Water-cooled heat sink for modular series connection type high-voltage frequency converter

A high-voltage inverter and series-type technology, which is applied in cooling/ventilation/heating transformation, electric solid-state devices, semiconductor devices, etc., can solve the problem that the withstand voltage of the device cannot meet the technical performance requirements, and the effective insulation of the power module cannot be guaranteed. High withstand voltage and other problems, to achieve the effect of compact structure, good insulation, and improved insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

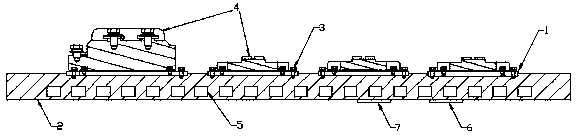

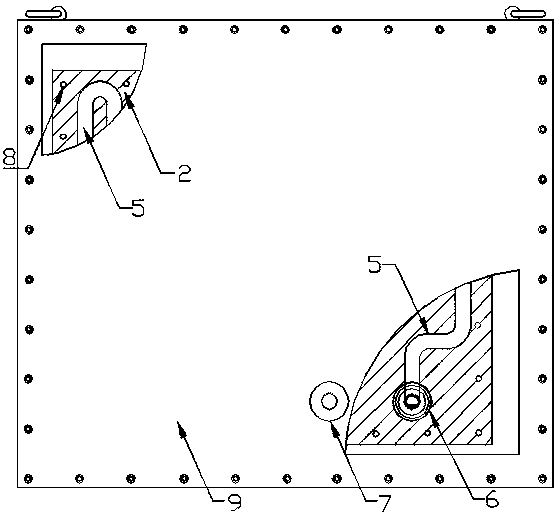

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a water-cooled radiator of a module series high-voltage inverter, including a module series high-voltage inverter body, the main circuit of the module series high-voltage inverter body adopts a low-voltage power module 4 series voltage division topology, and the A water-cooled radiator is installed in the body of the module series high-voltage inverter. The water-cooled radiator is mainly composed of a plurality of independent heat-dissipating substrates 1 and a water-cooled plate 2 embedded with a water channel 5. The material of the water-cooled plate 2 is A new type of insulating and heat-conducting material, the back of the water-cooling plate 2 has water inlet and outlet 7 and installation holes 8, and the water-cooling plate 2 and the inverter shell are fastened and connected by bolts 3; the heat dissipation substrate 1 is a plurality of independ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com