Method for preparing size-controllable easily-peelable layered nanometer zirconium phosphate

A layered nanotechnology, easy-to-peel technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high crystallinity, complex process, poor effect, etc., to achieve easy process control, simple preparation process, Overcome difficult peeling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

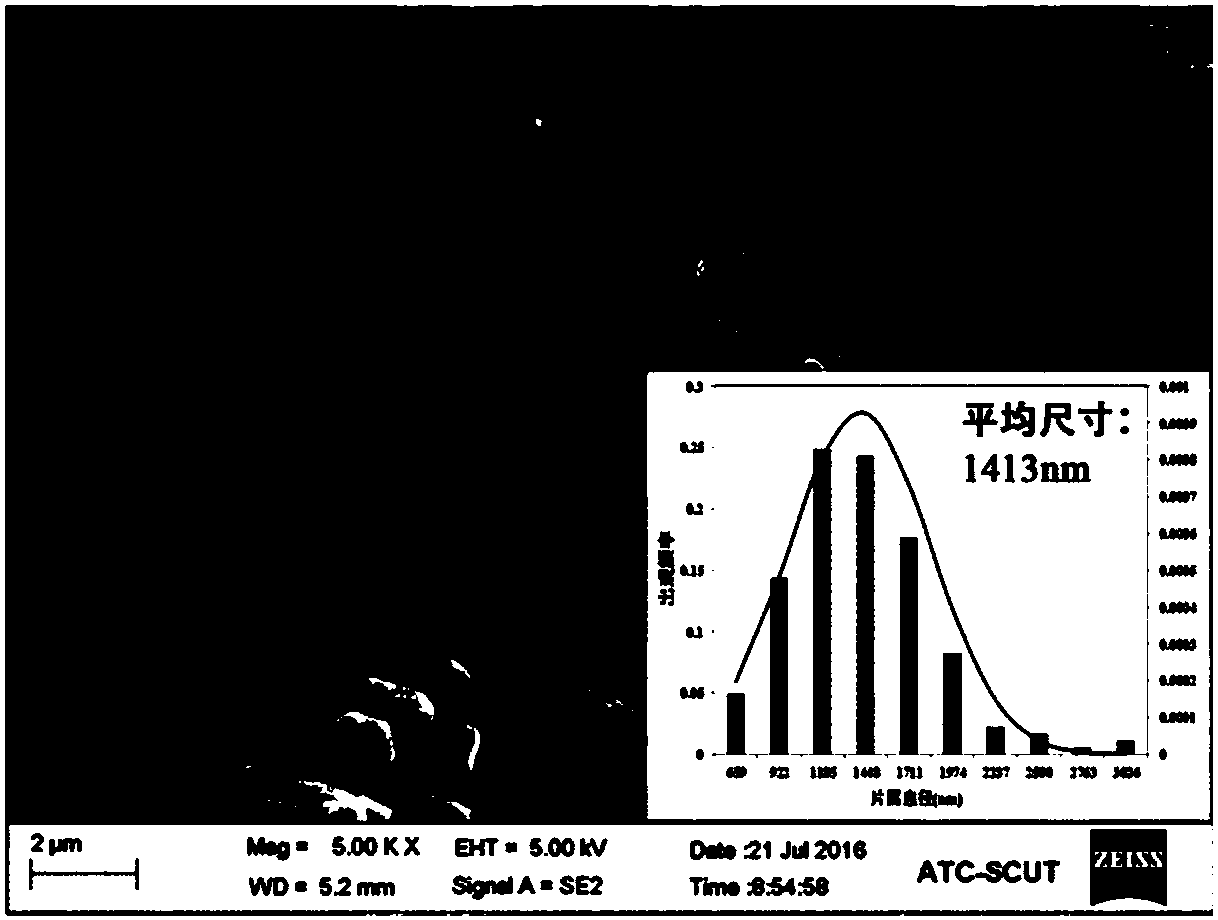

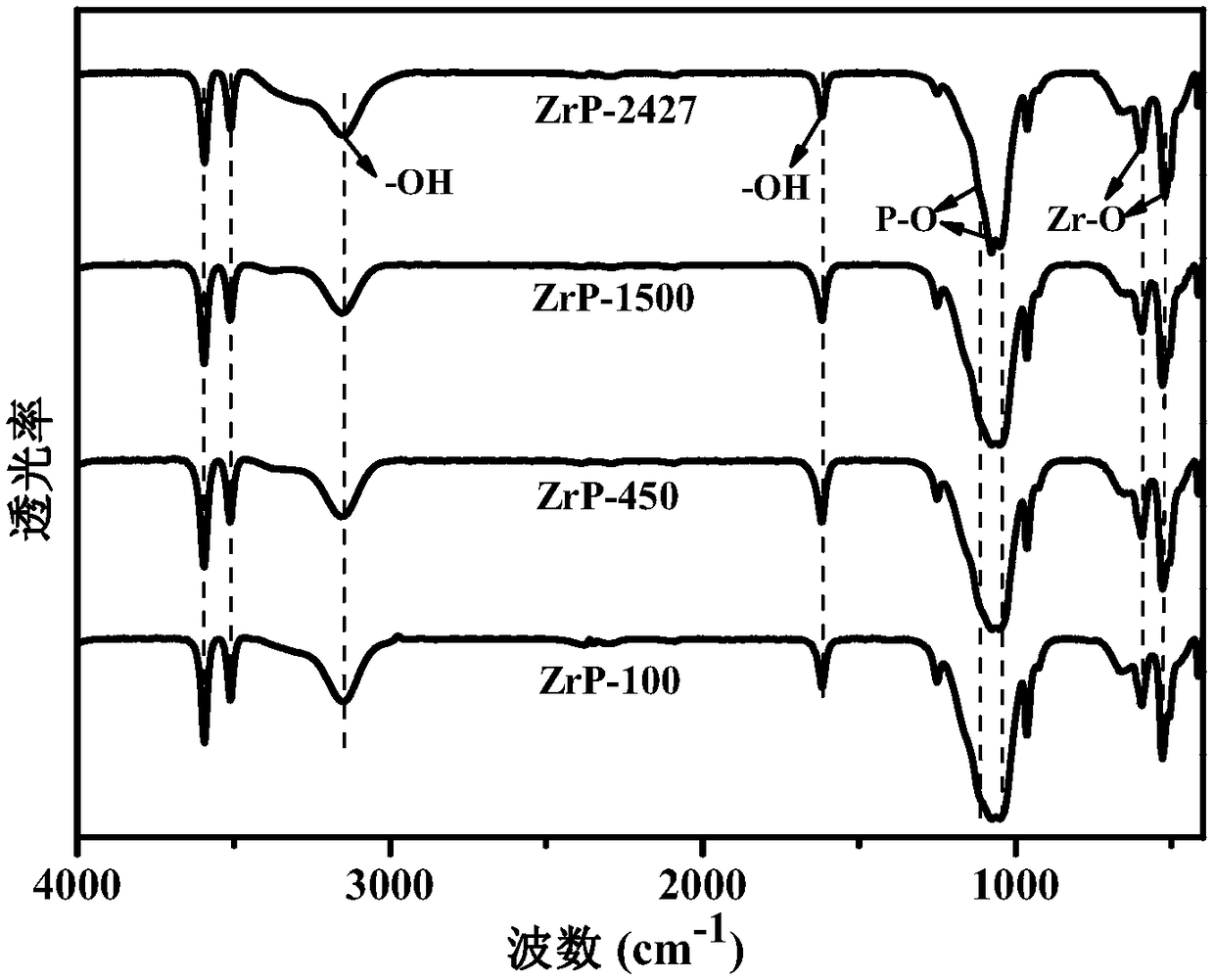

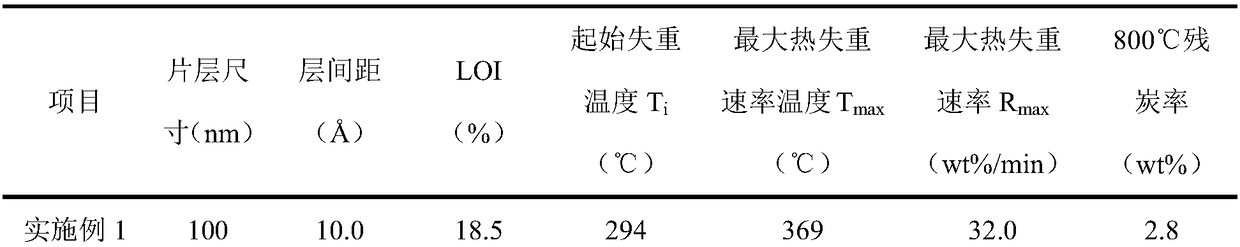

[0034]Prepare 60 mL of concentrated phosphoric acid with a concentration of 3 mol / L, add 6.00 g of zirconium oxychloride, 6.00 g of methylamine, and 0.20 g of sodium dodecylbenzenesulfonate, and mechanically stir at a speed of 300 r / min for 20 min to fully disperse it. Then the mixed solution was poured into a hydrothermal reaction kettle (100 mL), and reacted at 200° C. for 3 h. After the reaction, the mixed solution was naturally cooled to room temperature. Pour off the supernatant, and centrifuge the milky white precipitate in the lower layer (10000r / min, 10min) to separate the solid from the liquid. The obtained solid product is washed with an appropriate amount of