Co-processing method of dioxins and heavy metals in fly ash based on steel slag and slag

A co-processing and heavy metal technology, applied to the removal of solid waste, etc., can solve the problems of huge difference in properties of dioxins and heavy metals, large energy consumption of heat treatment technology, increased difficulty of process control, etc., to solve the problem of low comprehensive utilization rate and low price , Reduce the effect of ball milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

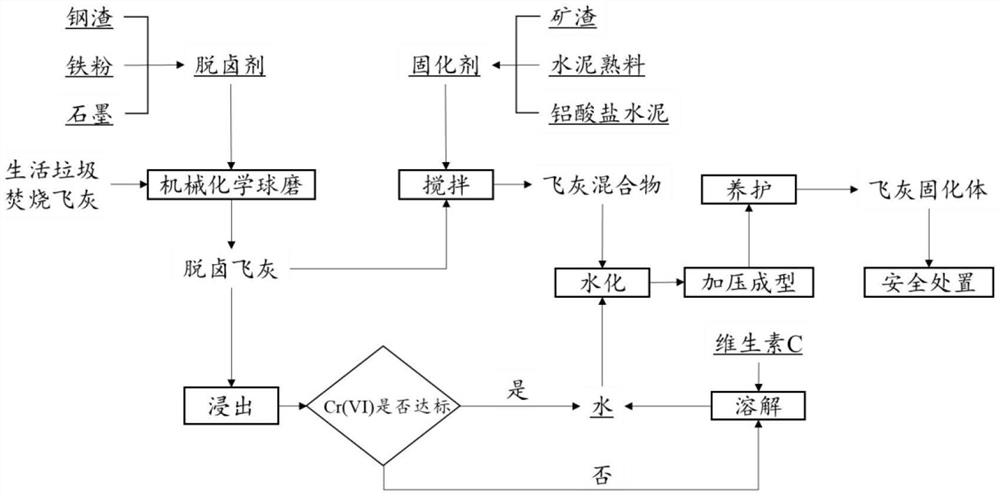

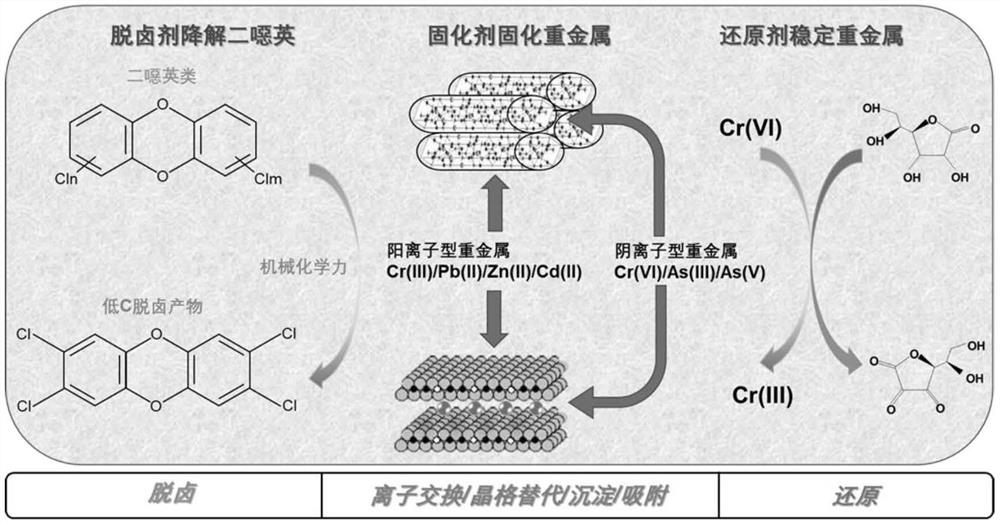

Method used

Image

Examples

Embodiment 1

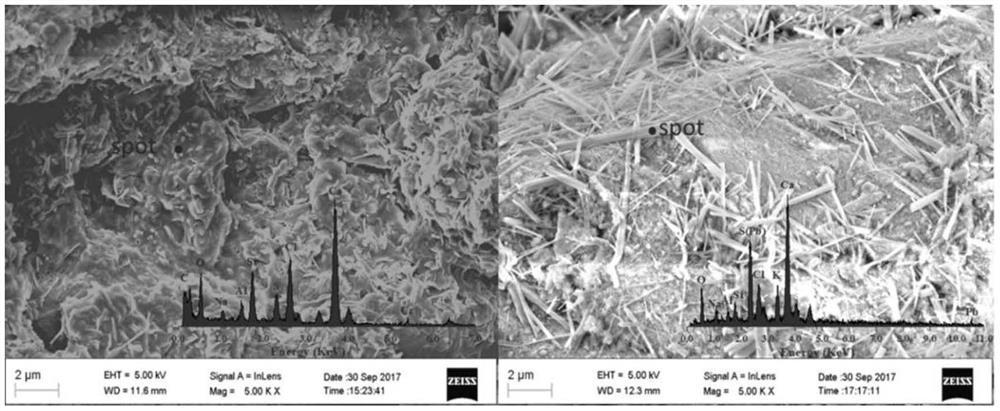

[0044] The object of treatment is the incineration fly ash produced during the normal operation of a waste incineration power plant. After drying, weigh 500g of the fly ash, add 80g of hot stuffy steel slag and 20g of graphite in a steel plant, mix them and put them into a planetary mill for ball milling. The ball milling time is 2h. The autorotation speed of the planetary mill is 1200r / min, and the revolution speed is 600r / min. After half an hour of ball milling, stop for 10 minutes and continue ball milling to obtain organochlorine-degraded fly ash; add 51 g of slag powder and 9 g of cement clinker to the organochlorine-degraded fly ash to obtain a fly ash mixture. Both slag powder and cement clinker are commercially available raw materials. Add 99g of water to the fly ash mixture, stir at 30r / min for 1min, mix well, pressurize and mold under a pressure of 30kN, and cure for 7 days to obtain a solidified fly ash body; perform a toxicity leaching test on the solidified fly a...

Embodiment 2

