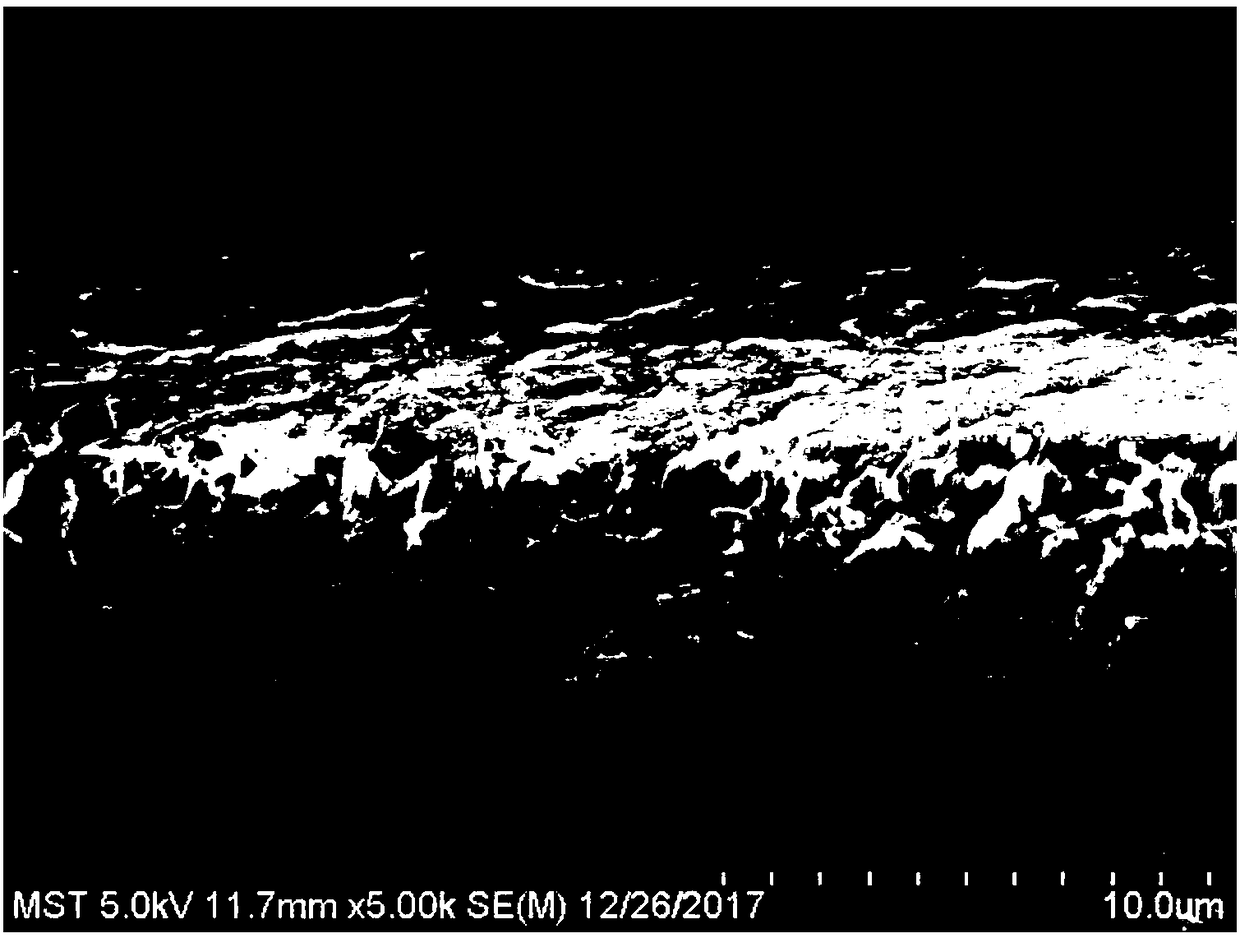

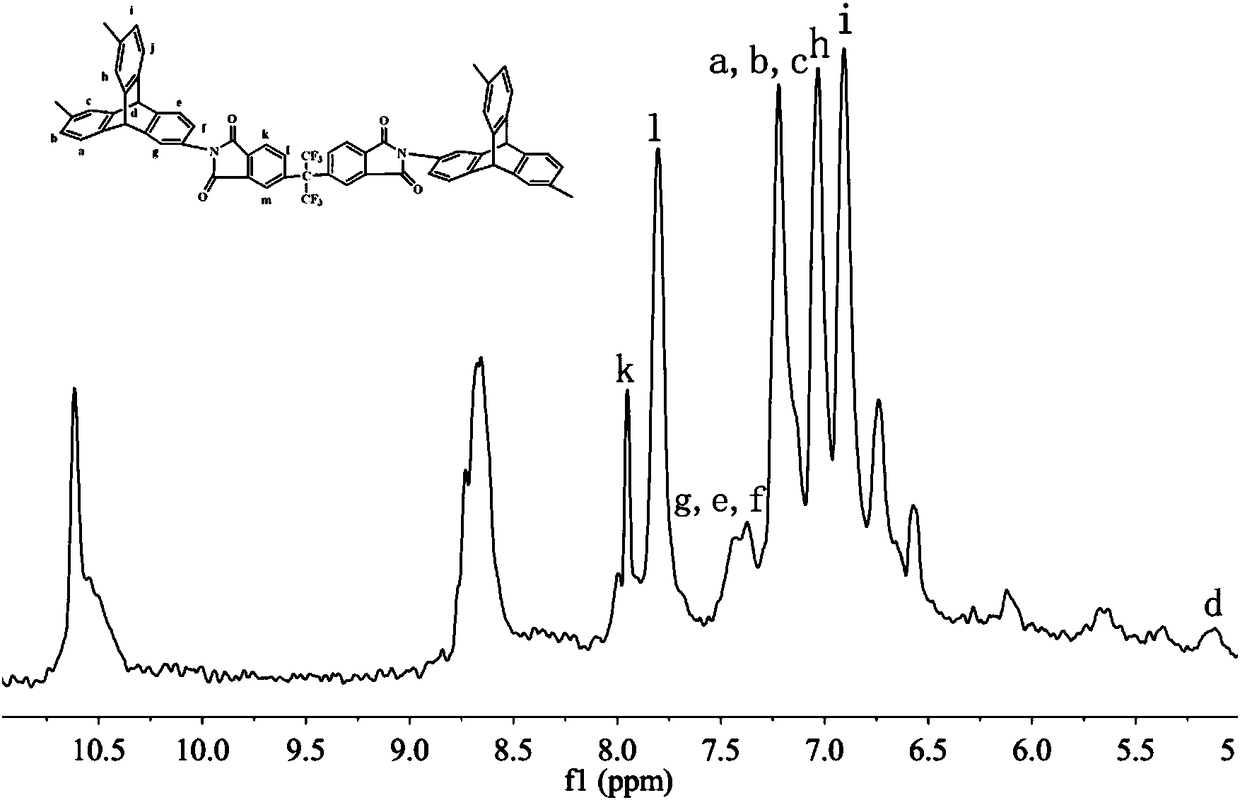

[0038] Take 0.45g (1.5mmol) of 2,6,14-triaminotriptycene, put it into a 250ml flask, keep the temperature in an ice bath at about 0°C, then add 50ml of dimethylformamide to stir and dissolve, and add it in the form of powder 1.0 g (2.25 mmol) of hexafluorodianhydride was stirred and reacted for 6 hours under nitrogen protection. The ice bath was removed, 10 ml of acetic anhydride and 6 ml of pyridine were added thereto, and the reaction was stirred for 24 hours under nitrogen protection. After the reaction, configure 1L of methanol aqueous solution with a volume ratio of 1:1, pour the reaction product into the methanol aqueous solution, stir vigorously for 10 minutes, filter with suction, and dry the filter cake under vacuum at 50°C to obtain 0.9232g of Phenyl polyimide polymer.

[0039] Its structure is via 1 H-NMR and 1 C-NMR characterization confirmation, 1 H-NMR (500MHz, DMSO), δ=7.80-8.00ppm is the characteristic absorption peak of the H atom on the benzene ring of he...

Embodiment 2

[0043] Take 0.4g (1.34mmol) of 2,6,14-triaminotriptycene, put it into a 250ml flask, keep the temperature in an ice bath at about 0°C, then add 40ml of methylpyrrolidone to stir and dissolve, and add 0.52g in powder form (1.68mmol) 4,4'-biphenyl ether dianhydride, stirred and reacted for 8 hours under the protection of nitrogen. The ice bath was removed, 8 ml of acetic anhydride and 8 ml of triethylamine were added thereto, and the reaction was stirred for 24 hours under