Sericite composite used in transparent plastic master batch and preparation method

A composite material and sericite technology, which is applied in the field of filler modification, can solve the problems of poor UV resistance, low transparency, and unsatisfactory effects, etc., to achieve improved UV resistance, easy to obtain raw materials, and overcome natural grayish white color that is not easy to change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

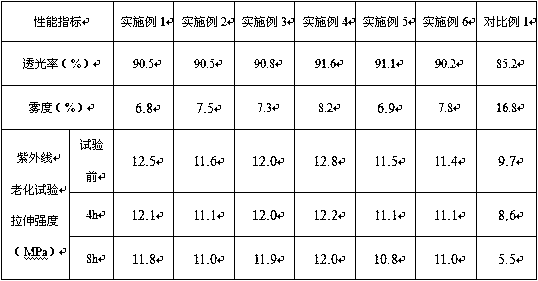

Examples

Embodiment 1

[0031] (1) Alkaline washing is performed on the sericite first, then pickling is performed, and then washed with clean water to obtain pretreated sericite; sodium phosphate solution is used for alkali washing; sulfuric acid solution is used for pickling;

[0032] (2) Grind the sericite pretreated in step (1) into superfine flaky powder, and then add it into water to make sericite slurry; the average particle size of the superfine flaky powder is 6 μm; the sericite slurry In the material, by weight, wherein: 36 parts of sericite, 64 parts of water;

[0033] (3) First prepare a zinc sulfate solution with a mass concentration of 44%, then add an oxalic acid complexing agent, and then adjust the pH value to 8 with ammonia water to obtain a zinc oxalate complex solution; in the zinc oxalate complex solution, by weight , wherein: 70 parts of zinc sulfate solution, 29 parts of oxalic acid complexing agent, 1 part of ammonia water;

[0034] (4) Add the zinc oxalate complex solution p...

Embodiment 2

[0037] (1) Alkaline washing is first performed on the sericite, then pickling, and then washed with water to obtain pretreated sericite; sodium carbonate solution is used for alkali washing; hydrochloric acid solution is used for pickling;

[0038] (2) Grind the sericite pretreated in step (1) into superfine flaky powder, and then add it into water to make sericite slurry; the average particle size of the superfine flaky powder is 3 μm; the sericite slurry In the material, by weight, wherein: 30 parts of sericite, 70 parts of water;

[0039] (3) First prepare a zinc sulfate solution with a mass concentration of 40%, then add an oxalic acid complexing agent, and then adjust the pH value to 8.5 with ammonia water to obtain a zinc oxalate complex solution; in the zinc oxalate complex solution, by weight , wherein: 71 parts of zinc sulfate solution, 28 parts of oxalic acid complexing agent, 1 part of ammonia water;

[0040](4) Add the zinc oxalate complex solution prepared in ste...

Embodiment 3

[0043] (1) The sericite is firstly washed with alkali, then pickled, and then washed with clean water to obtain pretreated sericite; the alkali wash uses sodium hydroxide solution; the pickle uses hydrofluoric acid solution;

[0044] (2) Grind the sericite pretreated in step (1) into superfine flaky powder, then add it into water to make sericite slurry; the average particle size of the superfine flaky powder is 10 μm; sericite slurry In the material, by weight, wherein: 40 parts of sericite, 60 parts of water;

[0045] (3) First prepare a zinc sulfate solution with a mass concentration of 50%, then add an oxalic acid complexing agent, and then adjust the pH value to 8 with ammonia water to obtain a zinc oxalate complex solution; in the zinc oxalate complex solution, the , wherein: 66 parts of zinc sulfate solution, 32 parts of oxalic acid complexing agent, 2 parts of ammonia water;

[0046] (4) Add the zinc oxalate complex solution prepared in step (3) into the sericite slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com