A kind of sound insulation and noise reduction, flame retardant polypropylene material and preparation method thereof

A technology of flame-retardant polypropylene and polypropylene materials, applied in the fields of flame-retardant polypropylene materials and their preparation, sound insulation and noise reduction, can solve the problems of easily generating dust, harming the environment and human health, reducing the mechanical properties of materials, etc., and achieving good Sound and noise reduction performance, improve flame retardant efficiency, improve the effect of poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

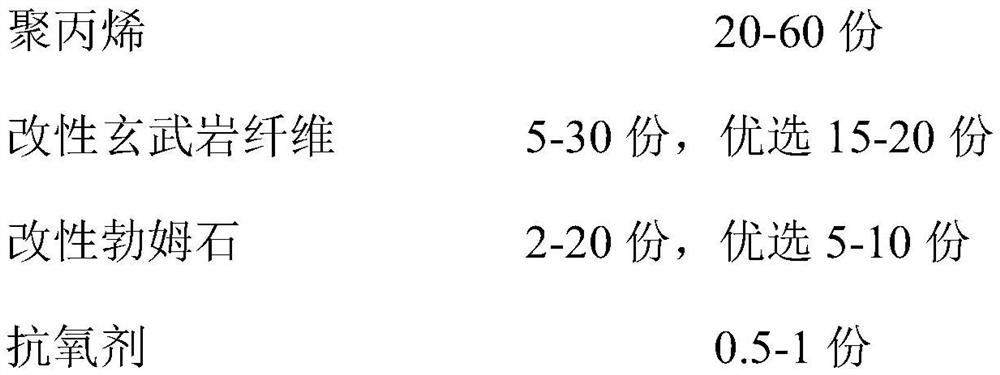

Method used

Image

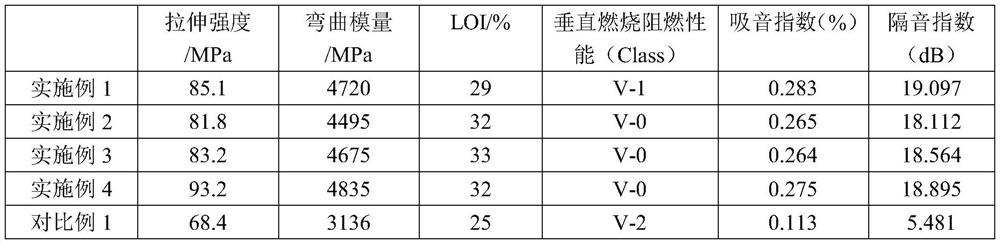

Examples

Embodiment 1

[0035] (1) Preparation of modified basalt fiber

[0036] a. Soak the basalt fiber in a 5wt% NaOH solution with a bath ratio of 1:50 for 90 minutes, and then soak it in a 5wt% acetic acid solution with a bath ratio of 1:50 for 120 minutes before taking it out.

[0037] b. Using ethanol as a solvent, make KH550 (purchased from Guangzhou Yihuisheng Chemical Co., Ltd.) into a 20wt% solution, place the basalt fiber treated in step a in the above solution, the bath ratio is 1:20, soak 3h.

[0038] c. Place the fiber treated above in a 10wt% phosphoric acid solution with a liquor ratio of 1:40 and ultrasonically mix it for 4 hours before taking it out. Put it into a drying oven, heat at 80°C for 60 minutes to remove the solvent, and then react at 110°C for 120 minutes to make the basalt fiber fully react with the above substances.

[0039] (2) Preparation of modified boehmite

[0040] a. Soak the boehmite in an acrylic acid solution with a bath ratio of 1:30 and 10wt% for 60 minut...

Embodiment 2

[0045] (1) Preparation of modified basalt fiber

[0046] a. Soak the basalt fiber in a 20wt% NaOH solution with a bath ratio of 1:20 for 20 minutes, and then soak it in a 20wt% acetic acid solution with a bath ratio of 1:20 for 30 minutes before taking it out.

[0047] b. Using distilled water as a solvent, make KH602 (purchased from Foshan Shengyi Plastic Chemical Co., Ltd.) into a 50wt% solution, place the basalt fiber treated in step a in the above solution, and set the bath ratio to 1:10 , Soak for 1h.

[0048] c. Place the fiber treated above in a 50wt% phosphoric acid solution with a liquor ratio of 1:10 and ultrasonically mix it for 1 hour before taking it out. Put it into a drying oven, heat at 100°C for 10 minutes to remove the solvent, and then react at 130°C for 30 minutes to fully react the basalt fiber with the above substances.

[0049] (2) Preparation of modified boehmite

[0050] a. Soak the boehmite in an acrylic acid solution with a bath ratio of 1:10 and 70...

Embodiment 3

[0055] (1) Preparation of modified basalt fiber

[0056] a. Soak the basalt fiber in a 10wt% NaOH solution with a bath ratio of 1:30 for 50 minutes, and then soak it in a 15wt% acetic acid solution with a bath ratio of 1:30 for 90 minutes before taking it out.

[0057] b. With 50wt% ethanol aqueous solution as solvent, KH602 (purchased from Foshan Shengyi Plastic Chemical Co., Ltd.) is made into a 30wt% solution, and the basalt fiber after step a is placed in the above solution, and the bath ratio is 1:15, soak for 2 hours.

[0058] c. Place the fiber treated above in a bath ratio of 1:25, 30wt% phosphoric acid solution and ultrasonically mix for 2 hours, then take it out. Put it into a drying oven, heat at 90°C for 30 minutes to remove the solvent, and then react at 120°C for 90 minutes to fully react the basalt fiber with the above substances.

[0059] (2) Preparation of modified boehmite

[0060] a. Soak the boehmite in an acrylic acid solution with a bath ratio of 1:20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com