A dual-ion battery using a ternary composite material as a negative electrode and a preparation method thereof

A composite material and dual-ion technology, applied in the field of electrochemical energy storage, can solve the problems of low theoretical specific capacity and poor rate performance, and achieve the effects of simple synthesis process, improved rate performance, and improved cycle stability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation method of sodium double-ion battery

[0026] Dissolve antimony trichloride, citric acid and cyanamide in sequence into a certain amount of graphene oxide suspension solution, then perform dehydration treatment to obtain a high-temperature carbonized precursor, and finally, in a tube furnace protected by an argon atmosphere at 700 ° C Carbonization treatment at high temperature for 40 minutes to obtain metal antimony / carbon / graphene ternary composite negative electrode.

[0027] A sodium double-ion battery was fabricated in a glove box, in which the positive electrode was commercial expanded graphite, the negative electrode was metal antimony / carbon / graphene ternary composite negative electrode, and the electrolyte was 1M sodium perchlorate (NaClO 4 ), and the diaphragm is a commercially available diaphragm. The voltage of the dual-ion battery is 2V-4.7V.

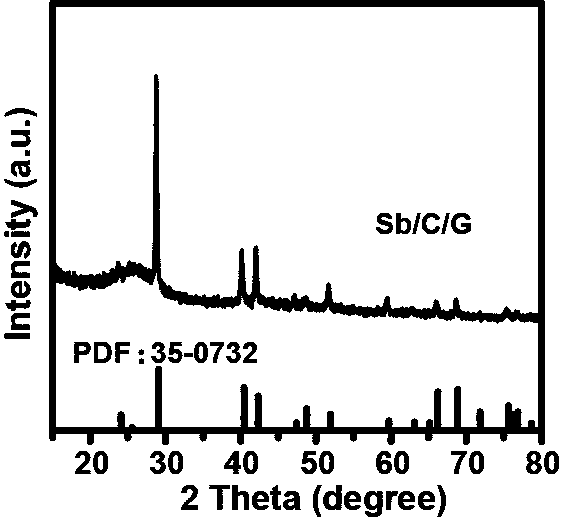

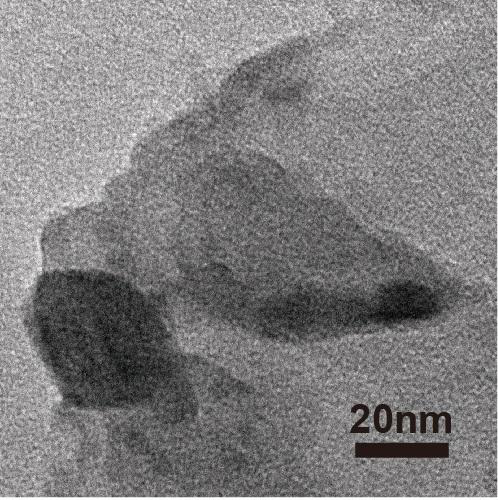

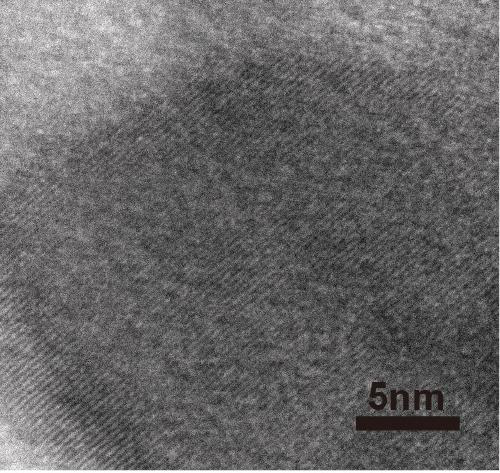

[0028] The metal antimony / carbon / graphene ternary composite negative electrode is ident...

Embodiment 2

[0030] Embodiment 2: preparation method of potassium double-ion battery

[0031] Dissolve tin tetrachloride, tartaric acid and melamine into a certain amount of graphene oxide suspension solution in sequence, then perform dehydration treatment to obtain a high-temperature carbonized precursor, and finally, carbonize at a high temperature of 900°C in a tube furnace protected by an argon atmosphere After processing for 50 minutes, a metal tin / carbon / graphene ternary composite negative electrode was obtained.

[0032] A potassium double-ion battery was fabricated in a glove box, wherein the positive electrode was commercial expanded graphite, the negative electrode was a metal tin / carbon / graphene ternary composite negative electrode, and the electrolyte was 1M potassium perchlorate (KClO 4 ), and the diaphragm is a commercially available diaphragm. The voltage of the dual-ion battery is 2V-5V.

Embodiment 3

[0033]Embodiment 3: Lithium double-ion battery preparation method

[0034] Dissolve zinc chloride, gluconic acid and cyanamide into a certain amount of graphene oxide suspension solution in sequence, and then perform dehydration treatment to obtain a high-temperature carbonized precursor. Lower carbonization treatment for 20 minutes to obtain metal zinc / carbon / graphene ternary composite negative electrode.

[0035] A lithium double-ion battery was fabricated in a glove box, in which the positive electrode was commercial expanded graphite, the negative electrode was a metal zinc / carbon / graphene ternary composite negative electrode, and the electrolyte was 1M lithium perchlorate (LiClO 4 ), and the diaphragm is a commercially available diaphragm. The voltage of the dual-ion battery is 3V-5V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com