Bivalent manganese-doped full inorganic perovskite quantum dot glass as well as preparation method and application thereof

A technology of quantum dot glass and inorganic calcium, which is applied in glass manufacturing equipment, glass molding, chemical instruments and methods, etc., can solve the problems of poor heat resistance and light aging resistance, low luminous efficiency of powder, and limited application, etc., to achieve Low cost, uniform and stable product, and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

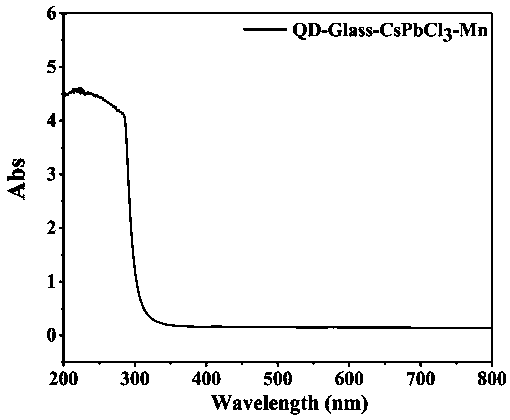

Image

Examples

Embodiment 1

[0030] The molar percentage of the glass chemical composition of the present embodiment is: 30B 2 o 3 - 40SiO 2 - 5ZnO- 7Al 2 o 3 - 6Cs 2 CO 3 -4(Pb / Mn)Cl 2 - 4NaCl- 4MCO 3 , where M is Sr.

[0031] Table 1 Raw material composition of the all-inorganic perovskite quantum dot glass doped with divalent manganese in Example 1

[0032]

[0033] The mass of each compound shown in Table 1 can be obtained by calculating the molar percentage of the chemical composition in Example 1. Accurately weigh analytically pure boric acid (H 3 BO 3 ), silicon dioxide (SiO 2 ), alumina (Al 2 o 3 ), cesium carbonate (Cs 2 CO 3 ), lead chloride (PbCl 2 ), manganese chloride (MnCl 2 ), sodium chloride (NaCl), strontium carbonate (SrCO 3 ) zinc oxide (ZnO). Grind the precisely weighed raw material in an agate mortar for 1–2 h, transfer it to a corundum crucible, melt it at 1200°C for 30 min, pour the melt into a preheated graphite mold, and put it into a Annealed in the furnace...

Embodiment 2

[0035] The molar percentage of the glass chemical composition of the present embodiment is: 35B 2 o 3 - 35SiO 2 - 4ZnO- 7Al 2 o 3 - 6Cs 2 CO3 -4(Pb / Mn)Cl 2 - 4NaCl- 5MCO 3 , where M is Ca.

[0036] Table 2 Raw material composition of the all-inorganic perovskite quantum dot glass doped with divalent manganese in Example 2

[0037] raw material

[0038] Calculated according to the mole percentage of the chemical composition in Example 2, the mass of each compound as shown in Table 2 can be obtained. Accurately weigh analytically pure boric acid (H 3 BO 3 ), silicon dioxide (SiO 2 ), alumina (Al 2 o 3 ), cesium carbonate (Cs 2 CO 3 ), lead chloride (PbCl 2 ), manganese chloride (MnCl 2 ), sodium chloride (NaCl), calcium carbonate (CaCO 3 ) zinc oxide (ZnO). The precisely weighed raw materials were ground in an agate mortar for 1–2 h, then transferred to a corundum crucible, melted at 1300 °C for 30 min, and then poured into a preheated graphite mold f...

Embodiment 3

[0040] The mole percentage of the glass chemical composition of the present embodiment is: 34B 2 o 3 -38SiO 2 - 4ZnO- 5Al 2 o 3 - 6Cs 2 CO 3 -4(Pb / Mn)Cl 2 - 4NaCl- 5MCO 3 , where M is Sr.

[0041] Table 3 Raw material composition of all-inorganic perovskite quantum dot glass doped with divalent manganese in Example 3

[0042] raw material

[0043] The mass of each compound shown in Table 3 can be obtained by calculating the molar percentage of the chemical composition in Example 3. Accurately weigh analytically pure boric acid (H 3 BO 3 ), silicon dioxide (SiO 2 ), alumina (Al 2 o 3 ), cesium carbonate (Cs 2 CO 3 ), lead chloride (PbCl 2 ), manganese chloride (MnCl 2 ), sodium chloride (NaCl), strontium carbonate (SrCO 3 ) zinc oxide (ZnO). Grind the precisely weighed raw material in an agate mortar for 1–2 h, transfer it to a corundum crucible, melt it at 1250°C for 30 min, pour the melt into a preheated graphite mold, and put it into a Annealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com