Refrigerant cooling system with high temperature stability

A cooling system and stability technology, applied in the field of heat exchange, can solve the problems of high latent heat value of evaporation phase change, loss of thermal buffer function, slow response and stability, etc., to achieve sufficient response time, maintain heat dissipation capacity, and maintain temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

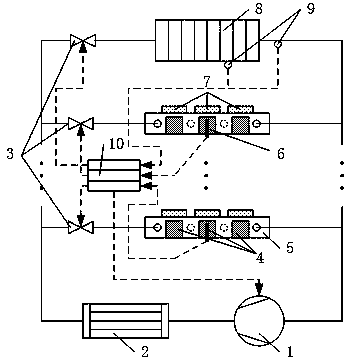

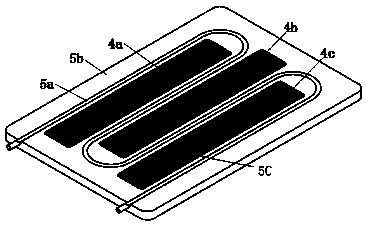

[0035] Such as Figure 1~2 As shown, a high-temperature-stable refrigerant cooling system includes an inverter compressor 1, a condenser 2, and a radiator 5 in contact with a heat generating device 7 connected in sequence, and also includes a phase-change energy storage device located on the radiator 5 Unit 4; phase change energy storage unit 4 includes no less than three high temperature phase change materials 4a, medium temperature phase change materials 4b and low temperature phase change materials 4c with phase change points in different temperature ranges; high temperature phase change materials 4a, medium temperature phase change The material 4b and the low-temperature phase-change material 4c are both non-metallic phase-change materials and are independently installed on the radiator 5; the phase-change temperature of the medium-temperature phase-change material 4b is the working temperature of the radiator 5; the radiator 5 is provided with a refrigerant pipe Road 5a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com