Solvothermal Synthesis of fto Conductive Materials

A technology of conductive materials and synthesis methods, applied in chemical instruments and methods, other chemical processes, tin oxide, etc., to achieve good application prospects, enrich surface hydroxyl groups, and avoid high-temperature treatment processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

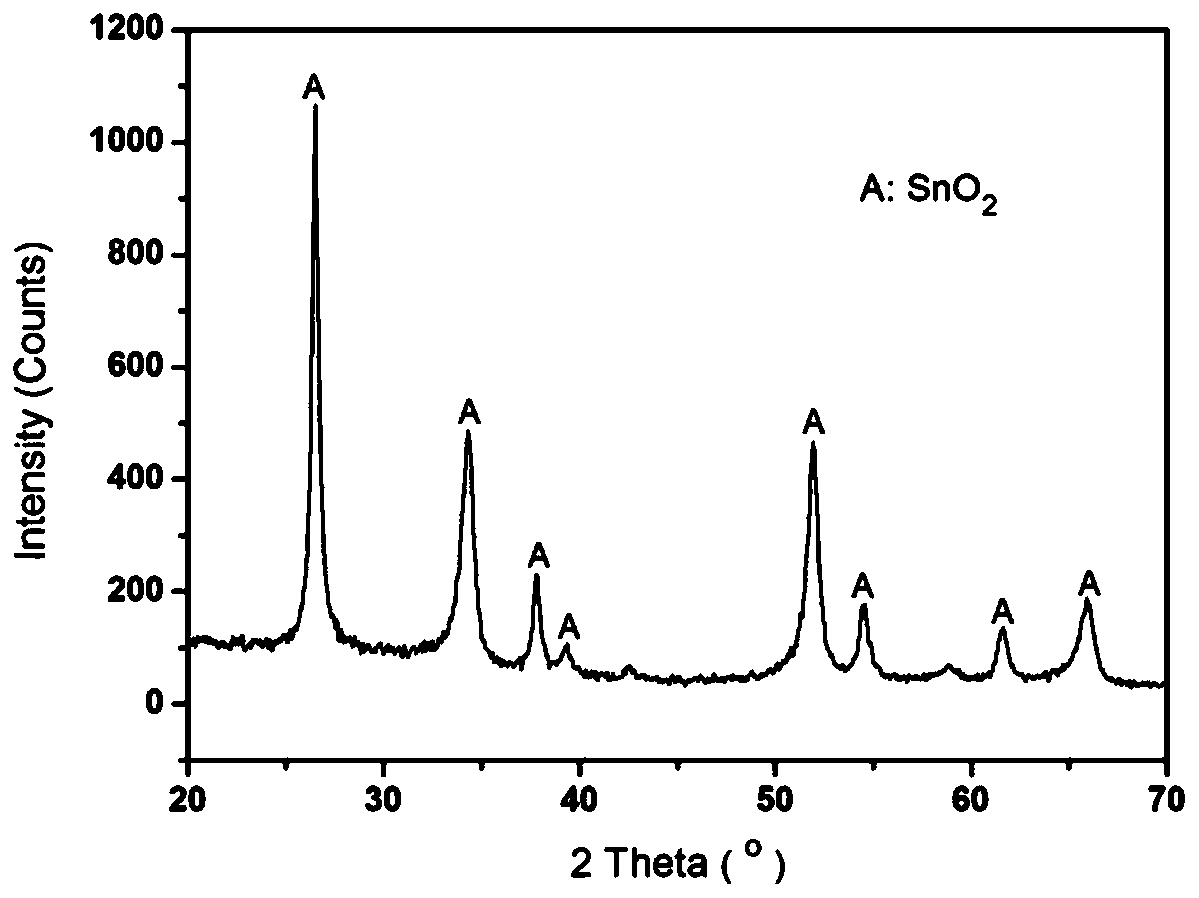

Embodiment 1

[0024] In this example, first dissolve 6g of tin tetrachloride pentahydrate in 80mL of absolute ethanol, then add 10mL of hydrogen peroxide (27.5wt.%) and 5mL of hydrofluoric acid (40wt.%) to prepare a solvothermal mother liquor; take 80 Add 10g of the target metal tin powder (99wt.%) to the solvothermal mother liquor, stir for 3 minutes and transfer all the materials into a polytetrafluoroethylene-lined stainless steel reaction kettle with a volume of 200mL, and first react at 100°C for 8 Hours, fully oxidize metal tin and introduce fluorine ions, and then solvothermal reaction at 180 ° C for 16 hours to convert fluorine-containing tin hydroxide or amorphous tin dioxide into highly crystallized fluorine-doped tin dioxide; solvothermal After the reaction was completed, the reactant was cooled to room temperature, washed three times with deionized water, and then dried at 120°C to obtain the FTO conductive material.

