Hydroxyapatite ceramic/graphene composite bone tissue replacement material and its preparation

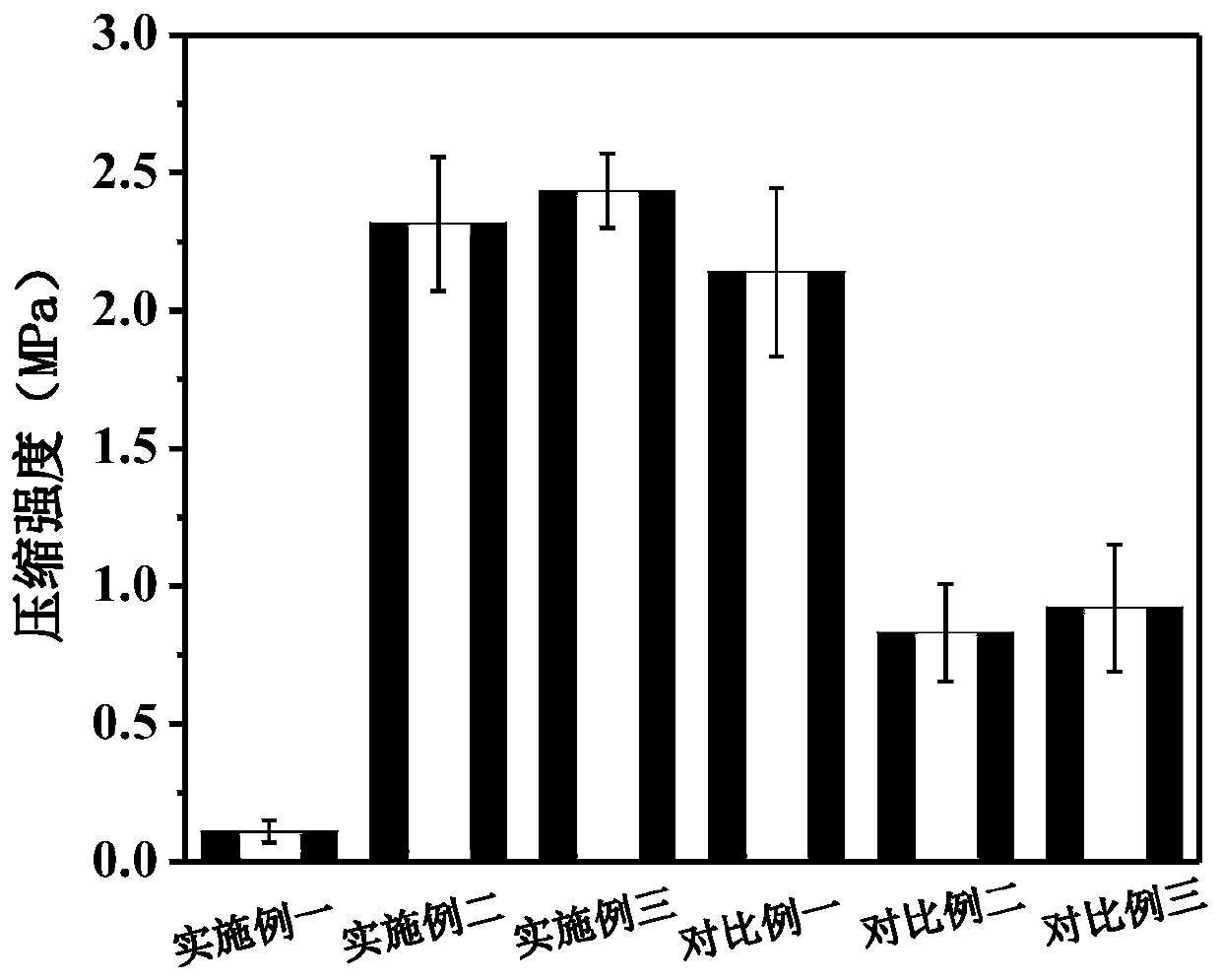

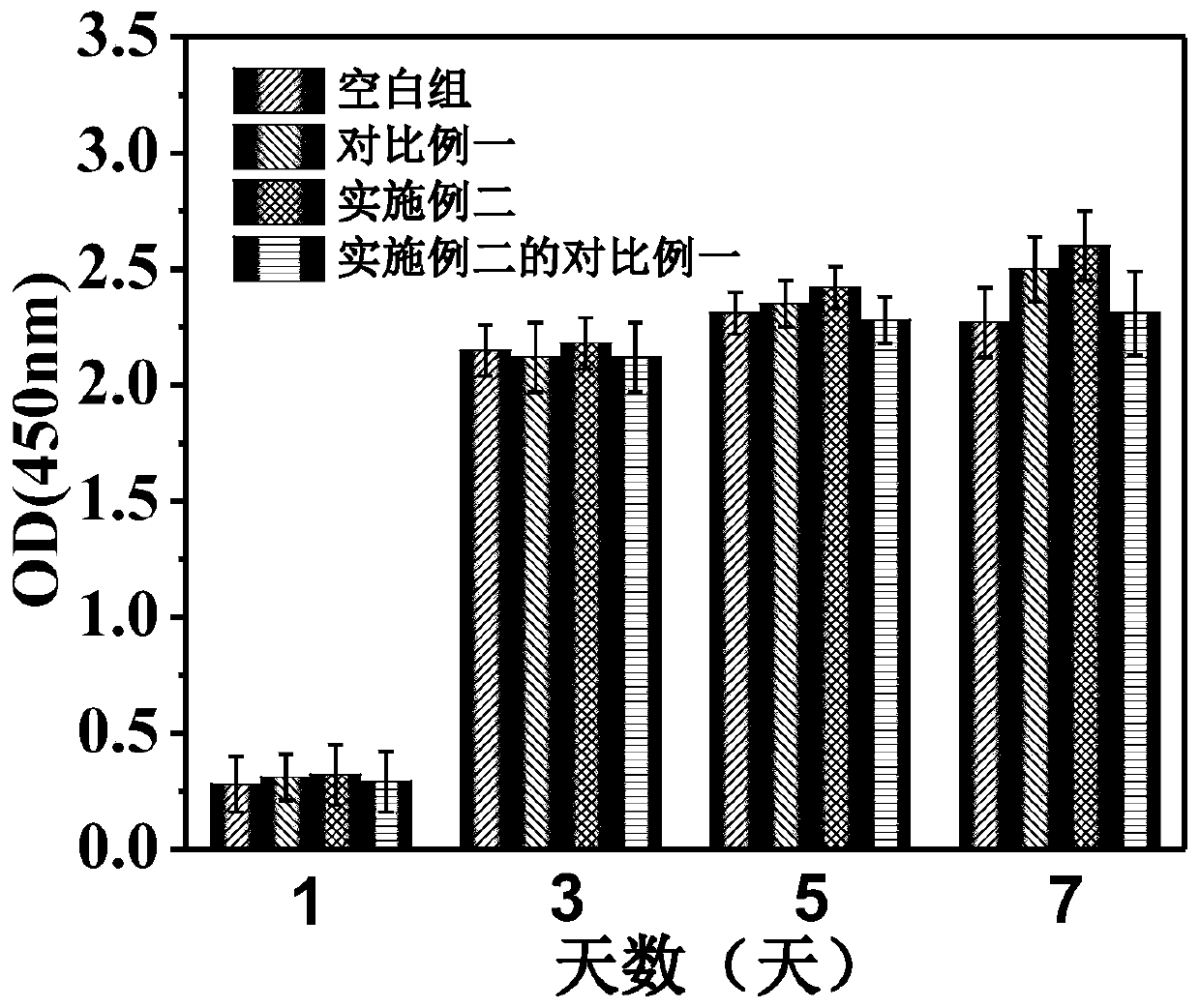

A composite technology of hydroxyapatite and graphene, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of complex preparation process, high production cost, and low porosity, and achieve high porosity, high Mechanical strength, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The first technical problem to be solved by the present invention is to provide a preparation method of hydroxyapatite ceramic / graphene composite bone tissue replacement material, the preparation method comprising the following steps:

[0027] (1) Preparation of hydroxyapatite / chitosan / graphene slurry: disperse the nano-hydroxyapatite powder in the graphene dispersion, ultrasonically treat the nano-hydroxyapatite to disperse evenly (1h after ultrasonic treatment) Acetic acid, add chitosan powder while stirring, and then stir and mix (generally need to stir for 2h) to get hydroxyapatite / chitosan / graphene slurry; wherein, nano-hydroxyapatite, chitosan and graphene The mass ratio is: 20-80 parts by weight of nano-hydroxyapatite, 0.5-4 parts by weight of chitosan, and 0.05-1 part by weight of graphene;

[0028] (2) Preparation of porous hydroxyapatite composite scaffold: immerse the polyurethane sponge in the hydroxyapatite / chitosan / graphene slurry obtained in step (1) and ...

Embodiment 1

[0035] (1) Preparation of CS / GO / HA slurry: Disperse 3g of HA nanopowder in 10ml of 0.1wt% GO solution, add 0.2ml of acetic acid after ultrasonication for 1h (the purpose of adding acetic acid is to dissolve chitosan) , after magnetic stirring for 10 min, 0.3 g of CS powder was added and stirred for 2 h to obtain CS / GO / HA slurry.