[0046] The object of treatment is the incineration fly ash produced during the normal operation of a waste incineration power plant. After drying, weigh 500g of the fly ash, add 70g of hot stuffy steel slag from a steel plant, 10g of iron powder, and 20g of graphite. After mixing, put it into a planetary mill for ball milling. The ball milling time is 4 hours. The autorotation speed of the planetary mill is 1200r / min, and the revolution speed is 600r / min. After every half hour of ball milling, stop for 10 minutes and continue ball milling to obtain organochlorine-degraded fly ash; add 102 g of slag powder and 18 g of aluminate cement to the organochlorine-degraded fly ash to obtain a fly ash mixture. Both slag powder and cement clinker are commercially available raw materials. Add 99 g of vitamin C solution with a concentration of 66 g / L to the fly ash mixture, stir at 30 r / min for 1 min, mix well, pressurize under a pressure of 30 kN, and maintain for 7 days to obtain a soli...

Embodiment 3

[0048] The object of treatment is the waste incineration fly ash in Case 1. After drying, weigh 500g of the fly ash, add 80g of hot stuffy steel slag and 20g of graphite in a steel plant, mix them and put them into a planetary mill for ball milling. The ball milling time is 3 hours. The autorotation speed of the planetary mill is 1200r / min, and the revolution speed is 600r / min. Stop ball milling for 10 minutes after each ball mill for half an hour to obtain organochlorine-degraded fly ash; add 51 g of slag powder and 9 g of aluminate cement to the organochlorine-degraded fly ash to obtain a fly ash mixture. Both slag powder and cement clinker are commercially available raw materials. Add 99g of water to the fly ash mixture, stir at 30r / min for 1min, mix well, pressurize and mold under a pressure of 30kN, and cure for 7 days to obtain a solidified fly ash body; perform a toxicity leaching test on the solidified fly ash , the leaching concentration of excessive heavy metal Pb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com