Oxidation type biodegradable biaxially-stretchable bio-based nylon film and preparation method thereof

A bio-based nylon, two-way stretching technology, applied in the direction of chemical instruments and methods, types of packaging items, special packaging items, etc., to achieve excellent biodegradability, reduce consumption, and broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

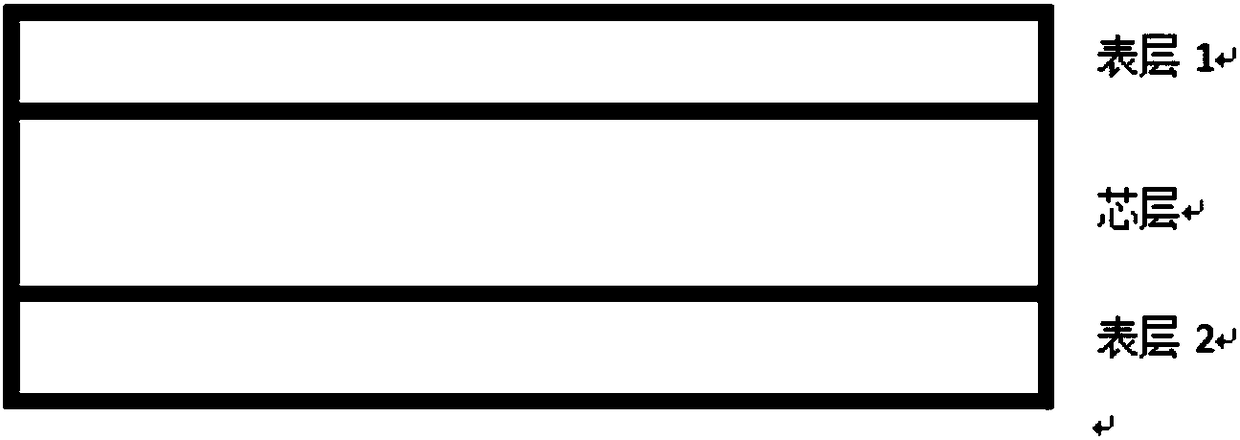

[0030] The preparation method of the above-mentioned oxidative biodegradable biaxially stretched bio-based nylon film comprises the following steps:

[0031] (1) each component in the surface layer 1, the core layer and the surface layer 2 is mixed in proportion, and dispersed uniformly by a high-speed mixer;

[0032] (2) The raw materials of the surface layer 1, the core layer and the surface layer 2 are melted and co-extruded in three extruders in proportion, and the melt is cast through a T-shaped die to a surface temperature of 15 to 35°C. Chilled roll quenched cast sheet;

[0033] (3) The unstretched cast sheet is subjected to a humidity-conditioning treatment for about 1 minute in a water tank at 40-70°C. The surface of the cast sheet after humidity-conditioning is dried with an air knife to dry the residual moisture on the surface, and a magnetic levitation linear motor is used to synchronize Stretching technology carries out horizontal and vertical simultaneous stretchi...

Embodiment 1

[0036] In this example, the top layer 1 is bonded with 98.75% bio-based nylon 56, 0.5% oxo-biodegradant, 0.2% silica, 0.1% erucamide, 0.15% diffusing oil, 0.3% glycidyl methacrylate Branched ethylene-octene block copolymer; core layer is made of 99.05% bio-based nylon 56, 0.5% oxygenated biodegradant, 0.15% diffusing oil, 0.3% glycidyl methacrylate grafted ethylene-octene block Copolymer composition; skin 2 consists of 98.75% bio-based nylon 56, 0.5% oxo-biodegradant, 0.2% silica, 0.1% erucamide, 0.15% diffusing oil, 0.3% glycidyl methacrylate grafted ethylene - Composition of octene block copolymers.

[0037] Wherein, the oxygen-containing biodegradation agent is the following mixture: pentose sugar: plant cellulose: cerium-containing metal salt: polylactic acid=1:1:1:1.

[0038] The sample was prepared according to the aforementioned preparation method, and the total thickness of the obtained film was 15 μm, and the thickness of the core layer was 12 μm.

example 2

[0040] In this example, the top layer 1 is bonded with 98.25% bio-based nylon 56, 1% oxo-biodegradant, 0.2% silica, 0.1% erucamide, 0.15% diffusing oil, 0.3% glycidyl methacrylate Branched ethylene-octene block copolymer; core layer is made of 98.55% bio-based nylon 56, 1% oxygenated biodegradant, 0.15% diffusing oil, 0.3% glycidyl methacrylate grafted ethylene-octene block Copolymer composition; skin 2 is composed of 98.25% bio-based nylon 56, 1% oxygen biodegradant, 0.2% silica, 0.1% erucamide, 0.15% diffusing oil, 0.3% glycidyl methacrylate grafted ethylene - Composition of octene block copolymers.

[0041] Wherein, the oxygen-containing biodegradation agent is the following mixture: pentose sugar: plant cellulose: cobalt-containing metal salt: polylactic acid=0.5:1:1:1.

[0042] The sample was prepared according to the aforementioned preparation method, and the total thickness of the obtained film was 15 μm, and the thickness of the core layer was 12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com