Lithium ion battery negative electrode slurry and lithium ion battery

A lithium-ion battery and negative electrode slurry technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of easy reduction of lithium-ion battery charge and discharge performance and use safety, the impact of battery volume specific capacity, Problems such as charging efficiency and speed, to achieve the effect of maintaining stability, ensuring basic performance, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Although the preparation of lithium ion battery cathode slurry, the selection of positive and negative current collectors, electrolyte formula, diaphragm selection, and battery assembly are quite important, they are not relevant based on the present invention and can be carried out according to the prior art The selection will not be described in detail here, and the corresponding lithium ion negative electrode slurry will be described below.

[0028] The technical scheme of the lithium ion battery negative electrode slurry will be further described below through specific implementation methods.

Embodiment 1

[0030] A negative electrode slurry for a lithium ion battery is provided in Embodiment 1,

[0031] Preparation of lithium ion battery negative electrode sheet:

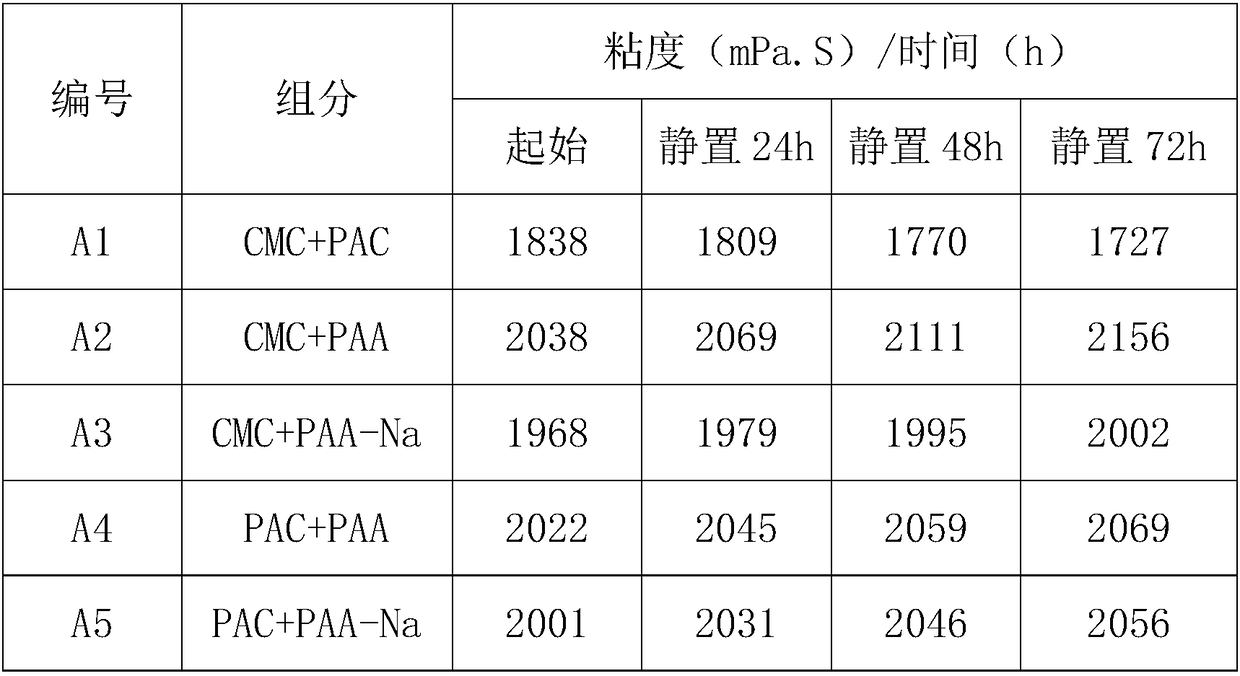

[0032] 3868 grams of artificial graphite, 6 grams of CMC with a molecular weight of 400,000, 6 grams of PAC with a molecular weight of 400,000, 160 grams of 50% SBR emulsion, 2830 grams of deionized water, 25.2 grams of acetylene black, 9.6 grams of carbon nanotubes, and 5.2 grams of carbon fiber VGCF, 56g of triphenyl phosphate and 14g of tetrabromophthalic anhydride were mixed and stirred evenly to obtain negative electrode slurry A1.

[0033] Coat the negative electrode slurry A1 obtained in the previous step on a copper foil with a thickness of 9um, dry at 90°C, press into sheets, and then cut into negative electrode sheets of length×width×thickness=84mm×59mm×0.11mm , Each negative electrode contains 0.86 grams of artificial graphite.

[0034] Preparation of positive electrode sheet of lithium ion battery: 3868 ...

Embodiment 2

[0038] A negative electrode slurry for a lithium ion battery is provided in Embodiment 2,

[0039] Preparation of lithium ion battery negative electrode sheet:

[0040] 3868 grams of artificial graphite, 6 grams of CMC with a molecular weight of 400,000, 6 grams of polyacrylic acid with a molecular weight of 30 million, 160 grams of SBR emulsion with a concentration of 50%, 2830 grams of deionized water, 25.2 grams of acetylene black, 9.6 grams of carbon nanotubes, 5.2 grams Carbon fiber VGCF, 48.9g of triphenyl phosphate and 20.9g of tetrabromophthalic anhydride were mixed and stirred evenly to obtain negative electrode slurry A2. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com