Carbon nitride/alpha iron oxide catalyst, photoelectric auxiliary Fenton system and application thereof to organic wastewater treatment

A catalyst and carbon nitride technology, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of low power generation efficiency, high amplification cost, unfavorable promotion, etc., and achieve low metal dissolution , reduce energy consumption, and accelerate the transmission of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A carbon nitride / α-type iron oxide catalyst, its preparation method comprises the steps:

[0043] 1) 2.0g Fe(NO 3 ) 3 9H 2 O was dissolved in 100mL of N,N-dimethylformamide, then 5.0g of melamine was added, and stirred evenly to obtain a mixed solution;

[0044] 2) Put the obtained mixed solution in an oven and dry at 80°C for 24 hours, then transfer the dried sample into a 50mL porcelain crucible, cover it and place it in a muffle furnace, and raise the temperature to 520°C at a rate of 3°C / min And keep it warm for 2 hours. After the temperature in the furnace drops to room temperature, take it out and crush it through a 200-mesh sieve to obtain a carbon nitride / α-type iron oxide catalyst (referred to as CNFe).

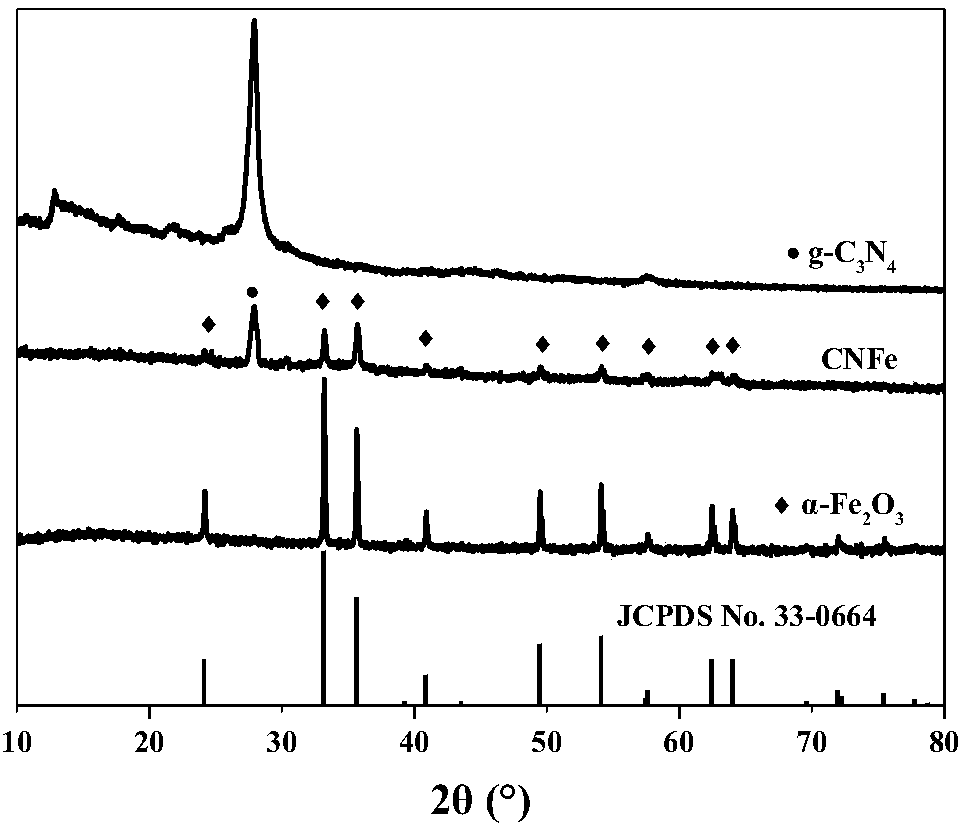

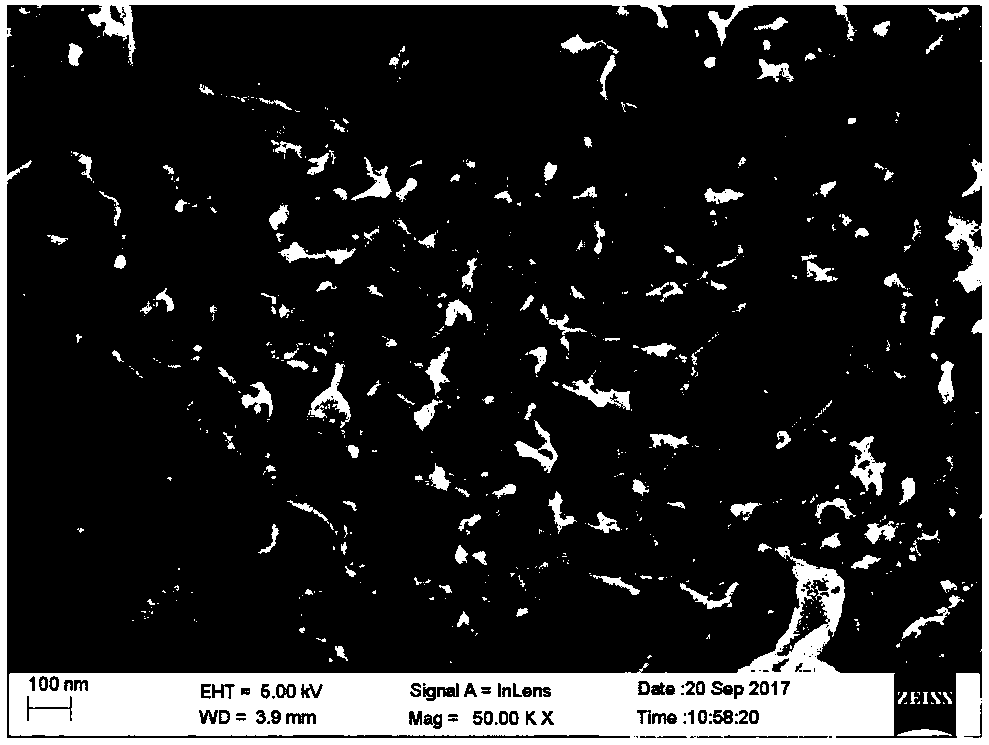

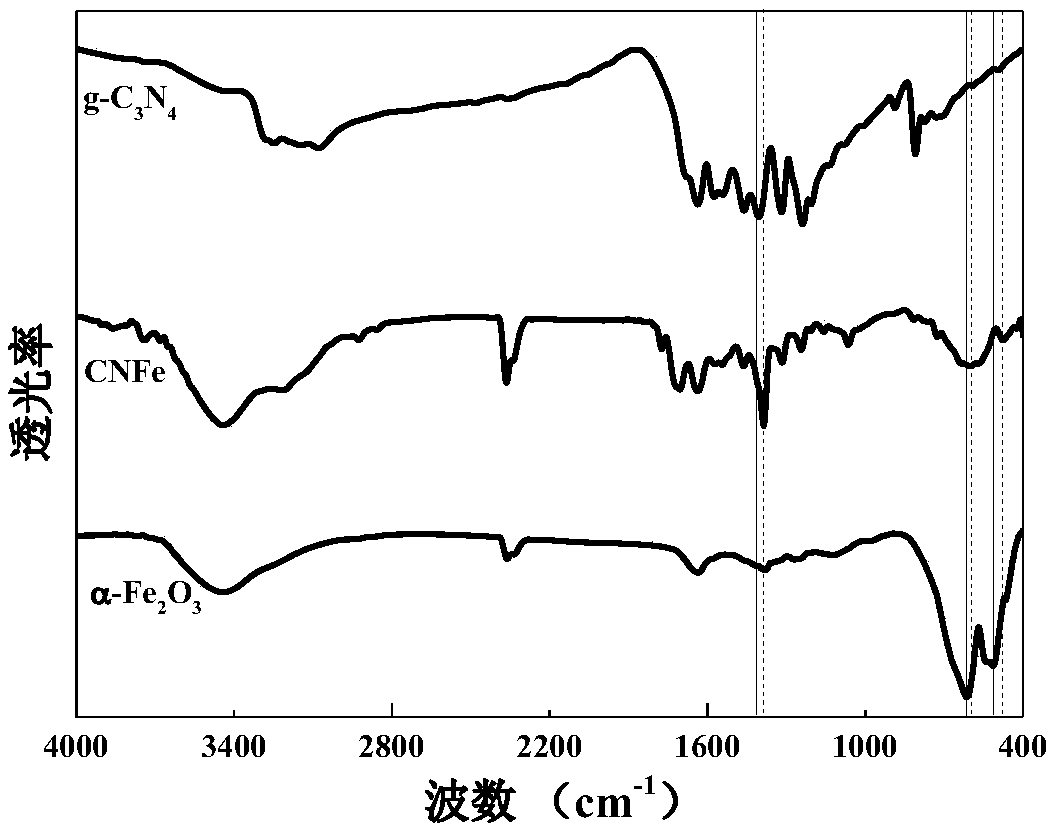

[0045] The product obtained in this embodiment is subjected to X-ray diffraction analysis, field emission scanning electron microscope analysis, Fourier transform infrared spectroscopy analysis and X-ray photoelectron spectroscopy analysis respectively, the...