Embodiment 2

[0026] In this example, the electrical conductivity of the material prepared in Example 1 was evaluated by voltammetry. Grind the FTO conductive material into powder first, then weigh 0.7g of the powder, add it to a circular mold with a diameter of 1.5cm, and press it into a thin slice. Clamp it in the middle and press it tightly, then use a high-precision programmable DC power supply to apply a voltage of 3V between the two copper plates, and measure the current at the same time.

[0027] The above method was used to test the conductivity of the FTO prepared by 450°C roasting, the FTO prepared by 140°C solvothermal and the FTO prepared by 180°C solvothermal (Example 1), and the measured currents were 55mA, 1.2mA and 38mA respectively. It can be seen that the conductivity of the FTO material prepared by 180 ℃ solvothermal is close to that of the sample baked at 450 ℃, while the FTO material prepared by 140 ℃ solvothermal is almost non-conductive, indicating that the solvotherm...

Embodiment 3

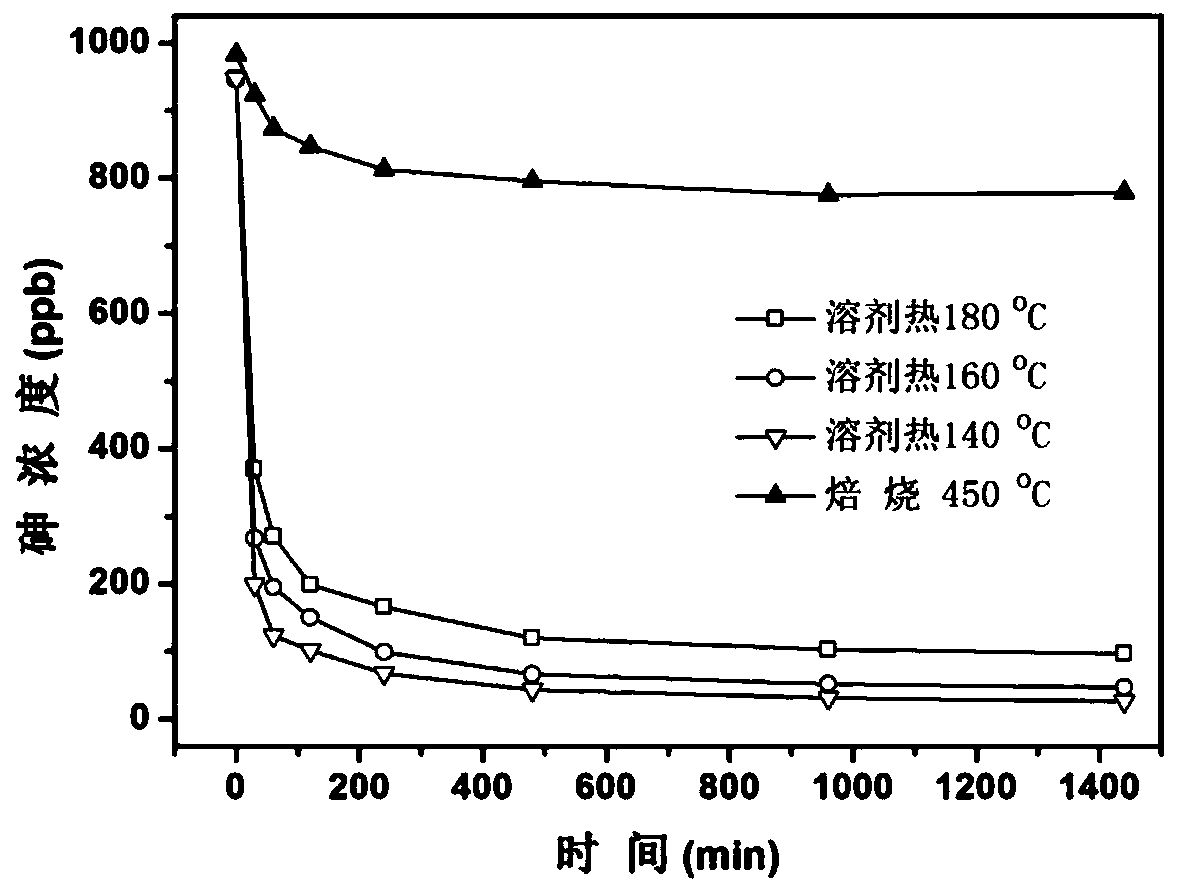

