High strength cold-rolled steel sheet excellent in ductility, hole-forming property and surface treatment property, molten galvanized steel sheet, and method for manufacturing same

A hot-dip galvanized steel sheet, surface treatment technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve problems such as poor water cutting, poor coating, uneven coating, etc. High availability, excellent ductility and pore expandability, and excellent phosphate treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

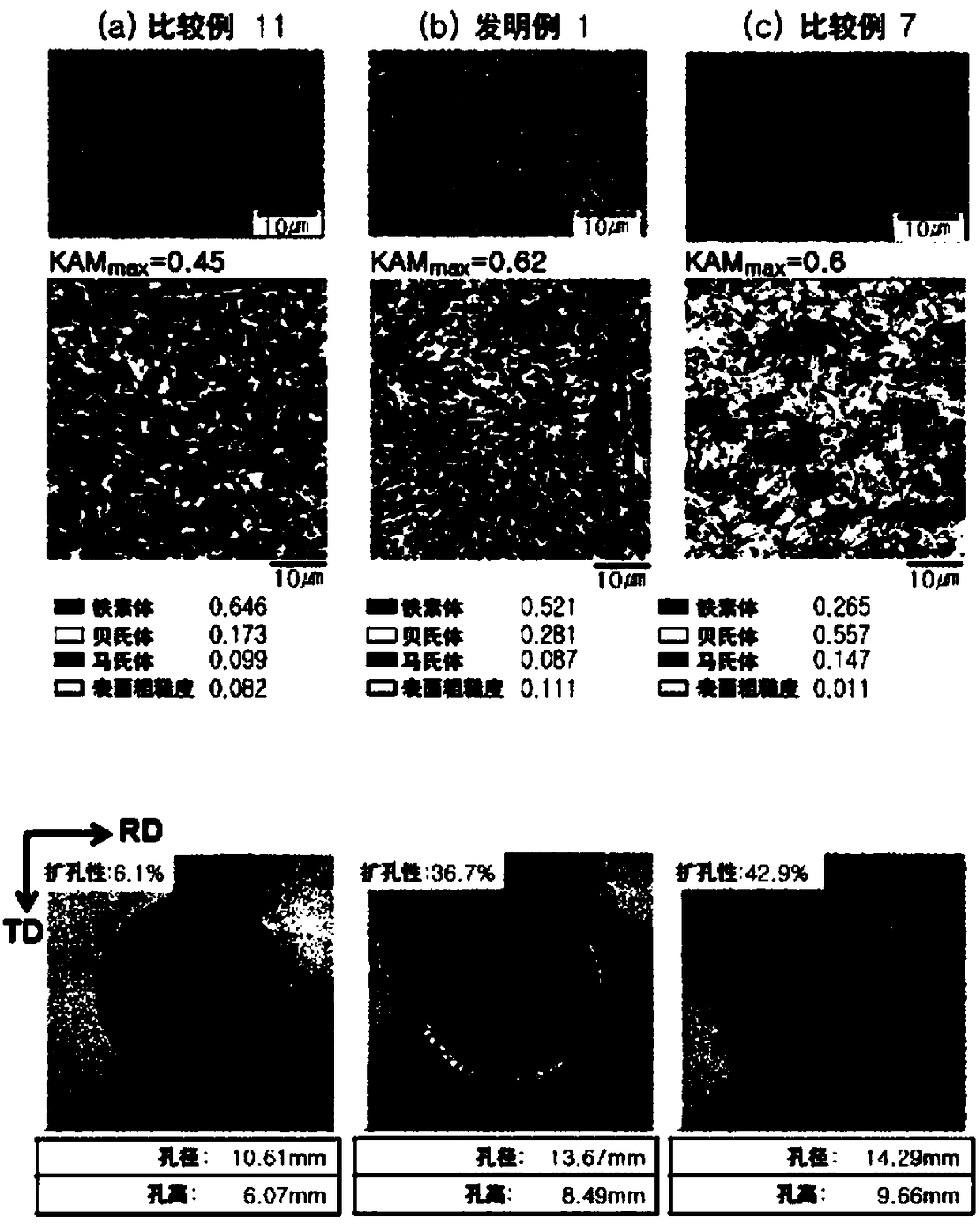

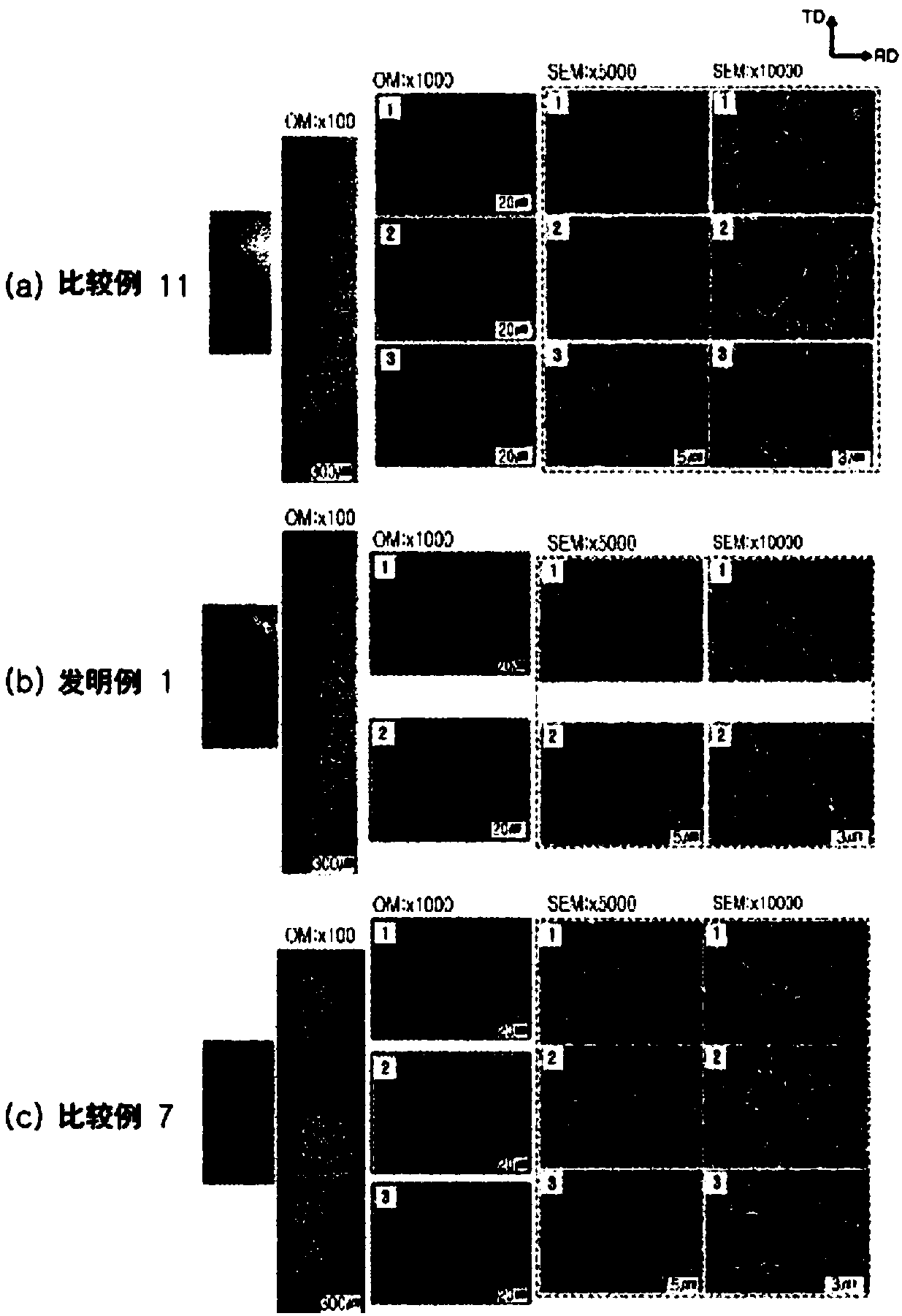

[0116] Hereinafter, the present invention will be described in more detail through examples.

[0117] A molten metal having the composition shown in Table 1 below was produced by vacuum melting into a steel ingot having a thickness of 90 mm and a width of 175 mm. Next, the steel ingot was further heated at 1200° C. for one hour to perform homogenization treatment, and then hot finish rolling was performed at a temperature of Ar3 or higher, that is, a temperature of 900° C. or higher to produce a hot-rolled steel sheet. Then, after cooling the hot-rolled steel sheet, it was loaded into a furnace preheated to 600° C. and maintained for one hour, and then furnace-cooled to simulate hot-rolled coiling. Then, the hot-rolled sheet was cold-rolled at a cold reduction ratio of 50 to 60%, and then annealed and heat-treated under the conditions of Table 2 below to manufacture a final cold-rolled steel sheet.

[0118] [Table 1]

[0119]

[0120] In the above-mentioned Table 1, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com