A method for treating trivalent chromium complex wastewater and synchronously recovering chromium with reducing compound agent combined with ultraviolet light

A technology of ultraviolet light treatment and compound chemicals, which is applied in the direction of reduced water/sewage treatment, light water/sewage treatment, metallurgical wastewater treatment, etc., can solve the problems of high treatment cost, high conversion rate, and large output of chromium-containing sludge. Achieve the effect of avoiding the treatment process and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

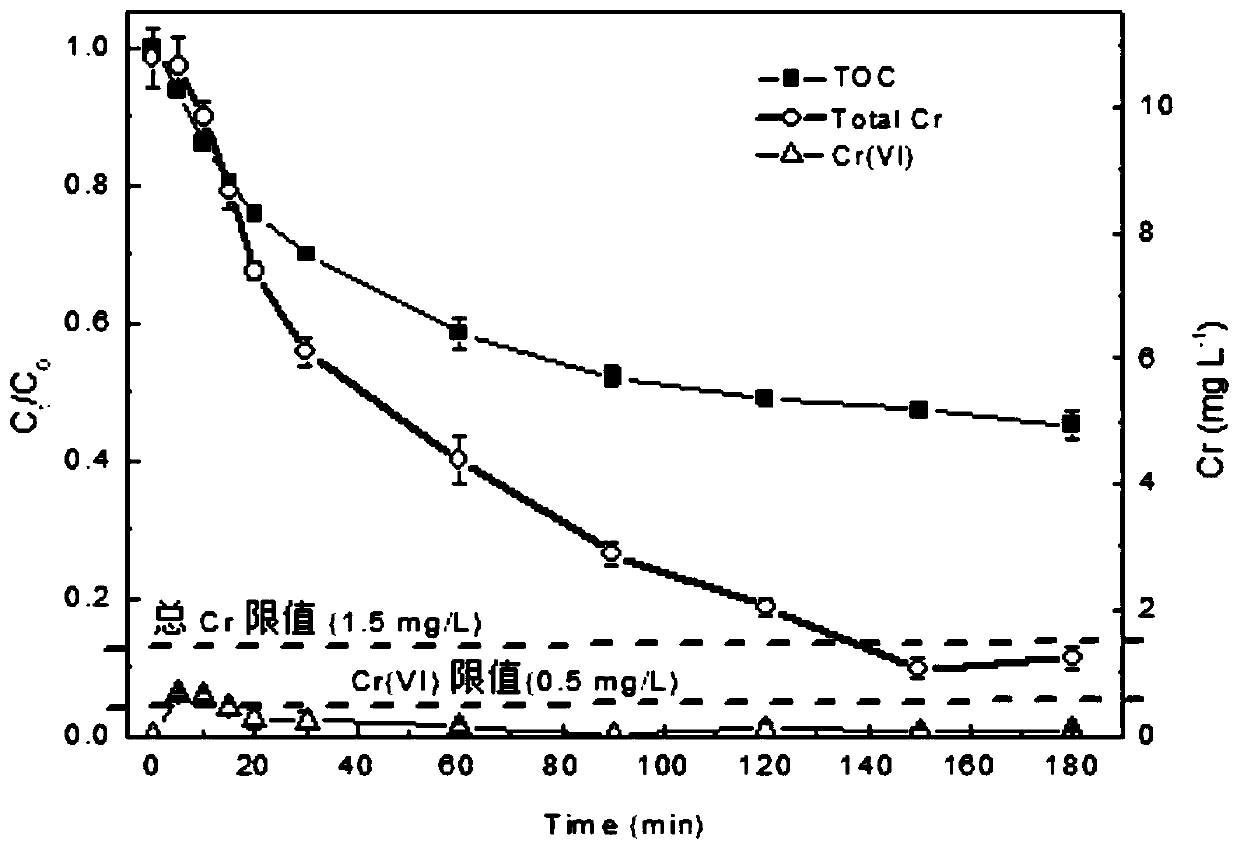

[0034] In this embodiment, a method of reducing compound reagents combined with ultraviolet light to treat trivalent chromium complex wastewater and chromium synchronously recovers, and tests the removal of chromium in 0.2mmol / L Cr-EDTA wastewater. The steps are:

[0035] A. Dosing: Add the reducing compound agent (compounded by ascorbic acid: hydroxylamine hydrochloride molar equivalent ratio = 1:1) to the wastewater of 0.2mmol / L Cr-EDTA and stir, the addition amount is 2mmol / L, the pH of the wastewater is initially The value is 3.5, the temperature is 25°C, and the pH of the wastewater is adjusted to 7 through sodium hydroxide solution;

[0036] B, ultraviolet light irradiation: the waste water of step A is processed 180min by the ultraviolet light irradiation (UV irradiation, wavelength<400nm) of medium-pressure mercury lamp, and chromium is separated out with light green precipitate form, and main component is dichromium trioxide;

Embodiment 2

[0041] In this embodiment, a method of reducing compound reagents combined with ultraviolet light to treat trivalent chromium complex wastewater and chromium synchronous recovery is applied to the removal of chromium in the wastewater of electroplating chemical industry parks. The initial pH is 2.3 and the initial chromium concentration is 23.8 mg / L. , the TOC concentration is 36mg / L, the steps are:

[0042] A. Dosing: Add a reducing compound agent with a molar ratio of 1:1 to Cr-EDTA (compounded by sodium sulfite: potassium sulfite molar equivalent ratio = 1:1) and stir. The initial pH value of the wastewater is 2.3, and the temperature is 25°C. Wastewater is adjusted to pH 8 by sodium hydroxide solution;

[0043] B, ultraviolet light irradiation: the waste water of step A is processed 180min by the ultraviolet light irradiation (UV irradiation, wavelength<400nm) of high-pressure mercury lamp, and chromium is separated out with light green precipitate form, and main component...

Embodiment 3

[0047] In this embodiment, a method of reducing complex medicament combined with ultraviolet light to treat trivalent chromium complex wastewater and chromium synchronous recovery, the test uses tap water to prepare Cr-citric acid wastewater with a concentration of 0.2mmol / L, pH=4, and a temperature of 25°C. The steps are:

[0048] A. Dosing: Add a reducing compound agent with a molar ratio of 1:2 to Cr-citric acid (compounded by ammonium sulfite:magnesium sulfite molar equivalent ratio = 1:1) and stir. The initial pH value of the wastewater is 4, and the temperature At 25°C, the pH of the wastewater was adjusted to 6 by sodium hydroxide solution;

[0049] B, ultraviolet light irradiation: the waste water of step A is processed 180min by the ultraviolet light irradiation (UV irradiation, wavelength<400nm) of amalgam ultraviolet lamp, chromium is separated out with the precipitate form of light green, and main component is dichromium trioxide;

[0050] C. Chromium recovery: re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com