Core board material of vacuum insulation board for buildings

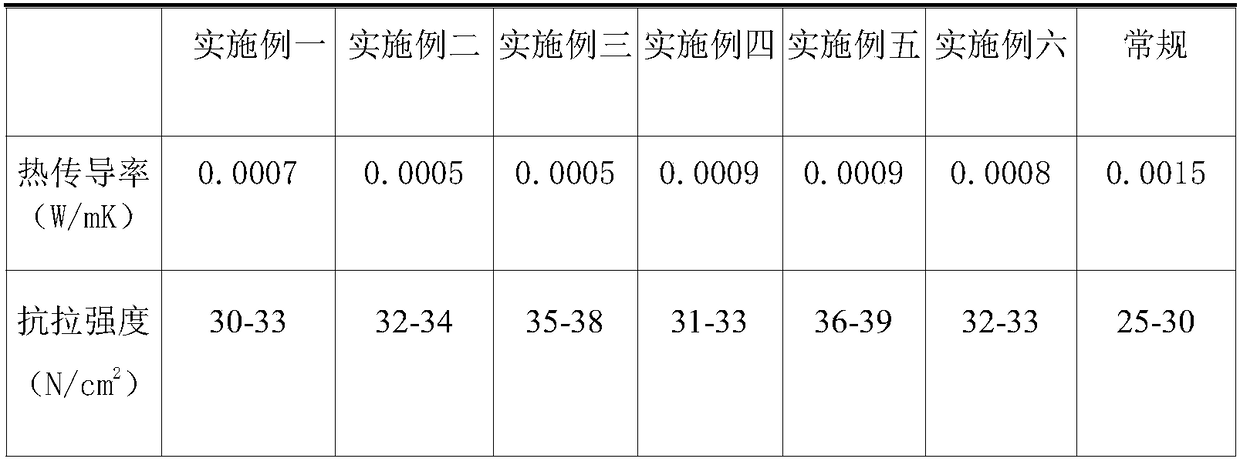

A technology for vacuum insulation panels and buildings, which is applied in building components, insulation improvement, climate change adaptation, etc. It can solve the problem that the core material does not have pressure resistance stability and thermal insulation stability, and thermal inertia and thermal insulation do not meet strict requirements. , high thermal conductivity and other issues, to achieve excellent thermal inertia and heat insulation effect, improve processing convenience, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1. A vacuum insulation board core board material for construction, comprising the following raw materials in parts by weight: 18 parts of glass fiber, 23 parts of mineral wool, 22 parts of silicon dioxide, 14 parts of calcium chloride hexahydrate, 8 parts of quicklime, 6 parts of acrylic acid, 7 parts of polyvinyl alcohol, 4 parts of potassium bisulfite, 13 parts of bentonite, 11 parts of quartz sand, 9 parts of magnesium oxide, 5 parts of zinc oxide, 30 parts of deionized water, of which rock wool fiber accounts for 20 copies;

[0028] Its preparation method includes the following steps: S1: Add acrylic acid and deionized water into the reactor, stir at room temperature at a stirring speed of 5 rpm for 4 minutes, then add calcium chloride hexahydrate and quicklime, and heat up to 25°C, stirred at a stirring speed of 8rpm for 6min, then added polyvinyl alcohol, potassium bisulfite and bentonite, raised the temperature to 35°C at a speed of 4°C / min, stirred at...

Embodiment 2

[0032] Embodiment 2, a kind of core plate material of vacuum insulation board for building, comprises the raw material of following weight parts: 19 parts of glass fiber, 24 parts of mineral wool, 23 parts of silicon dioxide, 15 parts of calcium chloride hexahydrate, 9 parts of quicklime, 7 parts of acrylic acid, 8 parts of polyvinyl alcohol, 5 parts of potassium bisulfite, 14 parts of bentonite, 12 parts of quartz sand, 10 parts of magnesium oxide, 6 parts of zinc oxide, 31 parts of deionized water, of which rock wool fiber accounts for 21 copies;

[0033] Its preparation method includes the following steps: S1: Add acrylic acid and deionized water into the reactor, stir at room temperature at a stirring speed of 6 rpm for 5 minutes, then add calcium chloride hexahydrate and quicklime, and heat up to Stir at 26°C for 7min at a stirring speed of 9rpm, then add polyvinyl alcohol, potassium bisulfite and bentonite, raise the temperature to 36°C at a speed of 5°C / min, stir for 12mi...

Embodiment 3

[0037] Embodiment 3, a kind of core board material of vacuum insulation board for building, comprises the raw material of following weight part: 21 parts of glass fiber, 25 parts of mineral wool, 25 parts of silicon dioxide, 17 parts of calcium chloride hexahydrate, 11 parts of quicklime, 8 parts of acrylic acid, 10 parts of polyvinyl alcohol, 7 parts of potassium bisulfite, 15 parts of bentonite, 13 parts of quartz sand, 12 parts of magnesium oxide, 7 parts of zinc oxide, 34 parts of deionized water, of which rock wool fiber accounts for 24 copies;

[0038] Its preparation method includes the following steps: S1: Add acrylic acid and deionized water into the reaction kettle, stir at room temperature at a stirring speed of 9 rpm for 6 minutes, then add calcium chloride hexahydrate and quicklime, and heat up to 29°C, stirred at a stirring speed of 11rpm for 8min, then added polyvinyl alcohol, potassium bisulfite and bentonite, raised the temperature to 39°C at a speed of 5°C / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com