deionized water, and then centrifuged. Repeat the above centrifugation treatment and deionized water washing steps 4 times to make the pH of the centrifuged supernatant ≥ 5. The washed solid product was dried in an oven at 80°C for 12 hours, and then observed by scanning electron microscope, X-ray diffraction a...

Embodiment 2

[0037] Prepare 60 mL of concentrated phosphoric acid with a concentration of 6 mol / L, add 6.00 g of zirconium sulfate, 6.00 g of ethylenediamine, and 0.20 g of sodium dodecylbenzenesulfonate, stir mechanically at a speed of 500 r / min for 20 min to fully disperse it, and then The mixed solution was poured into a hydrothermal reaction kettle (100 mL), and reacted at 150° C. for 12 h. After the reaction, the mixed solution was naturally cooled to room temperature. Pour off the supernatant, and centrifuge the milky white precipitate in the lower layer (10000r / min, 10min) to separate the solid from the liquid. The obtained solid product is washed with an appropriate amount of deionized water, and then centrifuged. Repeat the above centrifugation treatment and deionized water washing steps 3 times to make the pH of the centrifuged supernatant ≥ 5. The washed solid product was dried in an oven at 80°C for 12 hours, and then subjected to scanning electron microscope observation, X-ra...

Embodiment 3

[0040] Prepare 75mL of concentrated phosphoric acid with a concentration of 3mol / L, add 10.00g of zirconium carbonate, 7.50g of ethylenediamine, and 0.75g of octadecyltrimethylammonium bromide, and mechanically stir for 30min at a speed of 300r / min to fully disperse , and then the mixed solution was poured into a hydrothermal reactor (100 mL), and reacted at 250° C. for 36 h. After the reaction, the mixed solution was naturally cooled to room temperature. Pour off the supernatant, and centrifuge the milky white precipitate in the lower layer (10000r / min, 10min) to separate the solid from the liquid. The obtained solid product is washed with an appropriate amount of deionized water, and then centrifuged. Repeat the above centrifugation treatment and deionized water washing steps 4 times to make the pH of the centrifuged supernatant ≥ 5. The washed solid product was dried in an oven at 80°C for 12 hours, and then subjected to scanning electron microscope observation, X-ray diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com