Preparation method of multifunctional sanitary-fitting hardware

A hardware and multi-functional technology, applied in the field of hardware, can solve the problems of not being able to adapt to the high requirements of elongation at break and flexural modulus, and achieve the effects of preventing moisture inflow, efficient control, and enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

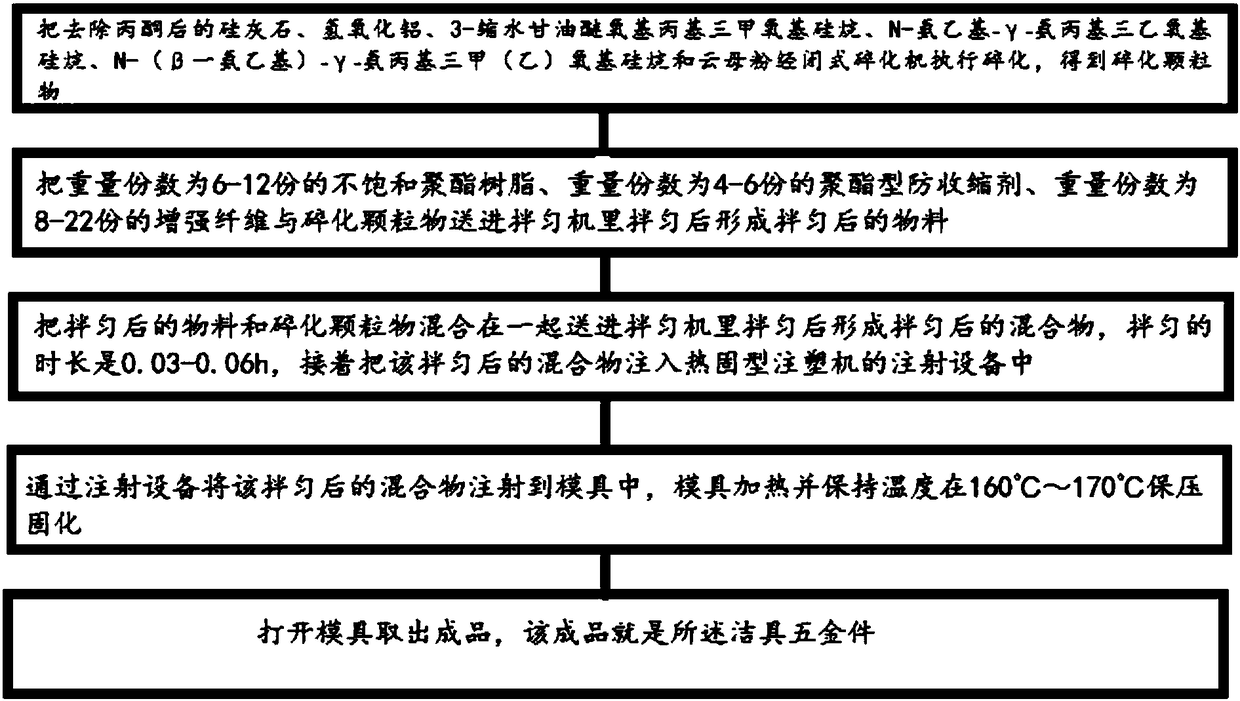

[0050] like Figure 1-Figure 5 As shown, the preparation method of multifunctional sanitary ware hardware includes the following steps:

[0051] Step a, the wollastonite that is 12 parts by weight, the aluminum hydroxide that is 4 parts by weight, the 3-glycidyl etheroxypropyl trimethoxysilane that is 0.02 part by weight, the parts by weight 0.08 parts of N-aminoethyl-γ-aminopropyltriethoxysilane and 0.02 parts by weight of N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane Pour into the 3-glycidyloxypropyltrimethoxysilane, N-aminoethyl-γ-aminopropyltriethoxysilane and N-(β-aminoethyl)-γ-aminopropyl In the acetone of 6 times of the total mass of trimethyl (ethyl) oxysilane, then the mica powder that is 10 parts by weight is also put into the acetone, the acetone is removed through the heater, and then the wollastonite and hydroxide after the acetone removal are removed Aluminum, 3-glycidyloxypropyltrimethoxysilane, N-aminoethyl-γ-aminopropyltriethoxysilane, N-(β-aminoet...

Embodiment 2

[0075] The preparation method of multifunctional sanitary ware hardware includes the following steps:

[0076] Step a, the wollastonite that is 18 parts by weight, the aluminum hydroxide that is 4-6 parts by weight, the 3-glycidyl etheroxypropyl trimethoxysilane that is 0.09 part by weight, weight Parts are 0.16 parts of N-aminoethyl-γ-aminopropyltriethoxysilane and 0.09 parts by weight of N-(β-aminoethyl)-γ-aminopropyltrimethyl (ethyl)oxy The 3-glycidyloxypropyltrimethoxysilane, N-aminoethyl-γ-aminopropyltriethoxysilane and N-(β-aminoethyl)-γ-ammonia Propyl trimethyl (ethyl) oxysilane in acetone with 6 times the total mass, then put mica powder that is 13 parts by weight into the acetone, remove the acetone through the heater, then remove the wollastonite, Aluminum hydroxide, 3-glycidyloxypropyltrimethoxysilane, N-aminoethyl-γ-aminopropyltriethoxysilane, N-(β-aminoethyl)-γ-aminopropyl Trimethyl(ethyl)oxysilane and mica powder are crushed by a closed crusher to obtain crushe...

Embodiment 3

[0100] The preparation method of multifunctional sanitary ware hardware includes the following steps:

[0101] Step a, the wollastonite that is 24 parts by weight, the aluminum hydroxide that is 6 parts by weight, the 3-glycidyl etheroxypropyl trimethoxysilane that is 0.16 part by weight, the parts by weight 0.24 parts of N-aminoethyl-γ-aminopropyltriethoxysilane and 0.16 parts by weight of N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane Pour into the 3-glycidyloxypropyltrimethoxysilane, N-aminoethyl-γ-aminopropyltriethoxysilane and N-(β-aminoethyl)-γ-aminopropyl In the acetone of 6 times of the total mass of trimethyl(ethyl)oxysilane, then the mica powder that is 10-16 parts by weight is also put into the acetone, the acetone is removed through the heater, and then the wollastonite, Aluminum hydroxide, 3-glycidyloxypropyltrimethoxysilane, N-aminoethyl-γ-aminopropyltriethoxysilane, N-(β-aminoethyl)-γ-aminopropyl Trimethyl(ethyl)oxysilane and mica powder are crushed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com