High-calcium-salt drilling fluid and preparation method thereof

A drilling fluid and high-calcium technology, applied in the field of drilling, can solve the problems of difficult control of fluid loss, deterioration of drilling fluid performance, and insufficient temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

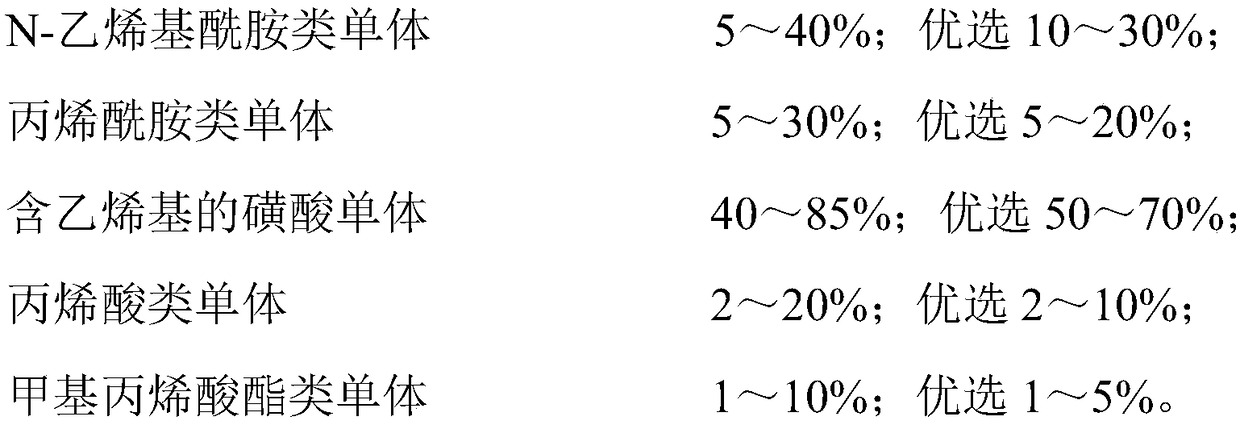

[0046] Preparation of anti-calcium fluid loss reducer:

[0047] (1) Add 10g N-vinylformamide, 6g acrylamide, 80g 2-acrylamido-2-methylpropanesulfonic acid, 2.5g acrylic acid, 1.5g methyl methacrylate into 150g deionized water, and use 40g 40% sodium hydroxide solution adjusts the pH value at 8 to obtain mixed solution A, and the total concentration of monomers in mixed solution A is 34.5%

[0048] (2) Add 0.3g xanthan gum in mixed solution A, pass N 2 After 0.5 hour, mixed solution B was obtained, wherein xanthan gum was 0.1% by weight of mixed solution B.

[0049](3) Add 0.05 g of initiator ammonium persulfate and sodium bisulfite and 0.3 g of complexing agent disodium edetate to mixed solution B at 50° C., and react for 3 hours to obtain a gel-like product, wherein The initiator dose is 0.1% of the total weight of the monomer; disodium edetate is 0.1% of the weight of the mixed solution B;

[0050] (4) Shearing and granulating the gel product, drying at 85° C. for 10 hou...

