Environment-friendly, flame-retardant and injection-molding-grade ACS modified material

A modified material, injection molding grade technology, applied in the polymer field, can solve the problems of environmental protection and thermal stability, can not be used in injection molding, easy decomposition of chlorides, etc., to achieve good performance and appearance, reduce the use of The effect of not decomposing quantity and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 High flame retardant grade modified material

[0023] Formula: AS resin 60kg; neoprene CR122 30kg; decabromodiphenylethane 8kg, antimony trioxide 4kg, lubricant EBS 0.5kg; environment-friendly compound stabilizer 1.5kg; antioxidant (1010) 0.1kg ; Antioxidant (168) 0.2kg; Toughening agent MABS2628 5kg.

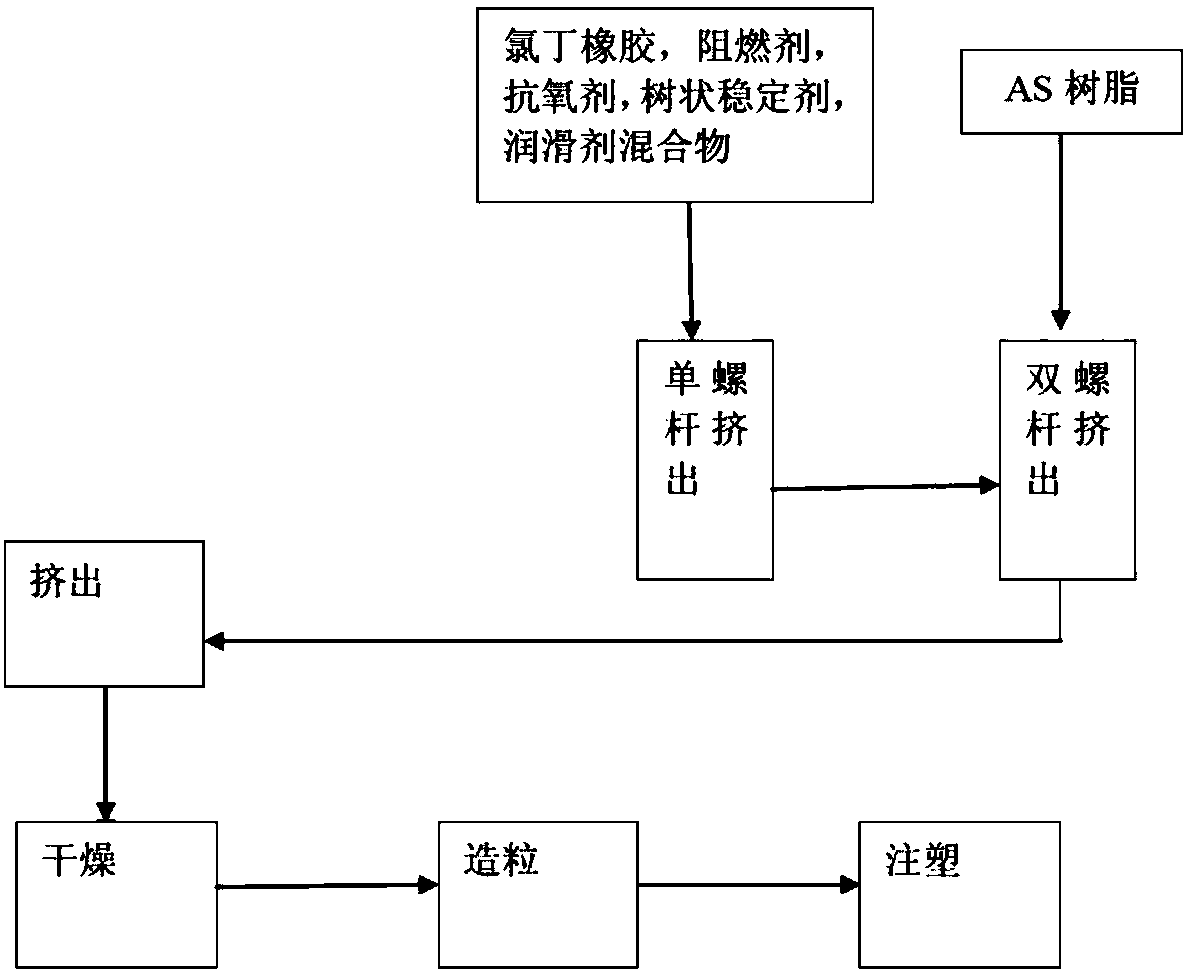

[0024] Mix the above-mentioned neoprene CR122 with decabromodiphenylethane, antimony trioxide, lubricant, heat stabilizer, all antioxidants and tougheners in a high-mixing pot at 600rpm at room temperature for 5 minutes, then transfer to the two-stage Plasticize in the single-screw of the extruder, plasticize the AS resin through the twin-screw, fully blend and plasticize in the middle of the twin-screw, and dry the extruded material in a blower drying oven at 90°C for 2-4 hours, and then injection molding to prepare test samples strip. The preparation process is as figure 1 shown.