Embodiment 2

[0047] A carbon nitride / α-type iron oxide catalyst, its preparation method comprises the steps:

[0048] 1) Add 1.0g Fe(NO 3 ) 3 9H 2 O is dissolved in 100mL ethanol, then add 5.0g melamine, stir to obtain a mixed solution;

[0049] 2) Put the obtained mixed solution in an oven to dry at 90°C for 24 hours, then transfer the dried sample into a 50mL porcelain crucible, cover it and place it in a muffle furnace, and raise the temperature to 520°C at a rate of 5°C / min And keep it warm for 4 hours. After the temperature in the furnace drops to room temperature, take it out and crush it through a 200-mesh sieve to obtain a carbon nitride / α-type iron oxide catalyst (denoted as CNFe1).

Embodiment 3

[0051] A carbon nitride / α-type iron oxide catalyst, its preparation method comprises the steps:

[0052] 1) 4.0g Fe(NO 3 ) 3 9H 2 O is dissolved in 100mL ethanol, then add 5.0g melamine, stir to obtain a mixed solution;

[0053] 2) Put the obtained mixed solution in an oven to dry at 60°C for 24 hours, then transfer the dried sample into a 50mL porcelain crucible, cover it and place it in a muffle furnace, and raise the temperature to 550°C at a rate of 10°C / min And keep it warm for 4 hours. After the temperature in the furnace drops to room temperature, take it out and crush it through a 200-mesh sieve to obtain a carbon nitride / α-type iron oxide catalyst (denoted as CNFe2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com