Embodiment 1

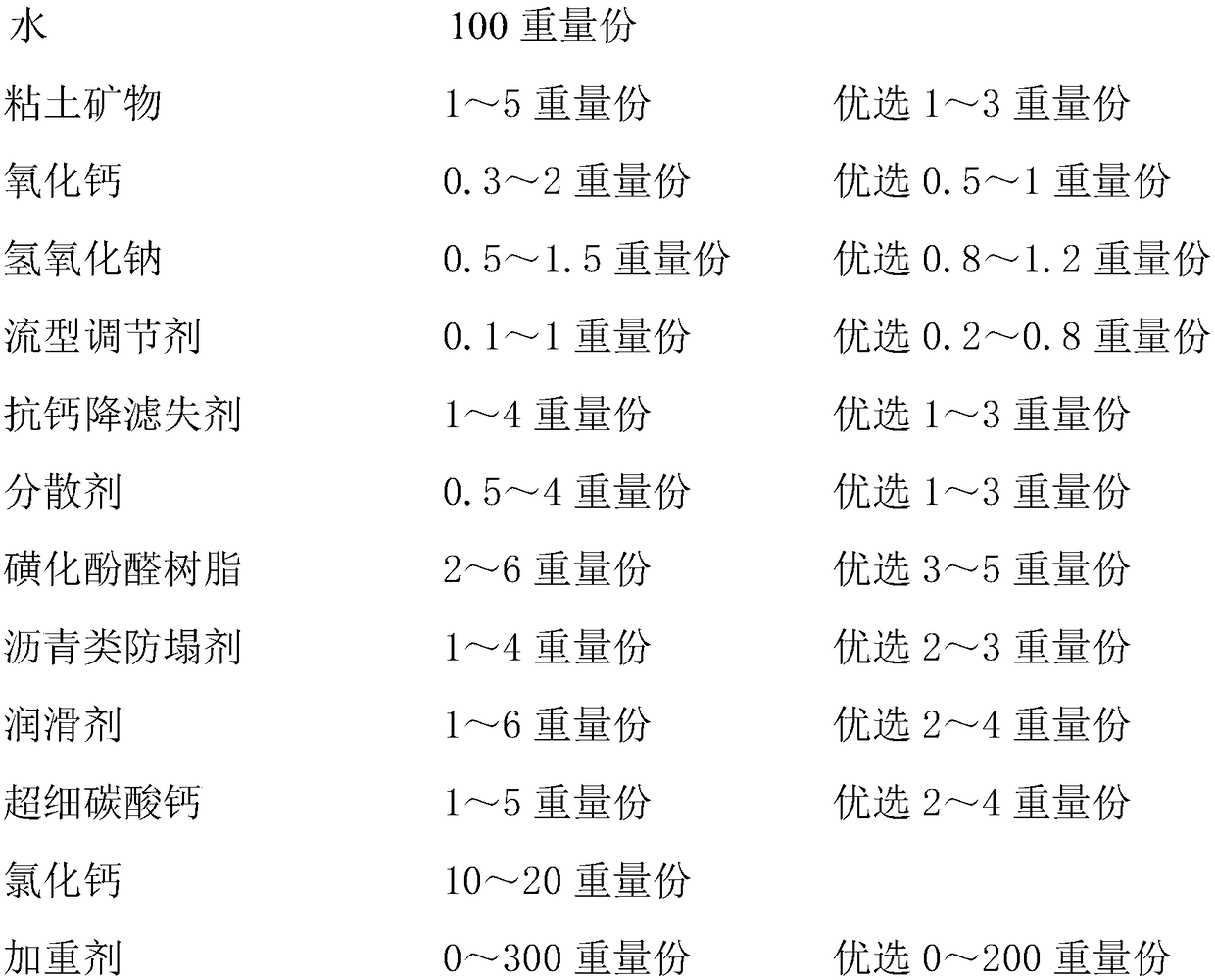

[0084] The density is 1.3g / cm 3 The distribution ratio of drilling fluid components is as follows based on 100 parts by weight of water:

[0085]

[0086]

[0087] The specific preparation process is as follows:

[0088] (1) Under stirring, disperse sodium bentonite and attapulgite in water, and place at room temperature for more than 24 hours; (2) Add calcium oxide and 10% sodium hydroxide aqueous solution, and stir at high speed for 5 minutes; (3) Under high stirring, Slowly add xanthan gum and anti-calcium fluid loss reducer in sequence, and stir at high speed for 30 minutes until they are completely dissolved; Calcium carbonate, stir at high speed for 10 minutes; (5) Add calcium chloride, stir at high speed for 20 minutes, then add barite and stir for 10 minutes.

[0089] Prepare high-calcium salt drilling fluid according to the above process, pour it into the aging tank, roll it at 135°C for 16 hours, cool down, measure the rheological properties with a six-speed ...

Embodiment 2

[0098] The density is 1.6g / cm 3 The distribution ratio of drilling fluid components is as follows based on 100 parts by weight of water:

[0099]

[0100] Concrete preparation process is with embodiment 1:

[0101] Prepare high-calcium salt drilling fluid according to the above process, pour it into the aging tank, roll it at 150°C for 16 hours, cool down, measure the rheological properties with a six-speed viscometer at 50°C, and then measure the medium pressure filtration loss and high temperature and high pressure Filtration. The performance of the high calcium drilling fluid with the above composition ratio is as follows:

[0102] table 3

[0103]

[0104] As can be seen from the above results, the high-calcium drilling fluid containing 10% calcium chloride of the present invention has a plastic viscosity of 56mPa.s after aging at 135°C / 16 hours, and a medium pressure fluid loss of 2.1mL after aging. The high-pressure fluid loss is 15mL, indicating that the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Plastic viscosity | aaaaa | aaaaa |

| Plastic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com