Method for modifying nano silica

A nano-silica and modification technology, which is applied in the treatment of dyed low-molecular-weight organic compounds, dyed high-molecular organic compounds, fibrous fillers, etc. Good chemical stability, good lipophilic and hydrophobic properties, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

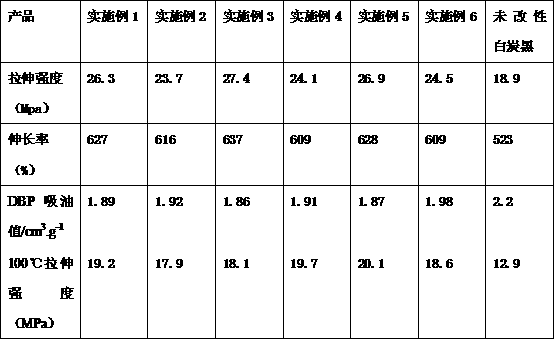

Examples

Embodiment 1

[0028] A modification method of nano white carbon black, comprising the following steps:

[0029] S1: adding nano-silica to water, stirring and mixing evenly to obtain a nano-silica slurry with a mass concentration of 25%;

[0030] S2: Transport the nano-silica obtained in step S1 to a surface treatment machine, heat it to 70°C, and then add a first surface treatment agent with a weight of 3% nano-silica, and the first surface treatment agent has a mass ratio of 2 : 1 stearic acid and fatty alcohol polyoxyethylene ether sodium sulfate are formed, and at rotating speed, be 150r / min and stir 45min, finish the first surface modification of nano white carbon black;

[0031] S3: dehydrating the nano-silica obtained by modifying step S2, drying in a chain-belt dryer at 80° C., pulverizing, and grading to obtain nano-silica powder;

[0032] S4: Transport the nano-silica obtained in step S3 to a high-speed mixer, control the temperature of the material to 70°C, and then add alkylphen...

Embodiment 2

[0034] A modification method of nano white carbon black, comprising the following steps:

[0035] S1: adding nano-silica to water, stirring and mixing evenly to obtain a nano-silica slurry with a mass concentration of 20%;

[0036] S2: Transport the nano-silica obtained in step S1 to a surface treatment machine, heat it to 60°C, and then add a first surface treatment agent with a weight of 3.5% of the nano-silica, and the first surface treatment agent has a mass ratio of 1 : 1 palmitic acid and fatty alcohol polyoxyethylene ether sodium sulfate are formed, and at rotating speed, be 300r / min and stir 30min, finish the first surface modification of nano white carbon black;

[0037] S3: dehydrating the nano-silica obtained by modifying step S2, drying at 100° C. in a chain-belt dryer, pulverizing, and grading to obtain nano-silica powder;

[0038] S4: Transport the nano-silica obtained in step S3 to a high-speed mixer, control the material temperature to 60°C, and then add alkyl...

Embodiment 3

[0040] A modification method of nano white carbon black, comprising the following steps:

[0041] S1: adding nano-silica to water, stirring and mixing evenly to obtain a nano-silica slurry with a mass concentration of 30%;

[0042] S2: Transport the nano-silica obtained in step S1 to a surface treatment machine, heat it to 75°C, and then add a first surface treatment agent with a weight of 4% nano-silica, and the first surface treatment agent has a mass ratio of 3 :1 lauric acid and fatty alcohol polyoxyethylene ether sodium sulfate are formed, and at rotating speed, be 300r / min and stir 60min, finish the surface modification of nano white carbon black for the first time;

[0043] S3: Dehydrating the nano-silica obtained by modifying step S2, drying in a chain-belt dryer at 90° C., pulverizing, and grading to obtain nano-silica powder;

[0044] S4: Transport the nano-silica obtained in step S3 to a high-speed mixer, control the material temperature to 75°C, and then add alkyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com