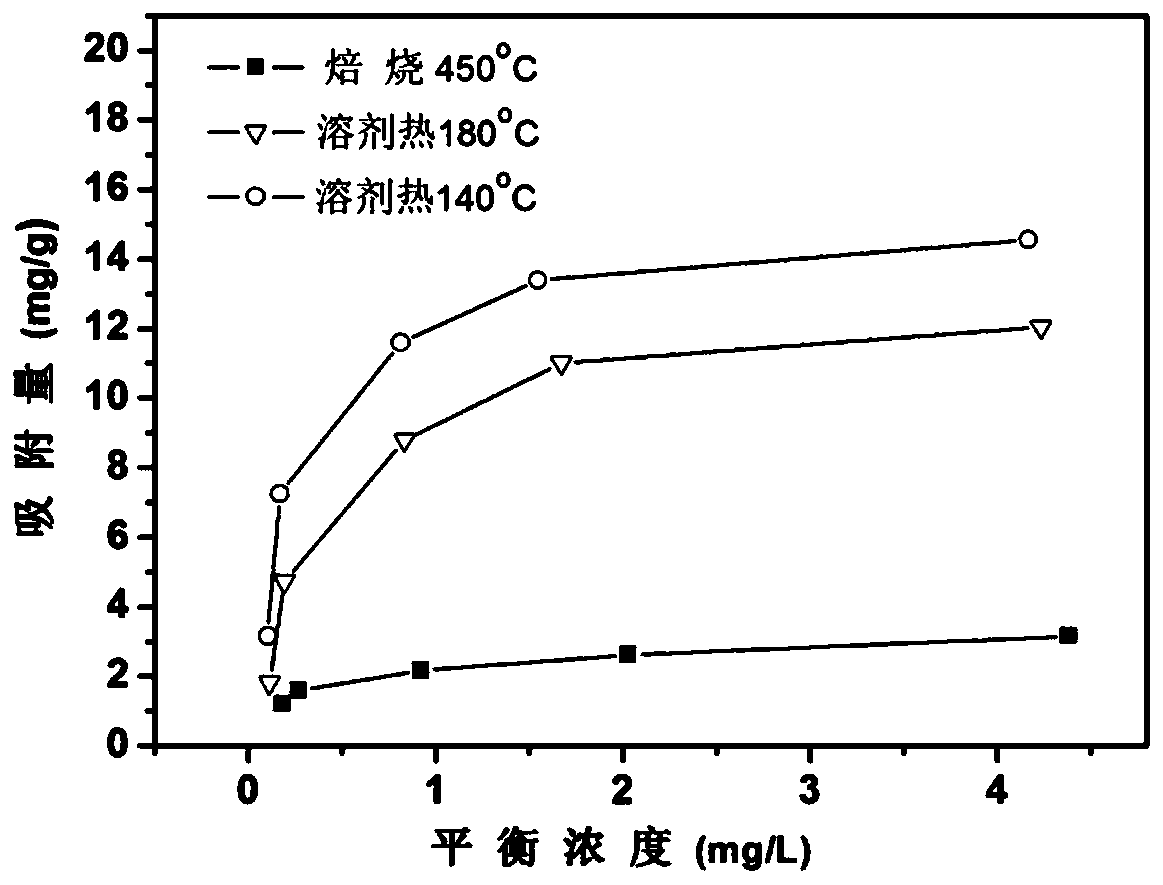

[0029] In this example, the FTO conductive material synthesized by solvothermal synthesis (solvothermal temperature 140°C, 160°C and 180°C) and the FTO conductive material synthesized by calcination method (calcination temperature 450°C) were used as adsorbents respectively. Arsenic is adsorbed, and the kinetic curve of arsenic adsorption is determined. The arsenic concentration in the raw water was 947ppb, and the amount of the material was 0.5g / L. After the material was added to the arsenic solution, the stirring was continued and samples were taken at different times to measure the arsenic concentration. After 480 minutes of reaction, the adsorption of arsenic by all materials reached equilibrium, and after 960 minutes, the adsorption of arsenic by all materials reached equilibrium ( figure 2 ), wherein the arsenic equilibrium concentration corresponding to the roasting synthetic material is 774.7ppb, and the arsenic equilibrium concentration corresponding to the solvother...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com