Photovoltaic welding strip alloy solder and preparation method thereof

A photovoltaic welding ribbon and alloy technology, applied in the field of solar photovoltaic power generation, can solve the problems of unfavorable customers' welding use, poor oxidation resistance, and rising melting point of alloys, and achieve the effects of reducing the generation of slag, low cost, and lowering the melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

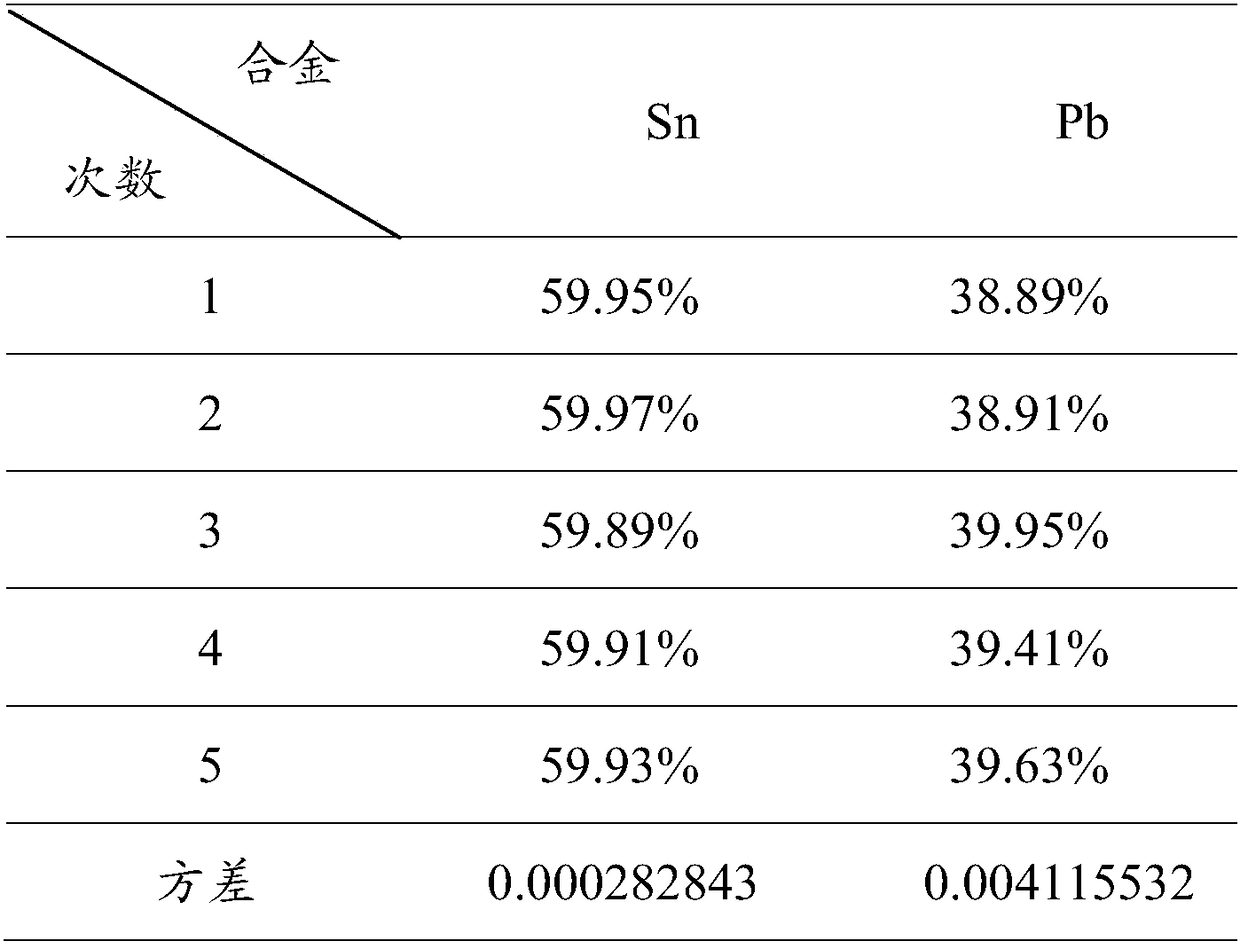

Embodiment 1

[0023] A photovoltaic ribbon alloy solder, comprising the following preparation steps:

[0024] 1. Raw material components for preparing photovoltaic ribbon alloy solder

[0025] 1) Preparation of tin-lead alloy

[0026] The atmosphere protection melting furnace is adopted, the temperature range is 100-1500 ℃, the protection gas used is high-purity nitrogen or argon, and the purity requirement is 99.999%. Weigh 600g of tin and 400g of lead respectively, mix them in a quartz dry pot, heat and melt them in a vacuum melting furnace, and set the temperature at 350±5°C. Before starting the furnace, turn on the cooling circulating water and feed in nitrogen for 10 minutes. After the pressure gauge at the exhaust port becomes constant, start heating and directly heat to the set temperature of 350±5°C. After half an hour, turn off the heating switch and continue to feed in nitrogen. . After the temperature of the heating cabin becomes below 45°C, open the cabin door to obtain a tin...

Embodiment 2

[0052] A photovoltaic ribbon alloy solder, its raw material components and its preparation method are the same as in Example 1, the difference is that in the raw material components of the photovoltaic ribbon alloy solder, the addition of bismuth indium phosphide cerium neodymium gallium copper accounted for 1% of tin lead 0.03%, 0.04%, 0.004%, 0.003%, 0.002%, 0.003%, 0.003%, 0.12% of the alloy mass.

Embodiment 3

[0054] A photovoltaic ribbon alloy solder, its raw material components and its preparation method are the same as in Example 2, the difference is that the intermediate alloy A of the photovoltaic ribbon alloy solder does not contain gallium and the intermediate alloy B does not contain copper elements, bismuth indium phosphorus The added amounts of cerium, neodymium and germanium account for 0.03%, 0.05%, 0.004%, 0.003%, 0.002%, and 0.003% of the mass of the tin-lead alloy, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com