Method for preparing two-dimensional indium trisulfide mono-crystals on mica substrate

A technology of indium trisulfide and a substrate is applied in the field of preparing two-dimensional indium trisulfide single crystal, which can solve the problems of many crystal defects, short growth time, small crystal size and the like, and achieves simple preparation process, short growth time, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

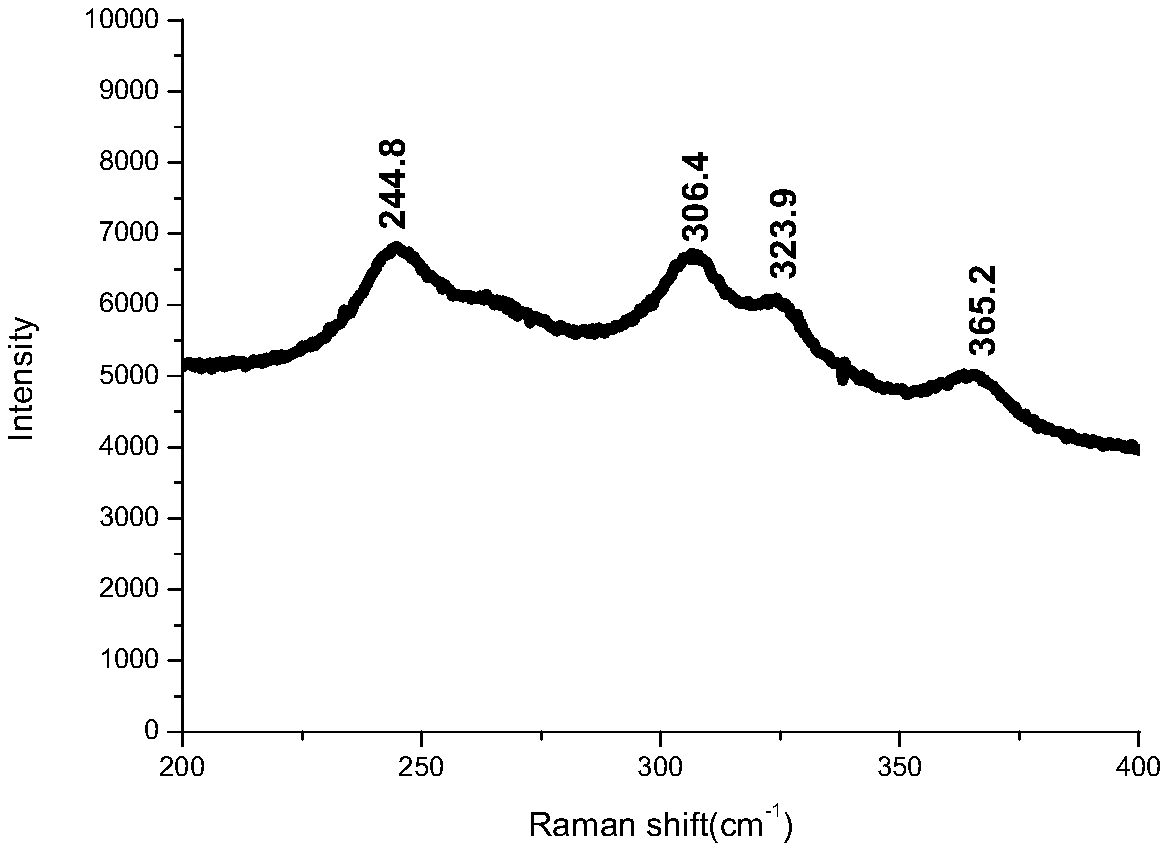

example 1

[0033] Put the mica sheet into acetone, absolute ethanol, and deionized water for 5 minutes, then rinse it with deionized water several times, and finally dry it quickly with nitrogen. Weigh 10 mg of indium trisulfide powder with an electronic balance, put the powder on a clean quartz boat, place the cleaned mica sheet on the top of the quartz boat containing indium trisulfide, and then place the indium trisulfide quartz boat Place it in the middle of the tube furnace; fully open the inlet and outlet valves of the tube furnace, open the argon bottle, adjust the gas flow meter to 600 sccm, and feed a large amount of argon into the quartz tube of the tube furnace for 10 minutes. Turn on the tube furnace, raise it from room temperature to 980 degrees within 20 minutes, reduce the air flow to 20 sccm at about 500 degrees, keep it at 980 degrees for 5 minutes, take out the sample after natural cooling, and obtain diindium trisulfide single crystal.

example 2

[0035] Put the mica sheet into acetone, absolute ethanol, and deionized water for 10 minutes, then rinse it with deionized water several times, and finally dry it quickly with nitrogen. Weigh 20 mg of indium trisulfide powder with an electronic balance, put the powder on a clean quartz boat, place the cleaned mica sheet on the top of the quartz boat containing indium trisulfide, and then place the indium trisulfide quartz boat Place it in the middle of the tube furnace; fully open the inlet and outlet valves of the tube furnace, open the argon bottle, adjust the gas flow meter to 600 sccm, and feed a large amount of argon into the quartz tube of the tube furnace for 10 minutes. Turn on the tube furnace, rise from room temperature to 980 degrees within 30 minutes, reduce the air flow to 20 sccm at about 500 degrees, keep it at 980 degrees for 10 minutes, take out the sample after natural cooling, and obtain diindium trisulfide single crystal.

example 3

[0037] Put the mica sheet into acetone, absolute ethanol, and deionized water for 30 minutes, then rinse it with deionized water several times, and finally dry it quickly with nitrogen. Weigh 30mg of indium trisulfide powder with an electronic balance, put the powder on a clean quartz boat, place the cleaned mica sheet on the top of the quartz boat containing indium trisulfide, and then put the indium trisulfide in the quartz boat Place it in the middle of the tube furnace; fully open the inlet and outlet valves of the tube furnace, open the argon bottle, adjust the gas flow meter to 600 sccm, and feed a large amount of argon into the quartz tube of the tube furnace for 10 minutes. Turn on the tube furnace, rise from room temperature to 980 degrees within 30 minutes, reduce the airflow to 20 sccm at about 500 degrees, keep it at 980 degrees for 15 minutes, take out the sample after natural cooling, and obtain diindium trisulfide single crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com