nitrogen protection. After the reaction, configure 1 L of methanol aqueous solution with a volume ratio of 1:1, pour the reaction product into the methanol aqueous solution, stir vigorously for 12 minutes, filter with suction, and dry the filter cake under vacuum at 60°C to obtain 0.6760 g of Phenyl polyimide polymer.

[0044] Its structure is via 1 H-NMR and 1 Confirmation by C-NMR characterization. 1 H-NMR (500 MHz, DMSO). δ=7.80-7.90ppm is the characteristic absorption peak of the H atom on the benzene...

Embodiment 3

[0048] Take 0.38g (1.27mmol) of 2,6,14-triaminotriptycene, put it into a 250ml flask, keep the temperature in an ice bath at about 0°C, then add 35ml of dimethylacetamide to stir and dissolve, and add it in the form of powder 0.5 g (1.55 mmol) of 3,3',4,4'-benzophenone tetracarboxylic dianhydride was stirred and reacted for 5 hours under nitrogen protection. The ice bath was removed, 6ml of acetic anhydride and 15ml of pyridine were added thereto, and the reaction was stirred for 36 hours under the protection of nitrogen. After the reaction, the reaction product was poured into methanol, vigorously stirred for 15 minutes, filtered with suction, and the filter cake was dried under vacuum at 70° C. to obtain 0.6120 g of triptyl polyimide polymer.

[0049] Its structure is via 1 H-NMR and 1 Confirmation by C-NMR characterization. 1 H-NMR (500 MHz, DMSO). δ=8.10-8.20ppm is the characteristic absorption peak of the H atom on the benzene ring of 3,3',4,4'-benzophenonetetracarbox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com