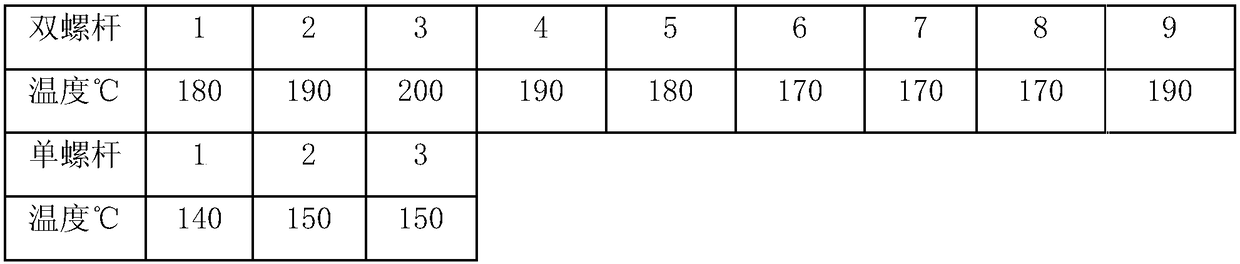

[0025] The extrusion process parameter of table 1 embodiment 1

[0026...

Embodiment 2

[0027] Embodiment 2 high flow grade flame retardant material

[0028] Formula: AS resin 55kg; Neoprene 232 30kg; tetrabromobisphenol A10kg, antimony trioxide 4.5kg, lubricant EBS 0.5kg; environment-friendly compound special stabilizer 2.5kg; antioxidant (1010) 0.1kg; Antioxidant (168) 0.2kg; toughening agent MABS2628 5kg.

[0029] Mix the above-mentioned chloroprene rubber 232 with tetrabromobisphenol A, antimony trioxide, lubricant, environment-friendly composite stabilizer, all antioxidants and toughening agents in a high mixing pot at 600rpm at room temperature for 5 minutes, then transfer Plasticize in the single screw of the two-stage extruder, AS is plasticized by the twin screw, fully blended and plasticized in the middle of the twin screw, and the extruded material is dried in a blower drying oven at 90°C for 2-4 hours, and then prepared by injection molding Test splines.

[0030] The extrusion process parameter of table 2 embodiment 2

[0031]

Embodiment 3

[0032] Example 3 High impact flame retardant material

[0033] Formula: AS resin 65kg; neoprene CR2441 25kg; bromotriazine 10kg, antimony trioxide 4.5kg, lubricant 0.5kg; environment-friendly compound stabilizer 3kg; antioxidant (1010) 0.1kg; antioxidant Agent (168) 0.2kg; Toughening agent MABS2628 5kg.

[0034] Mix the above-mentioned chloroprene rubber with bromotriazine, antimony trioxide, lubricant, environment-friendly composite special stabilizer, all antioxidants and toughening agents in a high mixing pot at 600rmp room temperature for 5 minutes, then transfer to double The AS is plasticized in the single-screw of the extruder, and the AS is plasticized by the twin-screw, fully blended and plasticized in the middle of the twin-screw, and the extruded material is dried in a blower drying oven at 90°C for 2-4 hours, and then injection-molded to prepare the test sample strip.

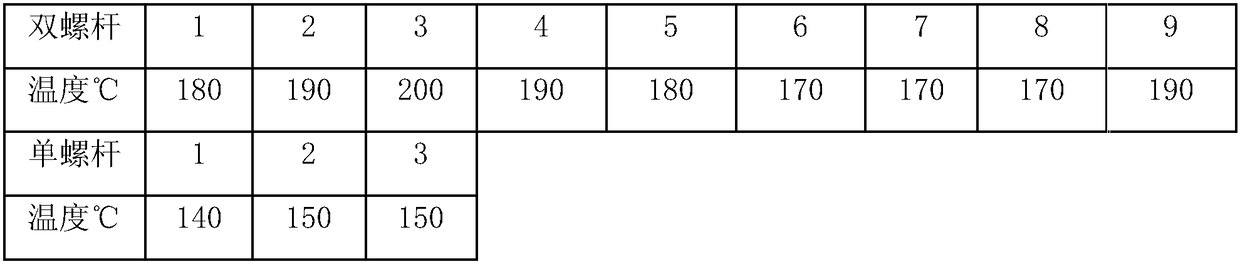

[0035] The extrusion process parameter of table 3 embodiment 3

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com