[0036] (2) Preparation of PU with different shapes: Cut the purchased melamine sponge into a cuboid of 3mm×3mm×5mm with a blade.

[0037] (3) Preparation of porous hydroxyapatite composite scaffold: immerse the block-shaped PU sponge obtained in (2) in the slurry in (1) and suck the slurry into the sponge by squeezing the melamine sponge, and then place it on the The porous hydroxyapatite composite scaffold was prepared by drying in a vacuum oven at 60 degrees under the condition of a vacuum degree of 80 kPa.

[0038] (4) Preparation of porous hydroxyapatite composite ceramics: the dry porous hydroxyapatite composite scaffold obtained in (3) was pla...

Embodiment 2

[0040] (1) Preparation of CS / GO / HA slurry: disperse 6g of HA nanopowder in 10ml of 0.1wt% GO solution, add 0.2ml of acetic acid after ultrasonication for 1h, add 0.3g of CS powder after magnetic stirring for 10min and stir again 2h, the CS / GO / HA slurry was obtained.

[0041] (2) Preparation of PU with different shapes: Cut the purchased melamine sponge into a cuboid of 3mm×3mm×5mm with a blade.

[0042] (3) Preparation of porous hydroxyapatite composite scaffold: immerse the block-shaped PU sponge obtained in (2) in the slurry in (1) and suck the slurry into the sponge by squeezing the melamine sponge, and then place it on the The porous hydroxyapatite composite scaffold was prepared by drying in a vacuum oven at 60 degrees under the condition of a vacuum degree of 80 kPa.

[0043] (4) Preparation of porous hydroxyapatite composite ceramics: put the dried porous hydroxyapatite composite scaffold obtained in (3) into a crucible and sinter it under the protection of nitrogen. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com